Efficient direct-current generator

A DC generator, high-efficiency technology, applied in the direction of DC commutators, electrical components, electromechanical devices, etc., can solve the problems of DC generator structure complexity, energy loss, etc., to improve power generation efficiency, increase power generation, and reduce load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

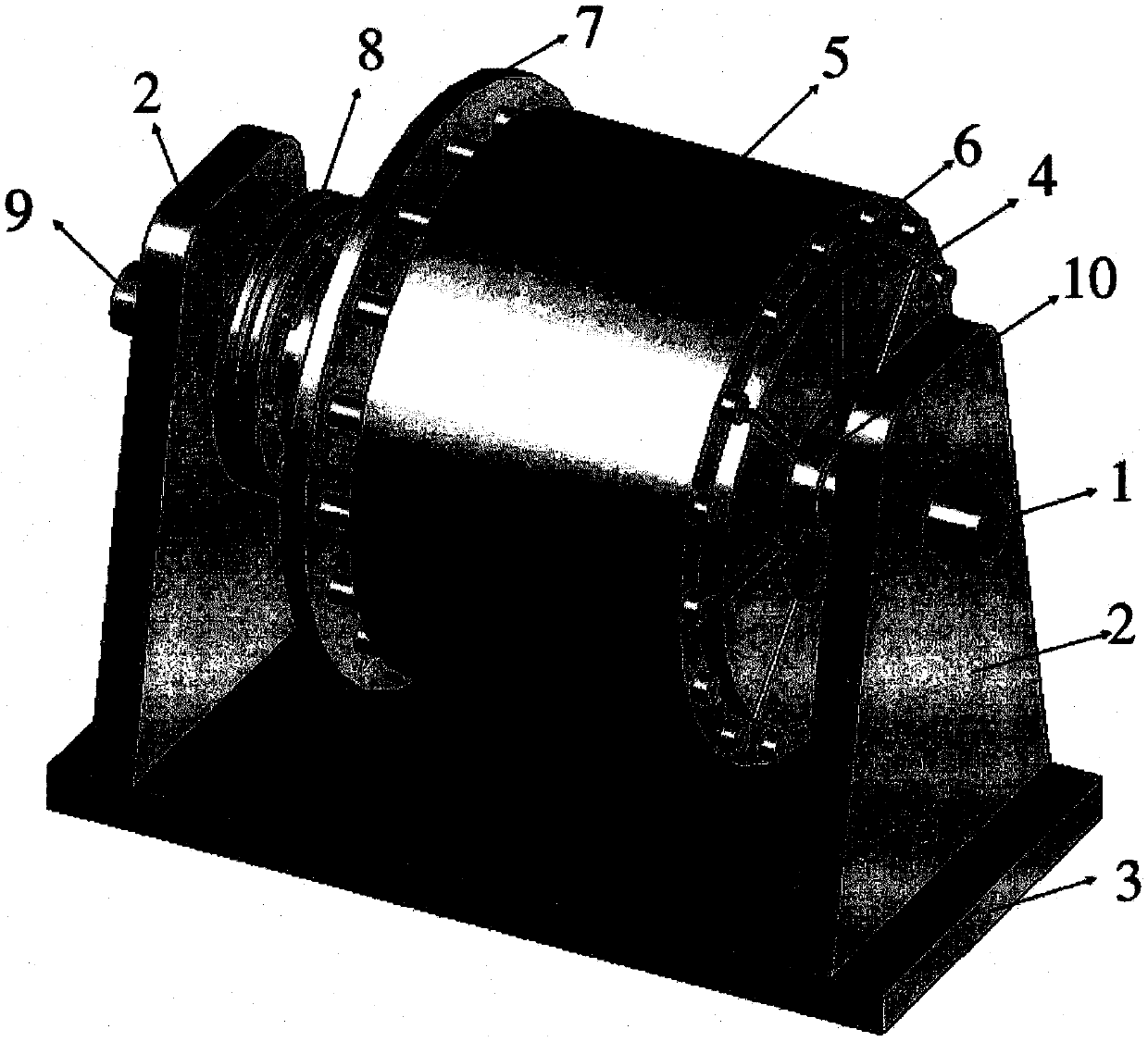

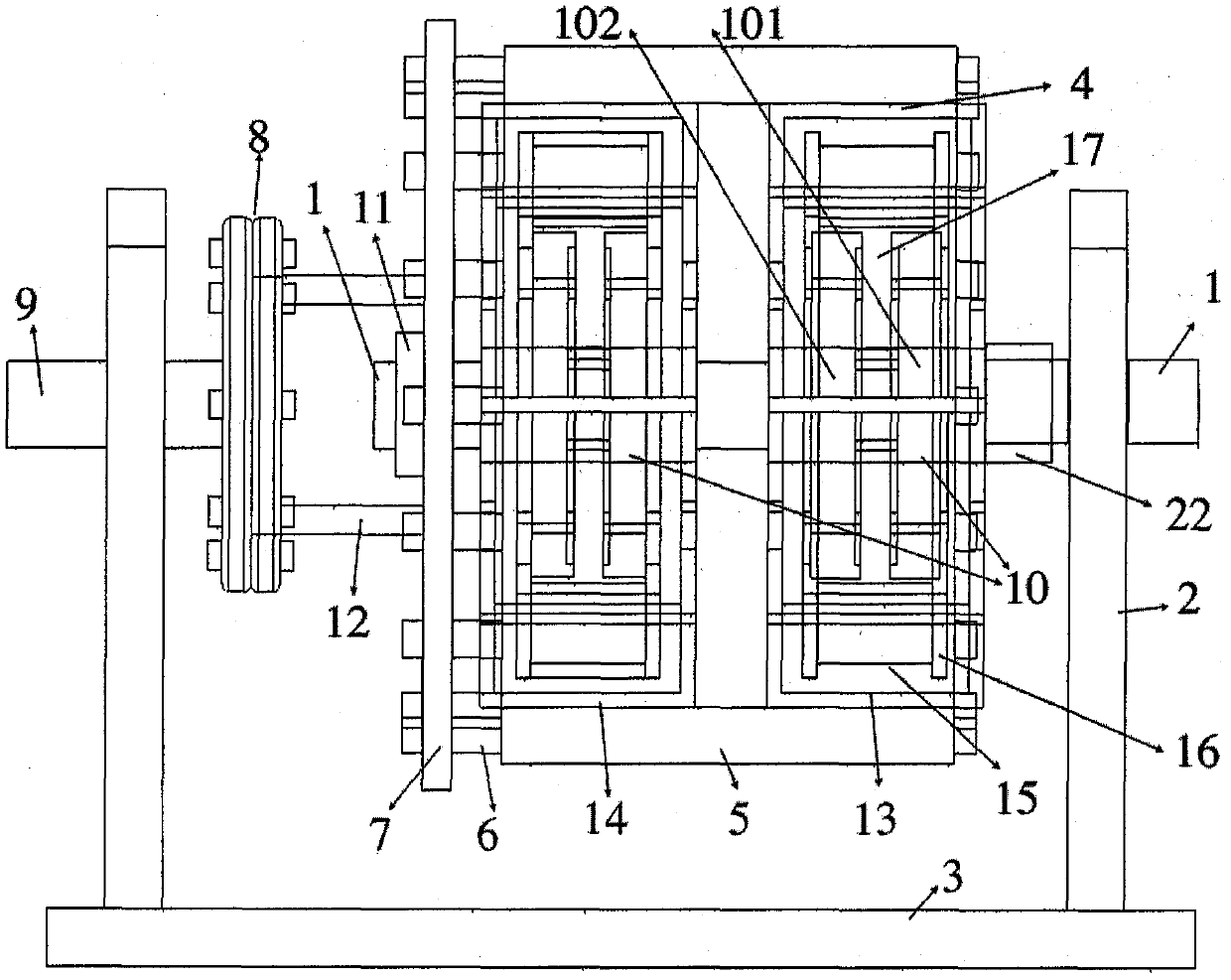

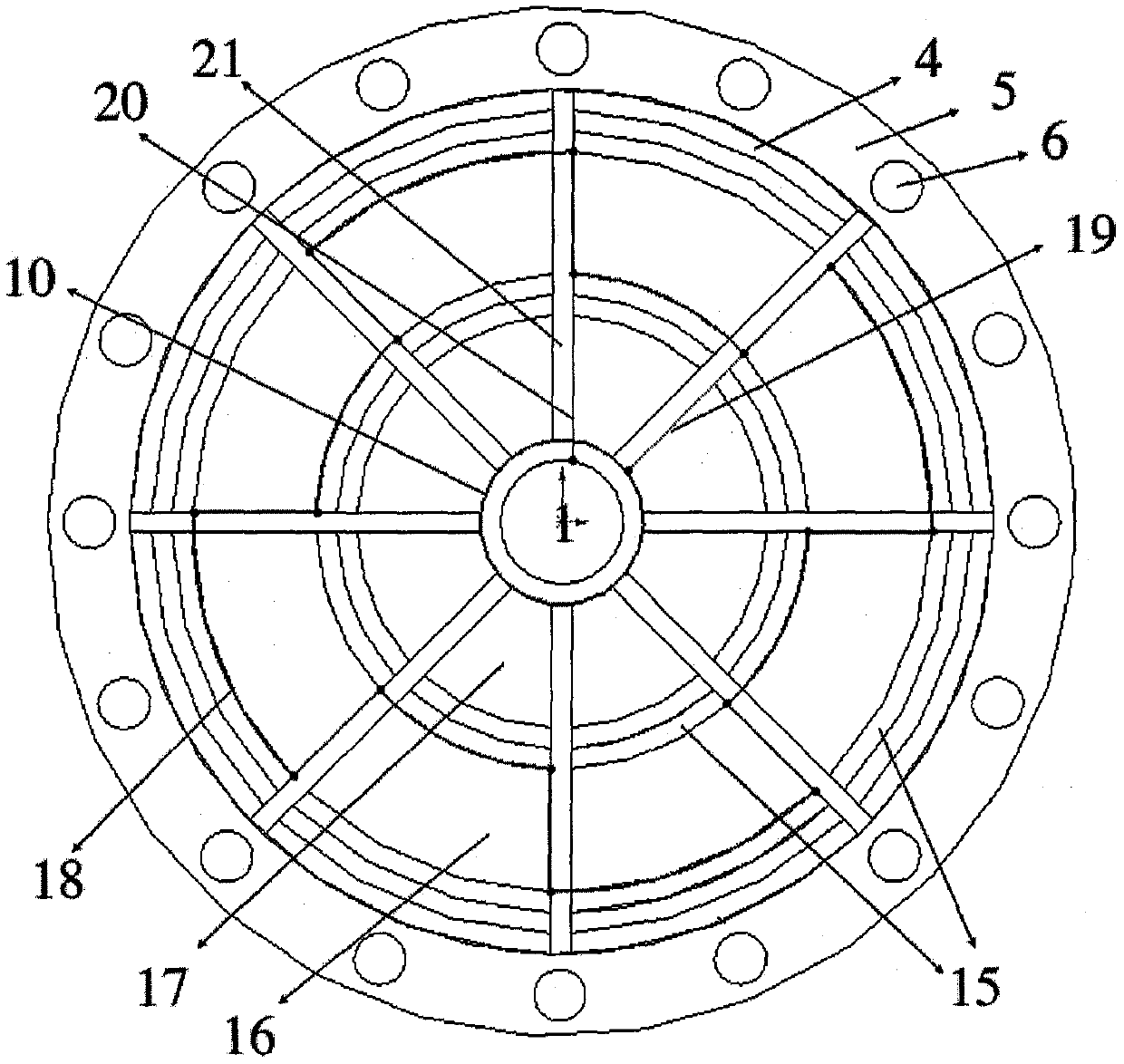

[0027] The overall structure of a high-efficiency DC generator is as follows: figure 1 As shown, the generator shown in this figure is a single-turn two-stage generator. For other details, see figure 2 to Figure 4 . The generator is fixed on the base 3 through the support frame 2, the coil axis 1 and the magnetic field axis 9 are coaxially fixed on the support frame, and the coil axis 1 and the magnetic field axis 9 are respectively driven to rotate in opposite directions by external force, and a uniform magnetic field is produced by the horseshoe magnet 4 , In the present embodiment, 8 horseshoe-shaped magnets are constructed into a single-circle annular magnetic field, and the directions of the magnetic fields of adjacent horseshoe-shaped magnets are opposite (see Figure 4 ), there are narrow gaps 21 therebetween, and all horseshoe magnets are fixed by the magnetic field cover 5 . In order to drive the ring-shaped magnetic field circle to rotate, the connecting rod 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com