Dyeing method and Tuscany leather preparation process using the same

A dyeing method and technology for raw leather, applied in the field of Tuscan leather preparation technology, can solve the problems of large difference in the color of the finished rough surface, affecting the dyeing quality of the rough surface and leather board, poor wearing comfort of the finished product, etc. The effect of softening needle hair, improving dye pick-up rate and improving leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

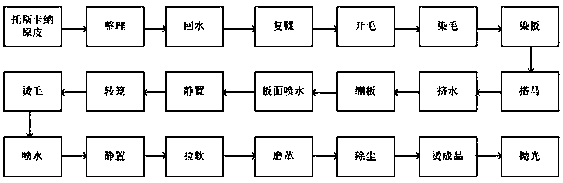

Method used

Image

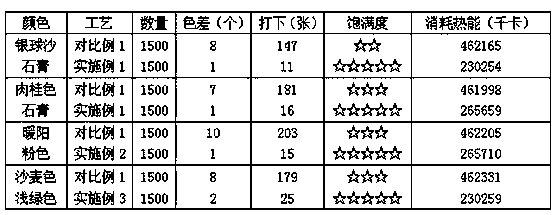

Examples

Embodiment 1

[0034] A dyeing method, comprising the steps of:

[0035] (1) Return water: add water to the drum, add ammonia water, anhydrous sodium sulfate, and fatty aldehyde, and quickly put in the raw Tuscany hide to be dyed after mixing well, rotate for 60 minutes, and stay overnight for 6 hours, with less rotation and more stops. Drain and wash once with cold water; wherein the quality of water added is 1200% of the quality of the original Tuscan hide, the water temperature is 40°C, the quality of ammonia water added is 1% of the quality of the original Tuscan hide, and the quality of adding anhydrous sodium sulfate is 10% of the mass of the original Tuscan hide, and the mass of fatty aldehyde added is 2% of the mass of the original Tuscan hide. The aliphatic aldehyde used in this example is Desoaten DC(N) produced by Sichuan Desaier Chemical Industry Co., Ltd.

[0036](2) Retanning: add water to the drum, do pre-fatliquoring treatment first, add sulfonated oil and general-purpose fa...

Embodiment 2

[0041] A dyeing method, comprising the steps of:

[0042] (1) Return water: add water to the drum, add ammonia water, anhydrous sodium sulfate, and fatty aldehyde, and quickly put in the raw Tuscany hide to be dyed after mixing well, rotate for 60 minutes, and stay overnight for 6 hours, with less rotation and more stops. Drain and wash once with cold water; wherein the quality of water added is 1200% of the quality of the original Tuscan hide, the water temperature is 40°C, the quality of ammonia water added is 1% of the quality of the original Tuscan hide, and the quality of adding anhydrous sodium sulfate is 10% of the mass of the original Tuscan hide, and the mass of fatty aldehyde added is 2% of the mass of the original Tuscan hide.

[0043] (2) Retanning: add water to the drum, do pre-fatliquoring treatment first, add sulfonated oil and general-purpose fatliquor, and rotate for 30 minutes; add formic acid to adjust the pH value to 3.8~4.0, and rotate for 20 minutes; add ...

Embodiment 3

[0048] A dyeing method, comprising the steps of:

[0049] (1) Return water: add water to the drum, add ammonia water, anhydrous sodium sulfate, and fatty aldehyde, and quickly put in the raw Tuscany hide to be dyed after mixing well, rotate for 60 minutes, and stay overnight for 6 hours, with less rotation and more stops. Drain and wash once with cold water; wherein the quality of water added is 1200% of the quality of the original Tuscan hide, the water temperature is 40°C, the quality of ammonia water added is 1% of the quality of the original Tuscan hide, and the quality of adding anhydrous sodium sulfate is 10% of the mass of the original Tuscan hide, and the mass of fatty aldehyde added is 2% of the mass of the original Tuscan hide.

[0050] (2) Retanning: add water to the drum, do pre-fatliquoring treatment first, add sulfonated oil and general-purpose fatliquor, and rotate for 30 minutes; add formic acid to adjust the pH value to 3.8~4.0, and rotate for 20 minutes; add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com