Equipment and method for loading base bleed ignition explosive

A technology of ignition powder and equipment, which is used in offensive equipment, ammunition, weapon accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

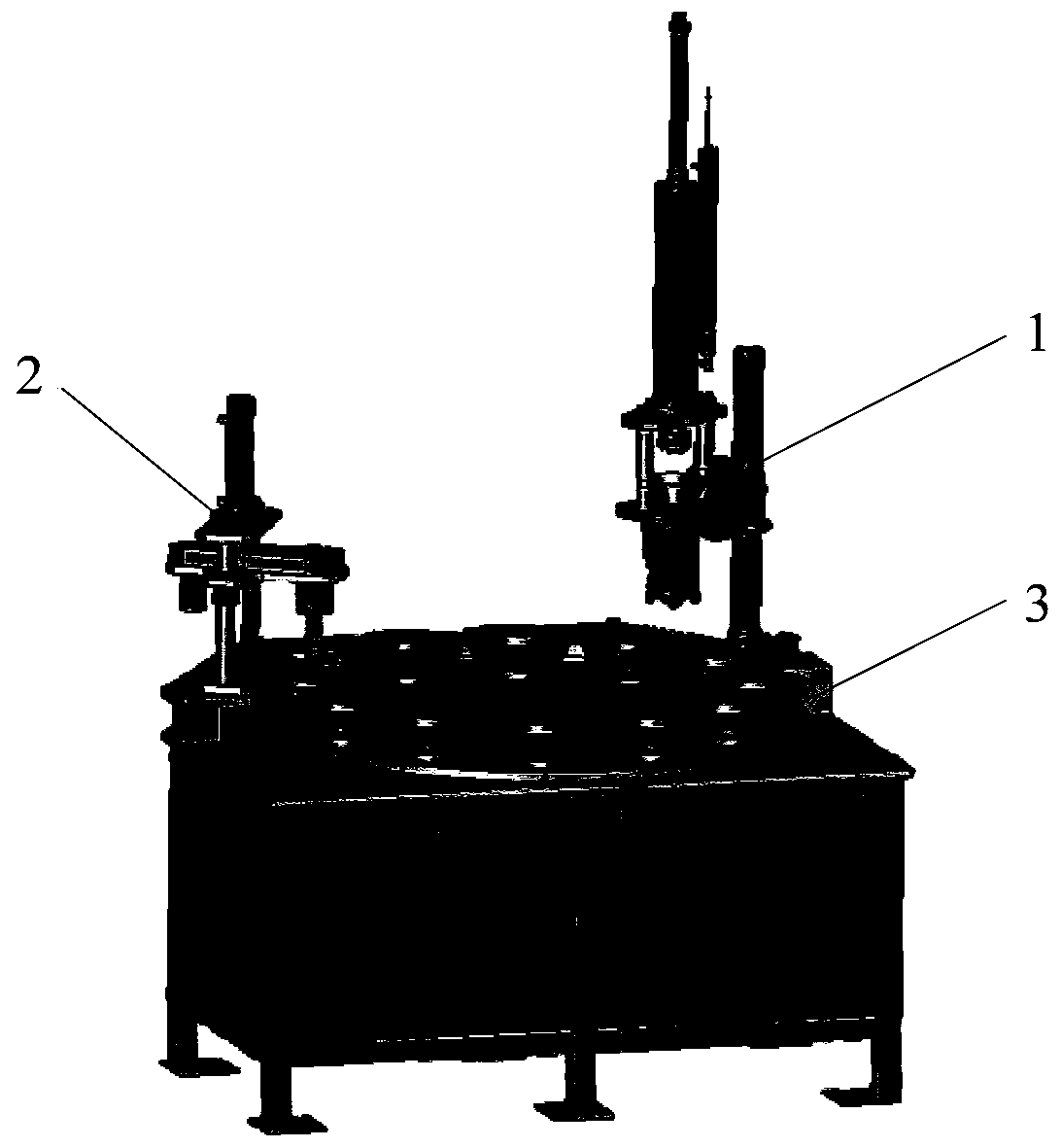

[0037] This embodiment proposes a kind of equipment that is used for the bottom row of igniting powder charge, and its structure is as follows: figure 1 shown. The equipment includes an automatic feeding unit 1 , an automatic paving unit 2 and an automatic transfer unit 3 .

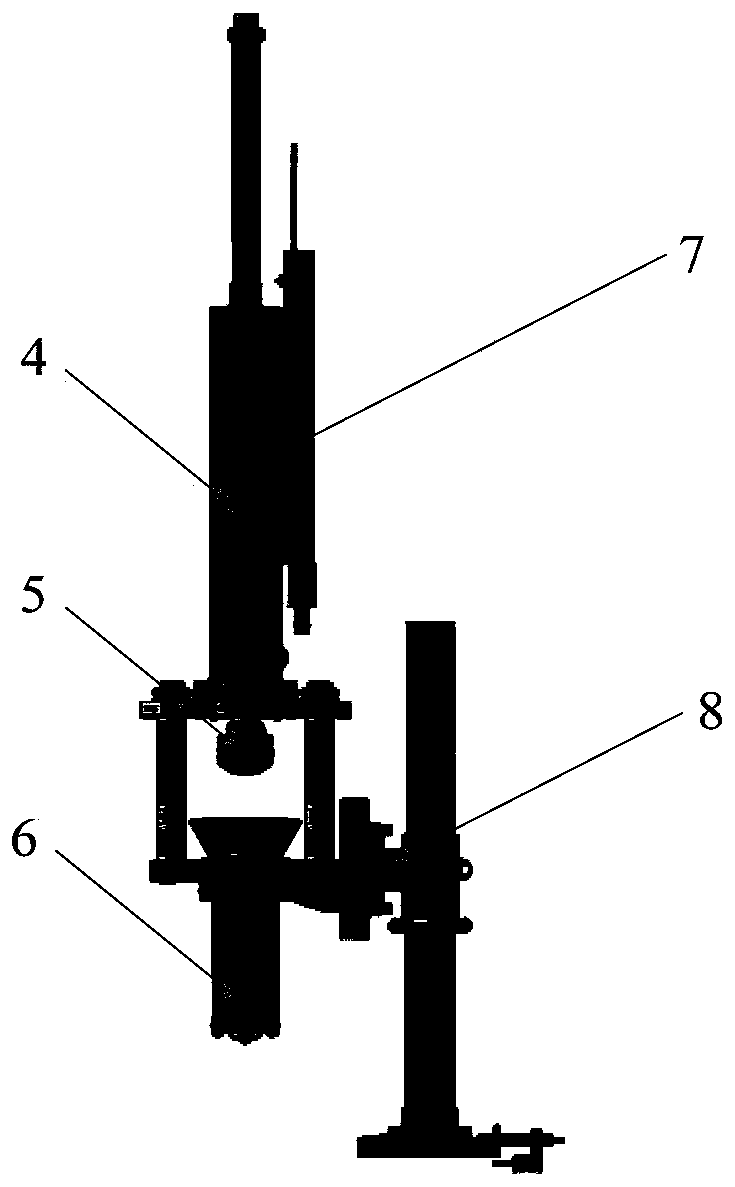

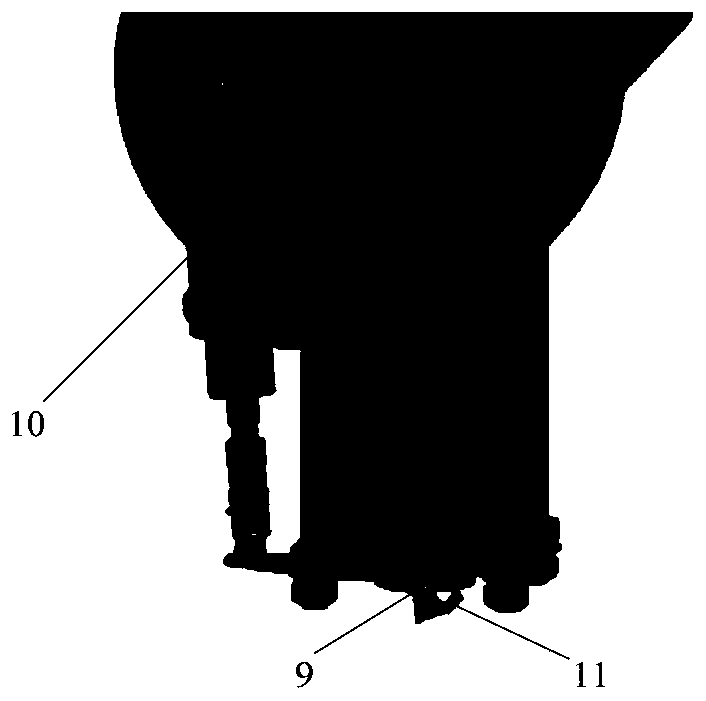

[0038] The automatic feeding unit 1 is used for feeding into the annular groove of the powder column. Such as figure 2 and 3 As shown, the automatic feeding unit 1 mainly includes an extrusion hydraulic cylinder 4, a conical pressure head 5, a material cylinder 6, an electronic ruler 7, a four-way adjustment bracket 8, a medicine flat mouth 9, a medicine bar cutting cylinder 10 and a lever-shaped cutting machine. plate 11.

[0039] Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com