A method for fault diagnosis and location of robot rv reducer

A technology of fault diagnosis and positioning method, applied in the direction of neural learning method, machine/structural component testing, instrument, etc., can solve the problems that restrict the development of acoustic emission detection, affect the development of acoustic emission detection technology, and the signal characteristics are not obvious, etc., to achieve The effect of preventing mechanical equipment failure and accuracy decline, avoiding comprehensive economic losses, and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the examples.

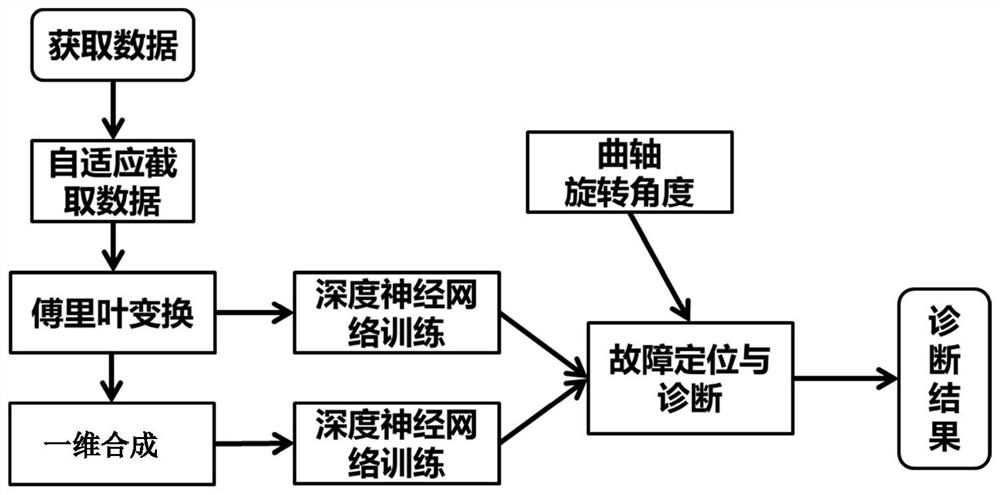

[0039] The adaptive wear degree detection method of acoustic emission signal based on deep neural network combines acoustic emission detection with deep learning, and uses the unsupervised learning characteristics of deep learning to split the acoustic emission signal with a large amount of data into several combinable The signal fragments, and then use these fragments for training to obtain a deep learning network, and finally realize the rapid detection of the wear degree of the RV reducer, which provides a better solution for engineering applications.

[0040] The invention provides a method for measuring the wear degree of an adaptive robot RV reducer based on a deep neural network and an acoustic emission signal, comprising steps:

[0041] A. Collect acoustic emission signals;

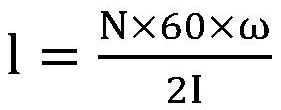

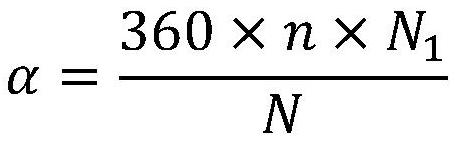

[0042] B. Adaptively split the collected acoustic emission signals under different worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com