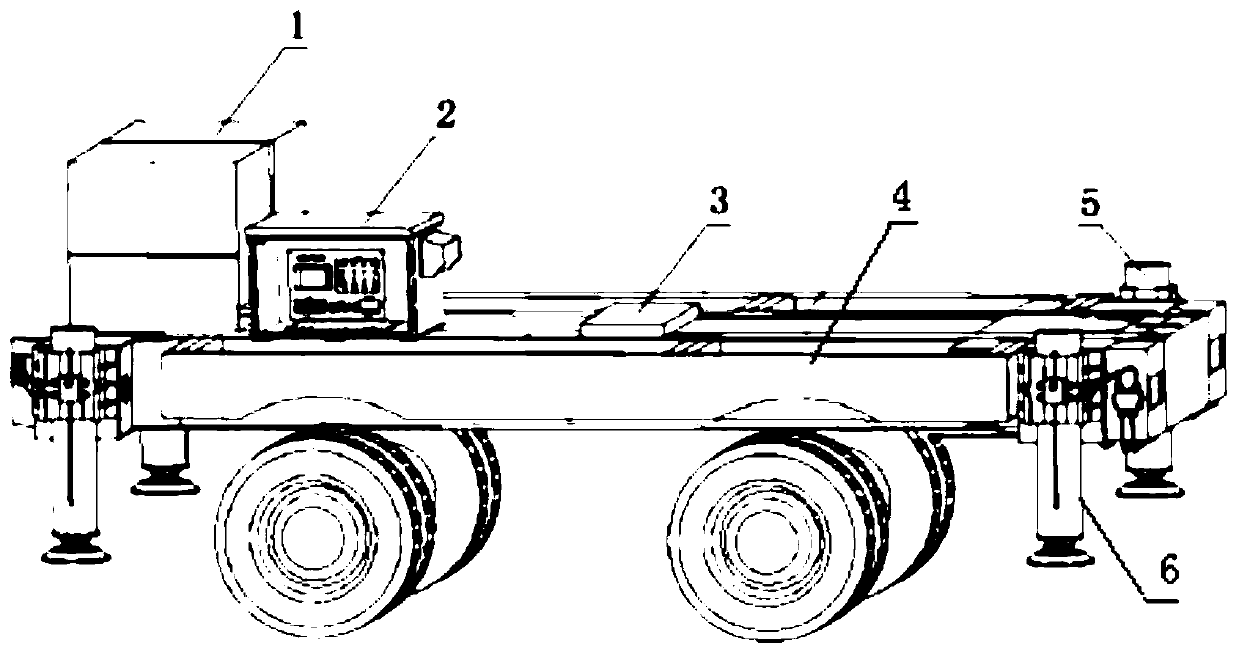

Modeling method of aerial work platform base plate automatic levelling system

An aerial work platform and system modeling technology, applied in the field of autonomous leveling system modeling of aerial work platform chassis, can solve the problems of low leveling accuracy and lack of modeling analysis, so as to simplify the complexity, improve leveling accuracy and The effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

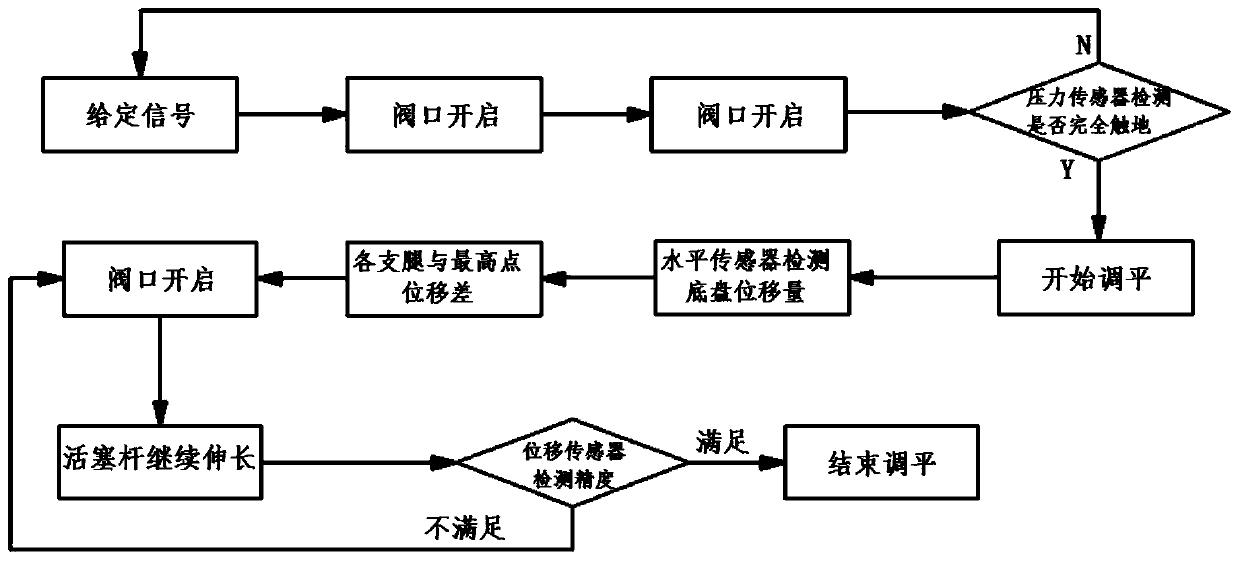

[0033] When the aerial work platform starts to work, in order to achieve chassis leveling, it is divided into three stages:

[0034] In the first stage, after the aerial work platform arrives at the designated work place, the four outriggers are extended synchronously. After the first outrigger touches the ground, in order to overcome the soft and uneven ground, a pressure sensor is installed to detect whether the virtual space of the telescopic cylinder is solved. Leg problem, the remaining three legs touch the ground in turn, repeat the above;

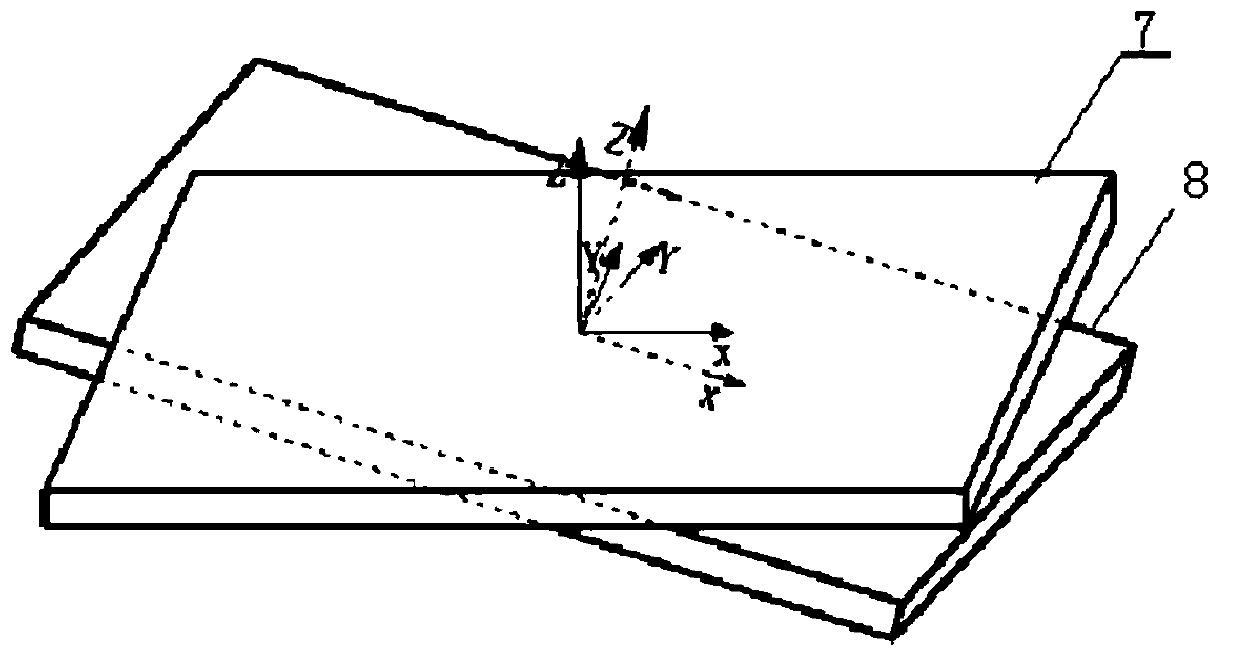

[0035] In the second stage, after each outrigger is completely in contact with the ground, the displacement difference between each point of the chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com