Dehydroxylation annealing method for large-sized optical fiber preforms

An optical fiber preform, large-size technology, applied in the field of optical fiber manufacturing, can solve problems such as generating thermal stress, and achieve the effects of improving efficiency and output, ensuring stability, and improving thermal insulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the present invention clearer, it will now be explained in detail in conjunction with the accompanying drawings and embodiments.

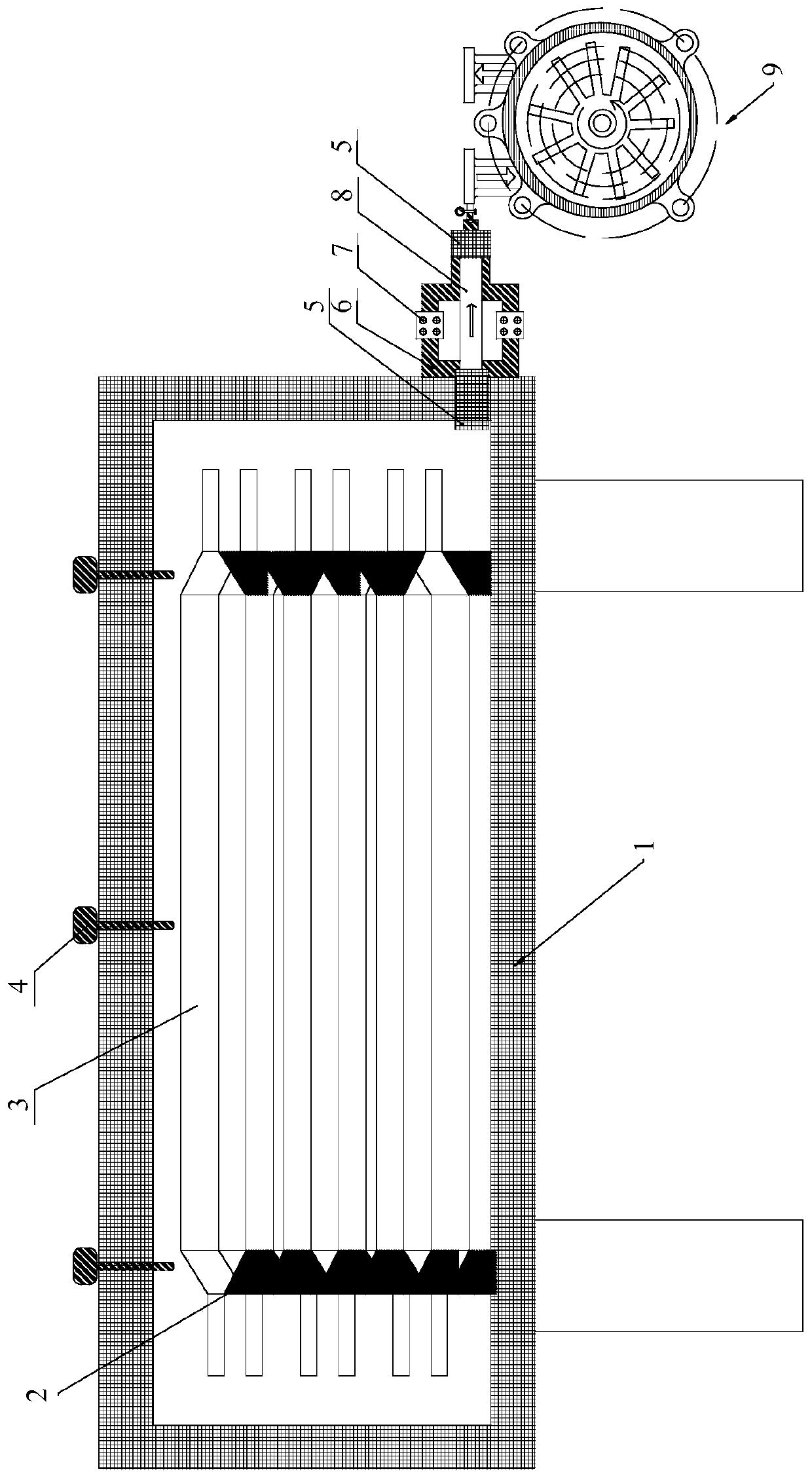

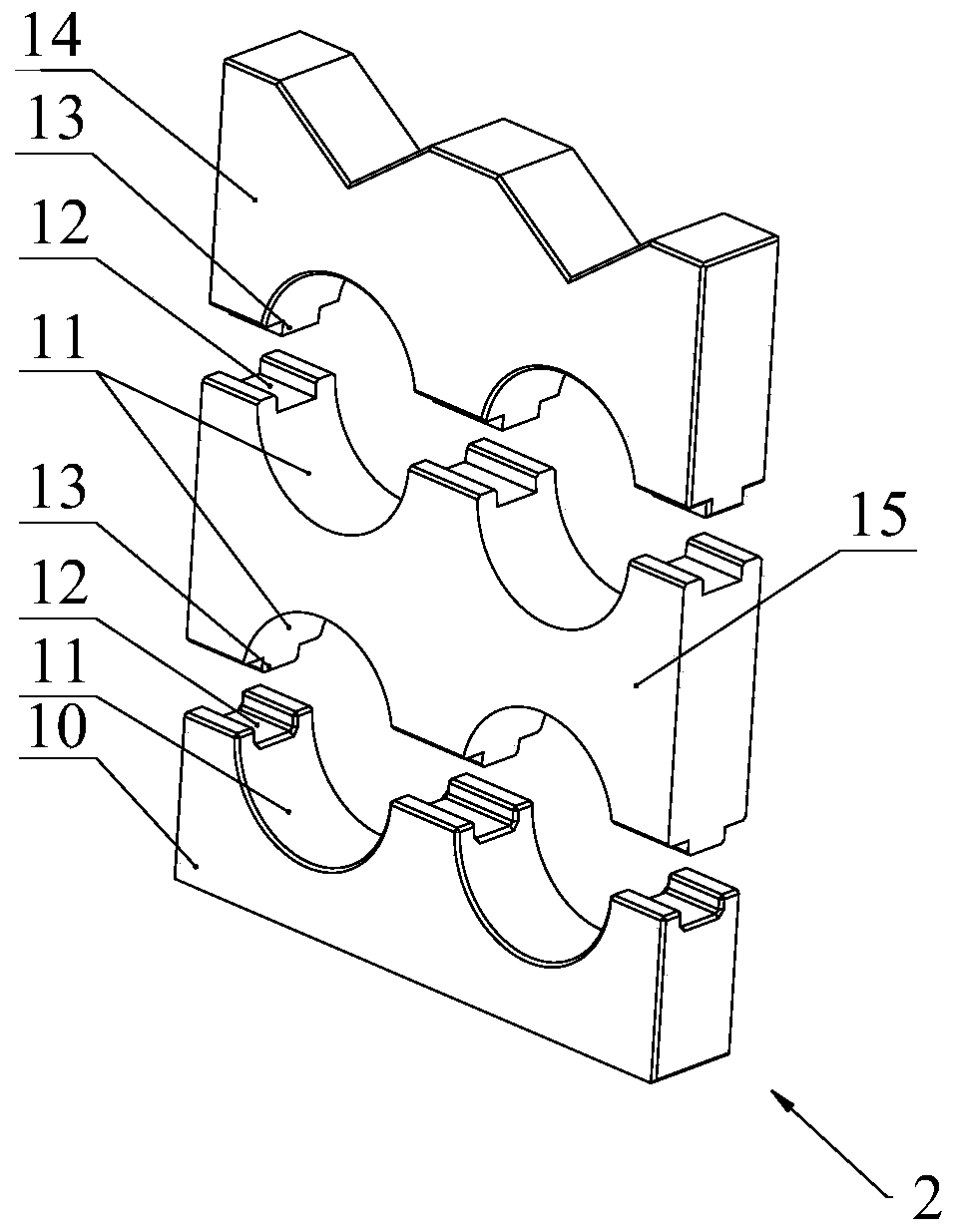

[0049] A dehydroxylation annealing method for a large-size optical fiber preform, referring to figure 1 , including the following steps:

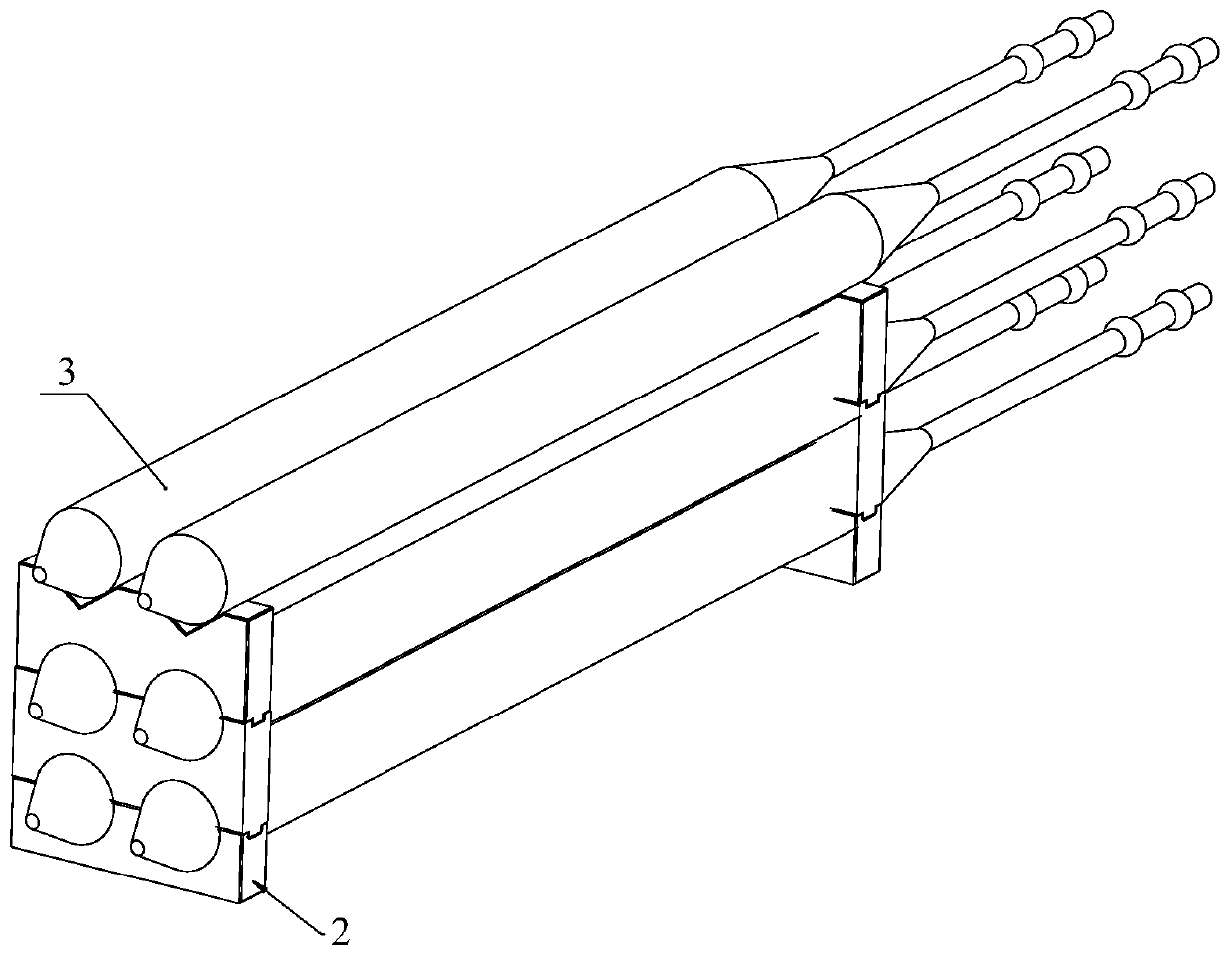

[0050] 1) placing a plurality of optical fiber preforms 3 in the annealing furnace 1, and leaving gaps between the optical fiber preforms 3;

[0051] 2) Heating the optical fiber preform to the stress-relief temperature, the process of heating to the stress-relief temperature includes four stages of uniform temperature rise, and satisfying: the heating rate of the first stage ≥ the heating rate of the second stage ≥ the heating rate of the third stage ≥ The heating rate of the fourth stage;

[0052] 3) Preheating the optical fiber preform 3 with a preset heat preservation time;

[0053] 4) Cooling the optical fiber preform 3 to the preset cooling temperature, cooling to the preset cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com