High-performance mobile gas intake unit for gas engine

A technology of air intake device and gas engine, which is applied in the direction of measurement device, internal combustion engine test, engine test, etc. It can solve the problems of long disassembly and installation process, affecting detection efficiency, and complicated connection, so as to improve the sealing performance and facilitate disassembly and assembly , to avoid the effect of shaking

Inactive Publication Date: 2019-11-01

江苏华强新能源科技有限公司

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] But on the one hand, this kind of air intake device can only be used fixedly, and the flexibility is relatively poor; It needs to be installed and fixed between tests to avoid shaking during the test. At the same time, the connection of the filter element needs to be sealed. The current sealing method is to fix the sealing plate with screws. The overall connection is more complicated, and the disassembly and installation process is relatively complicated. Long, affecting the overall detection efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

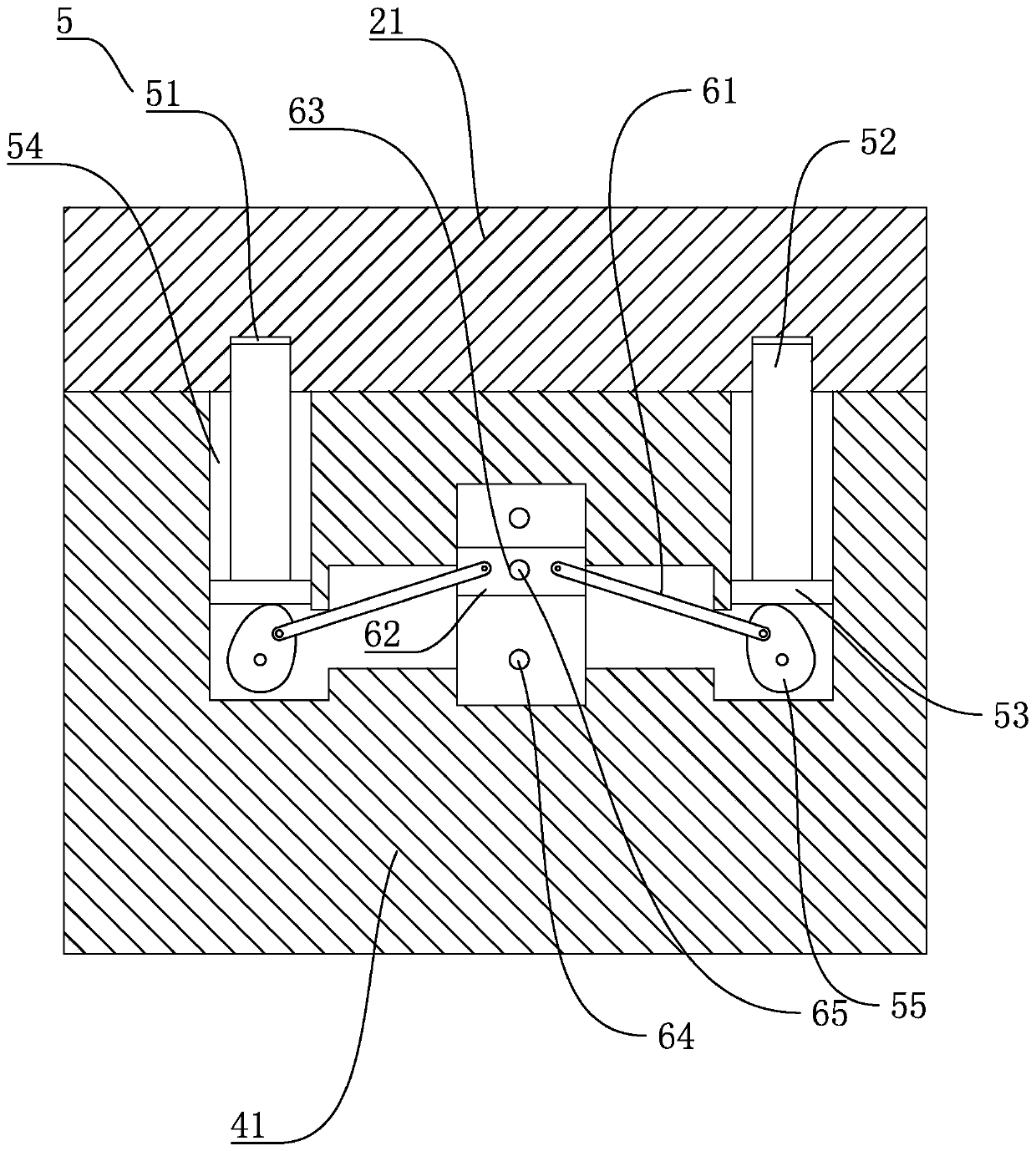

[0035] A high-performance gas engine mobile air intake device provided in this embodiment, such as Figure 4 As shown, the difference from Embodiment 1 is that the mounting plate 41 is provided with a driving motor 66 provided with a vertical driving block 62, and the output shaft of the driving motor 66 is provided with a driving screw 67, and the driving screw 67 penetrates and drives The block 62 is screwed with the drive block 62 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

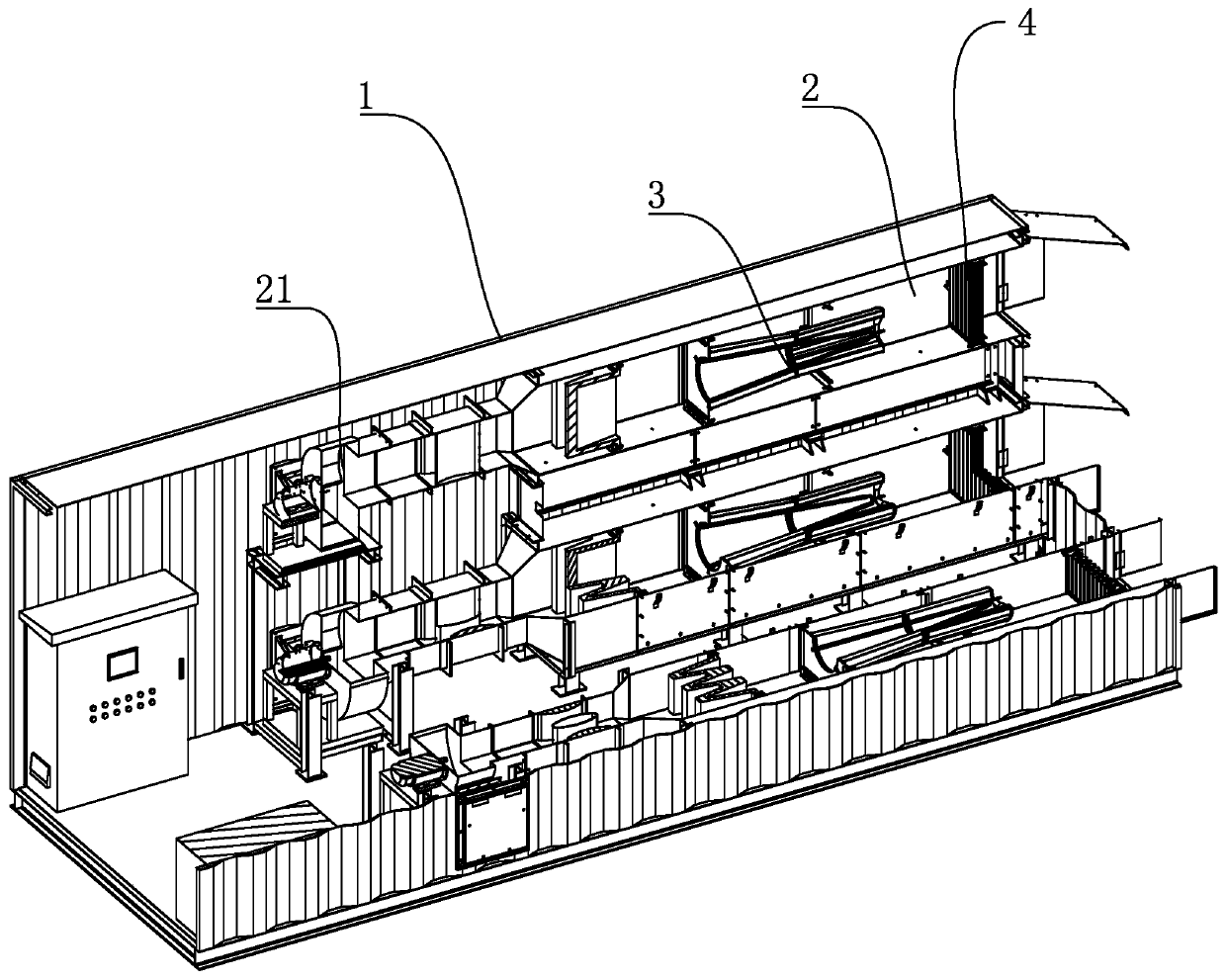

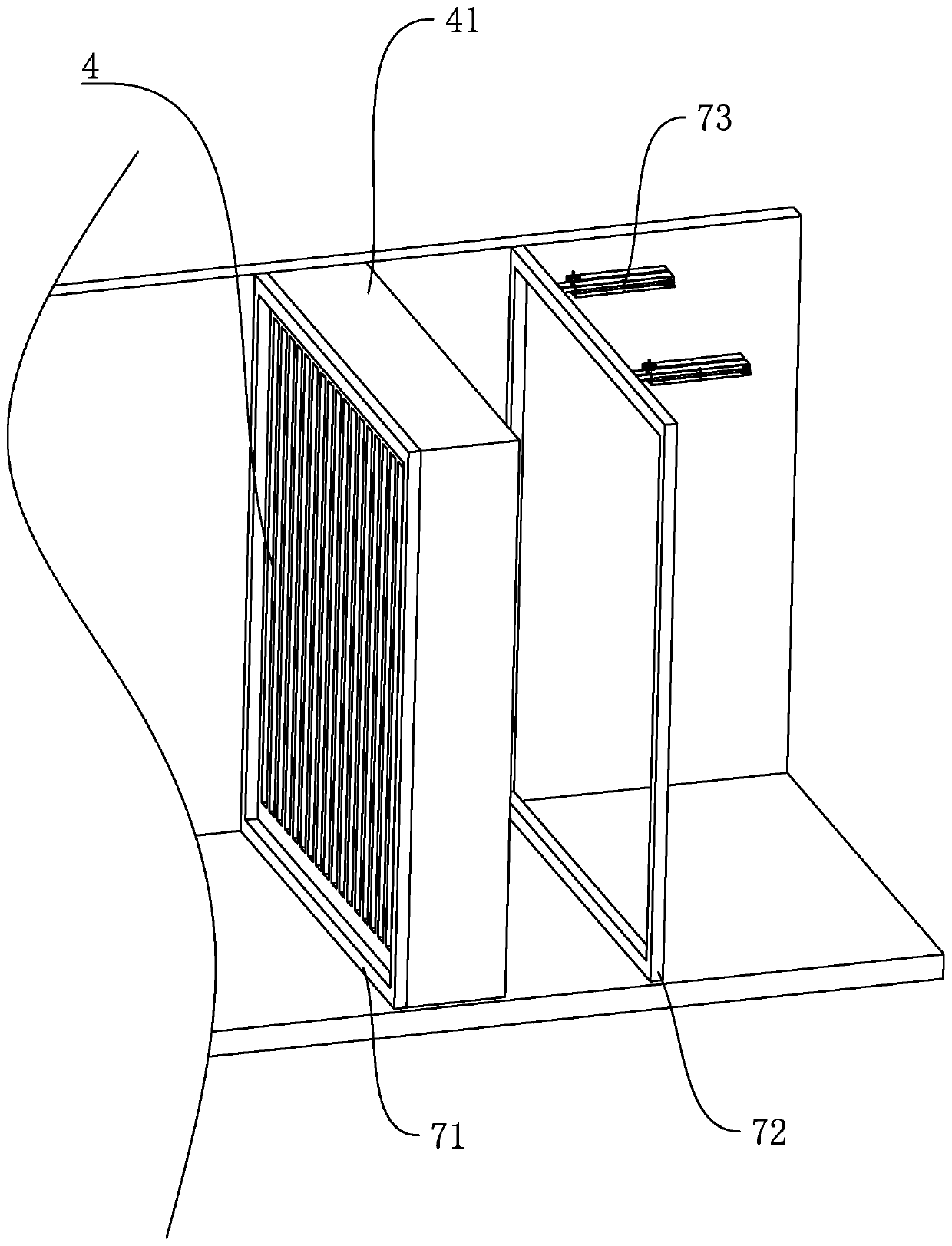

The invention discloses a high-performance mobile gas intake unit for a gas engine, and relates to the technical field of filter element production equipment. The high-performance mobile gas intake unit comprises a test container, wherein a test channel for installing a filter element is fixed in the test container, a blower is fixed at one end of the test channel, the other end is provided with the filter element to be tested, a gas generator is arranged between the blower and the filter element to be tested, the gas outlet of the gas generator faces the filter element to be tested, a mounting plate integrally connected to the filter element is arranged around the filter element to be tested, a connecting mechanism for fixing the two is provided between the mounting plate and the test channel, and the test channel is further provided with a sealing member. The mobile filter element testing device is relatively simple in installation and disassembly structures, can relatively conveniently realize the installation and disassembly of the filter element and avoid affecting the detection efficiency of the filter element, thereby achieving better use effect, having good overall sealingproperty and stable fixing at the same time, and avoiding the shaking caused by the force during the test.

Description

technical field [0001] The invention relates to the technical field of filter element production equipment, in particular to a mobile air intake device for a high-performance gas engine. Background technique [0002] The gas engine generates power and work by burning natural gas or artificial gas, which can be used to drive cars and ships and drive generators to generate electricity. The advantage is that it is cleaner and more environmentally friendly than diesel or gasoline engines. It can replace diesel engines and gasoline engines, and is now widely used in public transportation, oil field power generation and other fields. [0003] The gas engine can automatically adjust the amount of air injection to adapt to changes in the environment, so that the gas engine can maintain a full combustion state for a long time in different time periods, different gas source environments, and when adjusting the size of the fire. The function of the gas engine to adjust the gas volume...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): G01M15/02G01M15/04

CPCG01M15/02G01M15/04

Inventor 解波唐敏冷盼马永

Owner 江苏华强新能源科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap