Electric operated valve

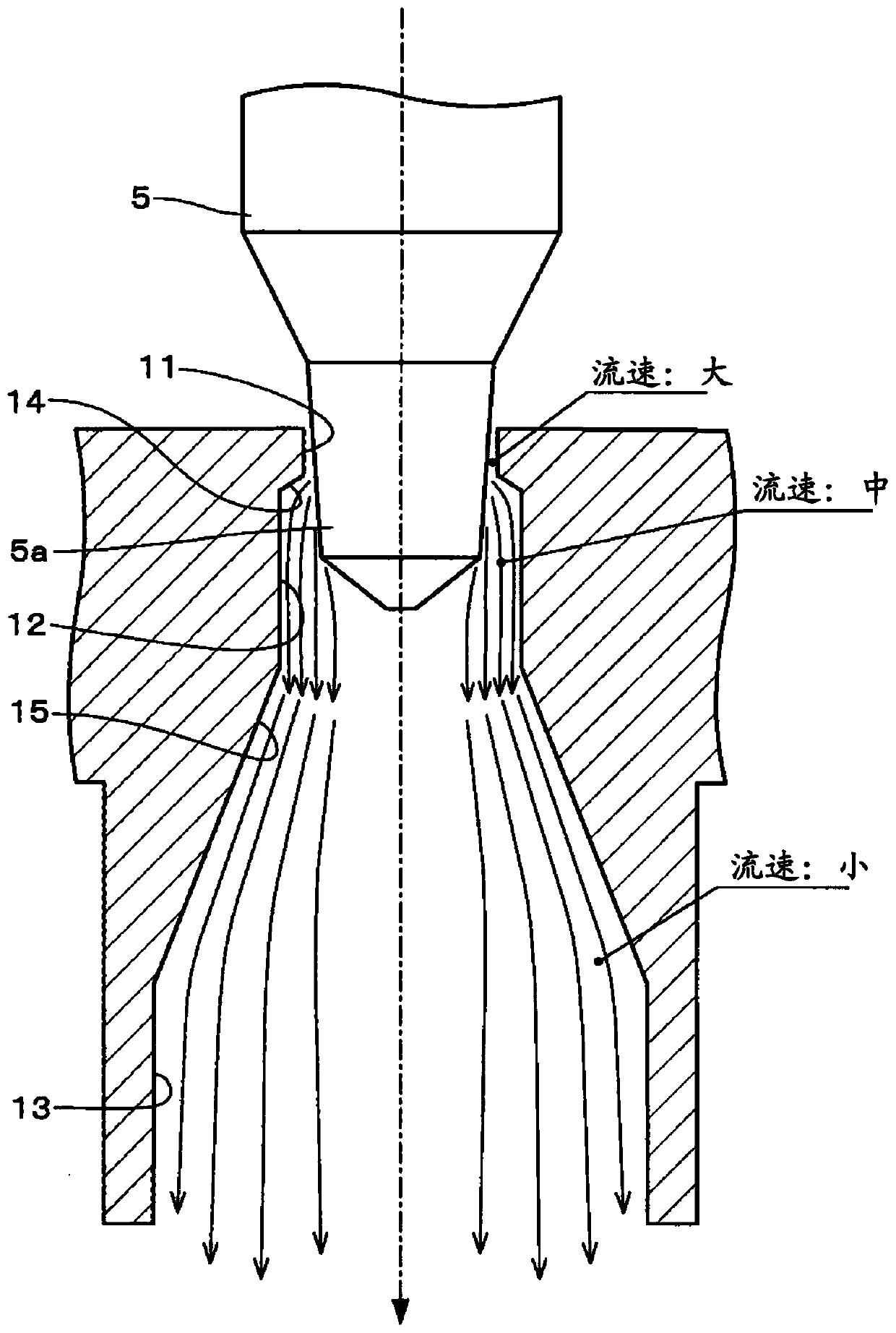

一种电动阀、阀口的技术,应用在升阀、阀细节、阀装置等方向,能够解决流速不减速、噪声大、阀口差压高等问题,达到减少流速音、减少噪声、抑制破裂的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

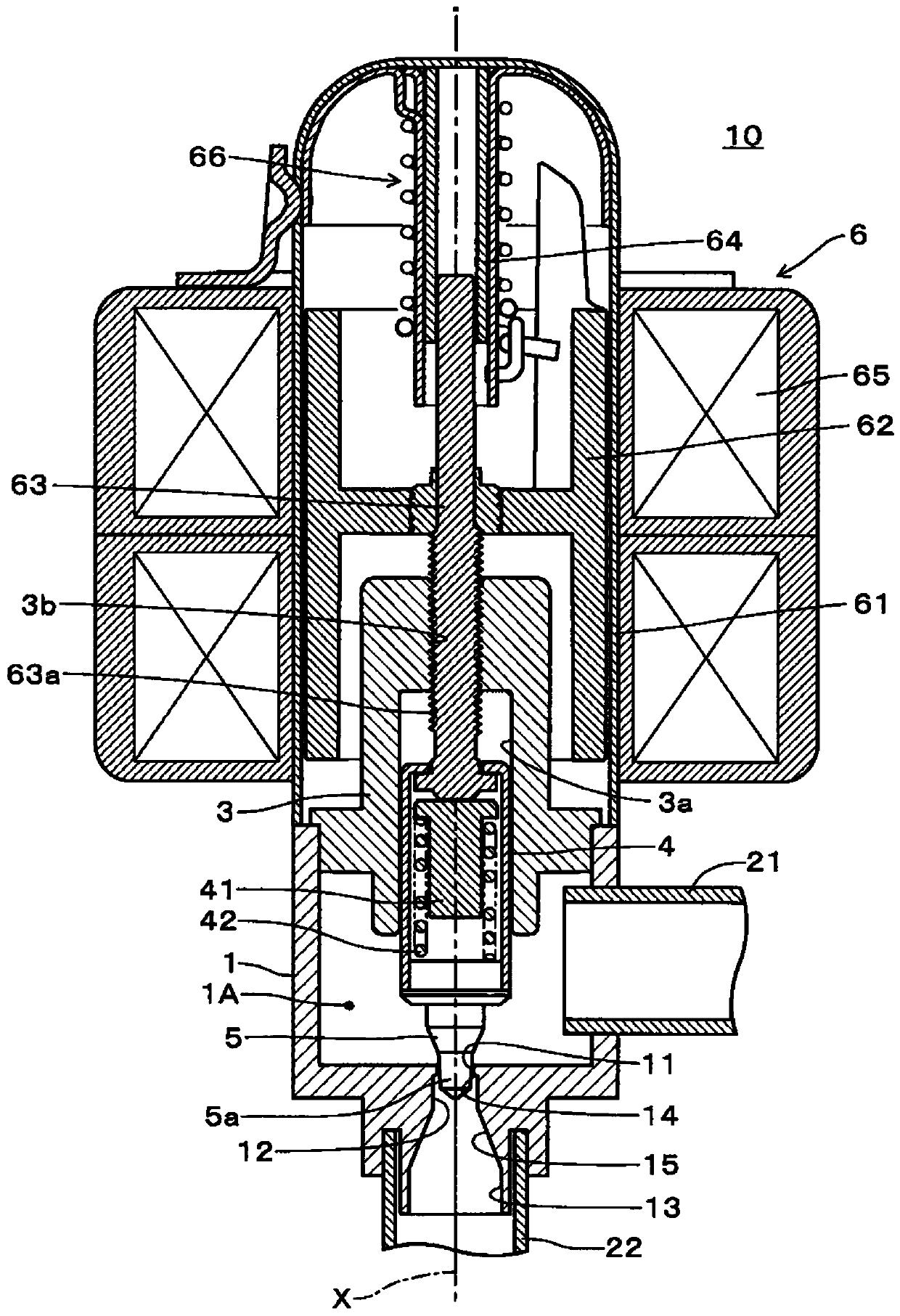

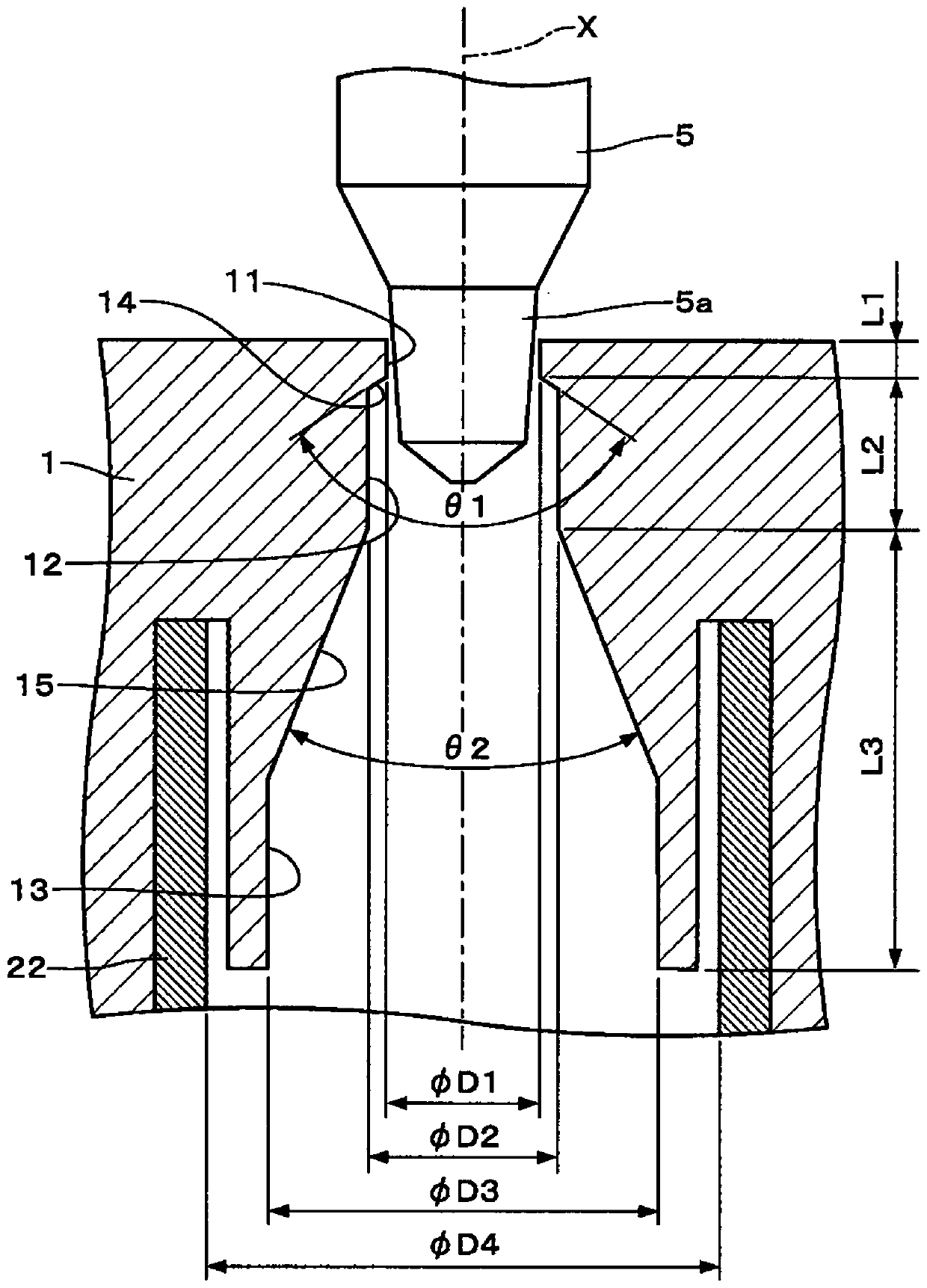

[0034] Next, embodiments of an electric valve according to the present invention will be described with reference to the drawings. figure 1 is a longitudinal sectional view of the electric valve of the embodiment, figure 2 It is an enlarged longitudinal sectional view of main parts near the valve port of the electric valve according to the embodiment, image 3 It is a figure explaining the function of the valve port of the electric valve of embodiment, Figure 4 It is a figure which shows an example of the air conditioner which used the electric valve which concerns on embodiment.

[0035] First, based on Figure 4 The air conditioner of embodiment is demonstrated. The air conditioner has the electric valve 10 of the embodiment, the outdoor heat exchanger 20 mounted on the outdoor unit 100, the indoor heat exchanger 30 mounted on the indoor unit 200, the flow path switching valve 40, and the compressor 50, and these elements are passed through The pipes are connected as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com