Transverse vibration test device for fastener

A technology of lateral vibration and test device, applied in vibration test, measurement device, test of machine/structural components, etc., can solve the problems of single test effect, inability to adjust test temperature, etc., to improve reliability, reduce shaking amplitude, realize The effect of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

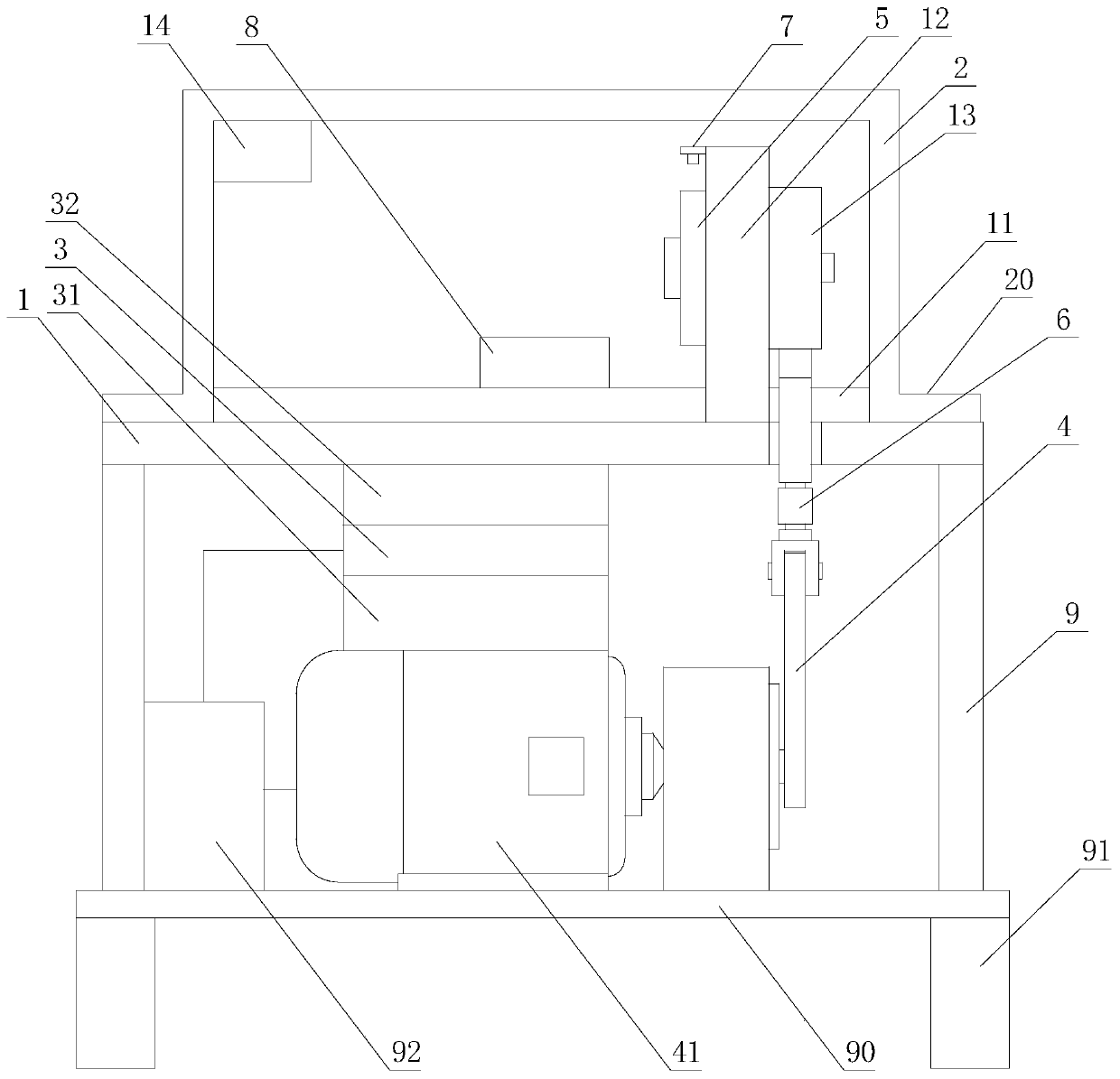

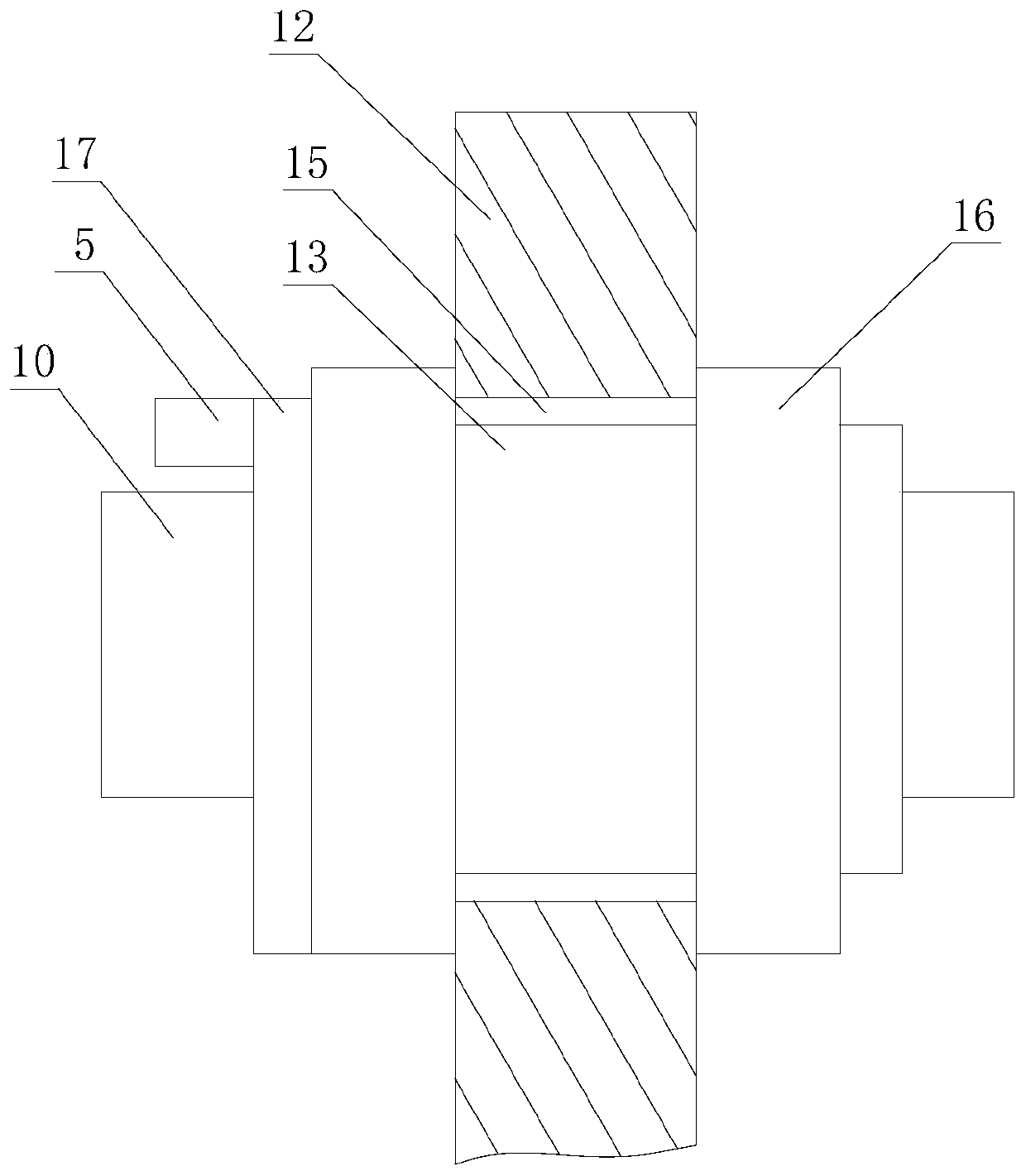

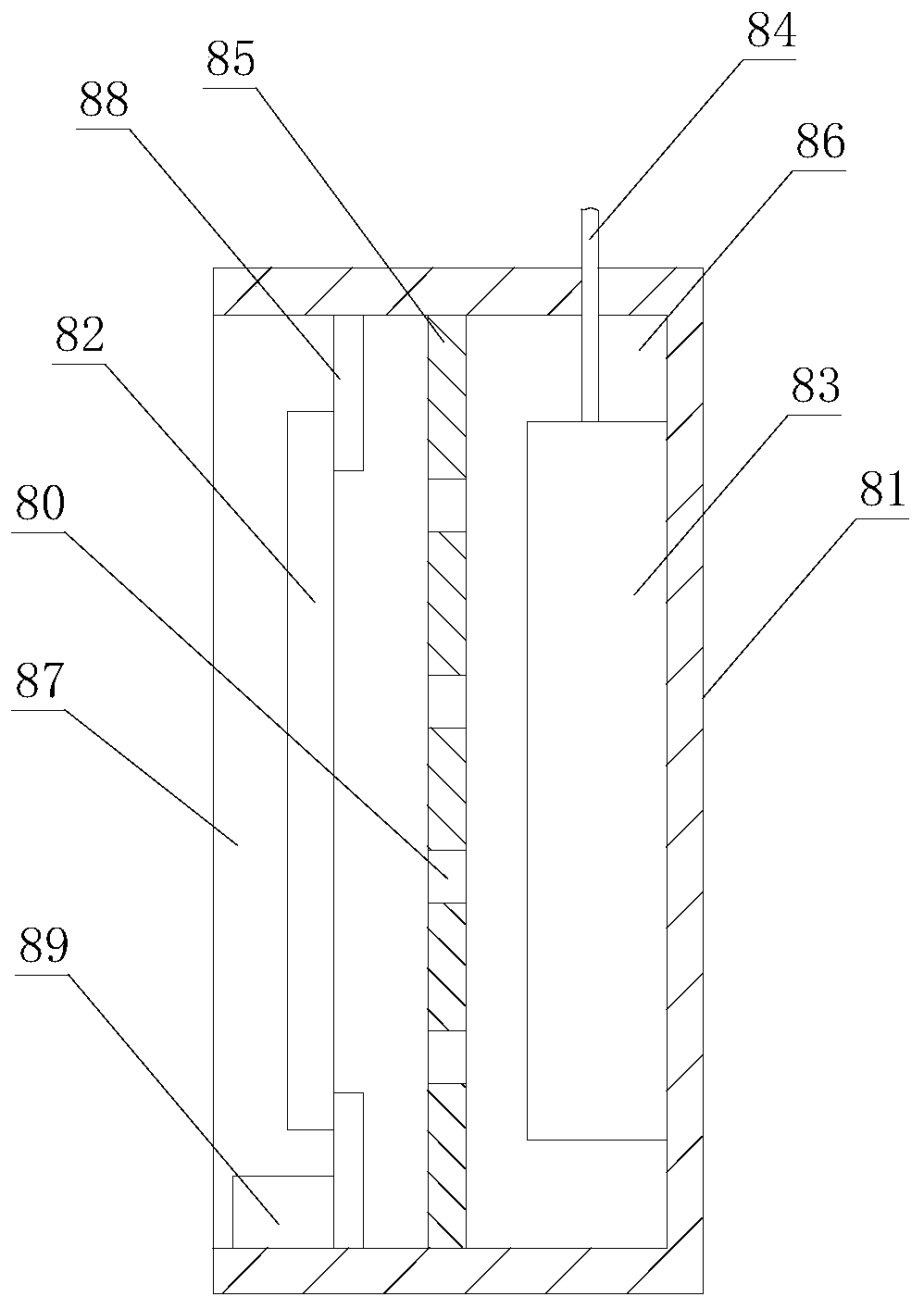

[0031] like figure 1 , figure 2 , image 3 As shown, a fastener lateral vibration test device includes a mounting table 1, a sealing cover 2 and a semiconductor cooling chip 3, the mounting table includes a vertical plate 12 extending upward, and a horizontal mounting sleeve is provided on the vertical plate 12 13. The fastener 10 to be tested is installed on the vertical plate 12 through the horizontal installation sleeve 13. The installation table 1 is provided with a drive assembly that drives the horizontal installation sleeve 13 to reciprocate up and down on the vertical plate 12. The horizontal installation The sleeve 13 is provided with a first load cell 5 for measuring the axial pretightening force of the fastener, and the crank mechanism is provided with a second load cell 6 for detecting the lateral pretightening force of the fastener under test. The vertical plate 12 is provided with a displacement sensor 7 that detects the lateral displacement of the fastener un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com