Hot-press conversion vapor chamber

A technology of temperature equalization plate and main board, which is applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc. problem, to achieve the effect of sufficient heat transfer process, avoiding stable laminar flow, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

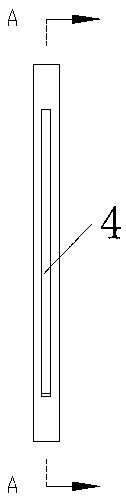

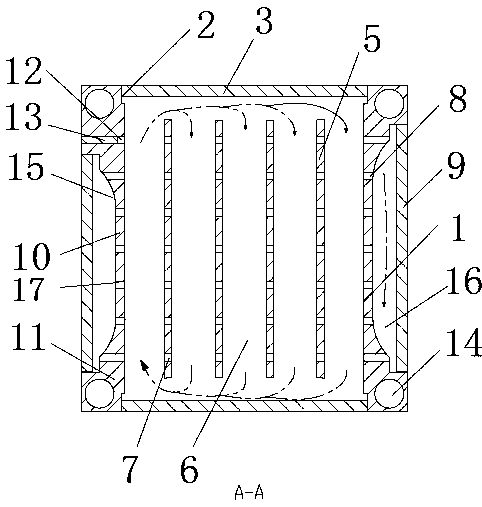

[0028] Such as figure 1 , figure 2 with image 3 As shown, a thermo-compression conversion chamber provided by the present invention includes: a rectangular main board 1, the main board is provided with a sealing port 2 above and below, and a matching sealing strip 3 is installed on the sealing port. A cavity 4 is provided in the main board; a plurality of first deflectors 5 arranged side by side with the sides of the main board are arranged in the cavity, and a plurality of first deflectors divide the inner cavity into a plurality of deflectors. Channel 6; the two ends of the first deflector plate form a gap with the corresponding inner wall of the cavity; the first deflector plate is provided with a plurality of first guide holes 7; the left and right sides of the main board have inner plates 8 And the outer heat conduction plate 9 for contacting the heat source, the inner plate includes a second deflector 10 and two ends 11, the two ends of the second deflector are used ...

Embodiment 2

[0032] Such as Figure 4As shown, the difference between Embodiment 2 and Embodiment 1 is that a spherical rotatable spoiler ball 18 is installed in the first guide hole, and the two ends of the spoiler ball partially protrude outward from the first guide hole. In the baffle, the inner side wall of the first diversion hole is a curved surface compatible with the spoiler ball, and the spoiler ball is provided with a horn hole 19, and the inner diameter of one end of the horn hole is larger than the inner diameter of the other end. The outer side of the larger end of the horn hole is provided with a spoiler 20, the curvature of the outer surface of the spoiler is greater than the curvature of the inner surface; The steering limit piece 21 in the direction of the flow plate.

[0033] When this embodiment is implemented, the fluid passes through the first diversion hole, and the turbulent flow produced by the spoiler ball avoids a stable laminar flow, and at the same time makes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com