Machining error statistical analysis device

A statistical analysis and machining technology, applied in computing, manufacturing computing systems, instruments, etc., can solve the problems of large part size data, many calculation formulas, and heavy measurement workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

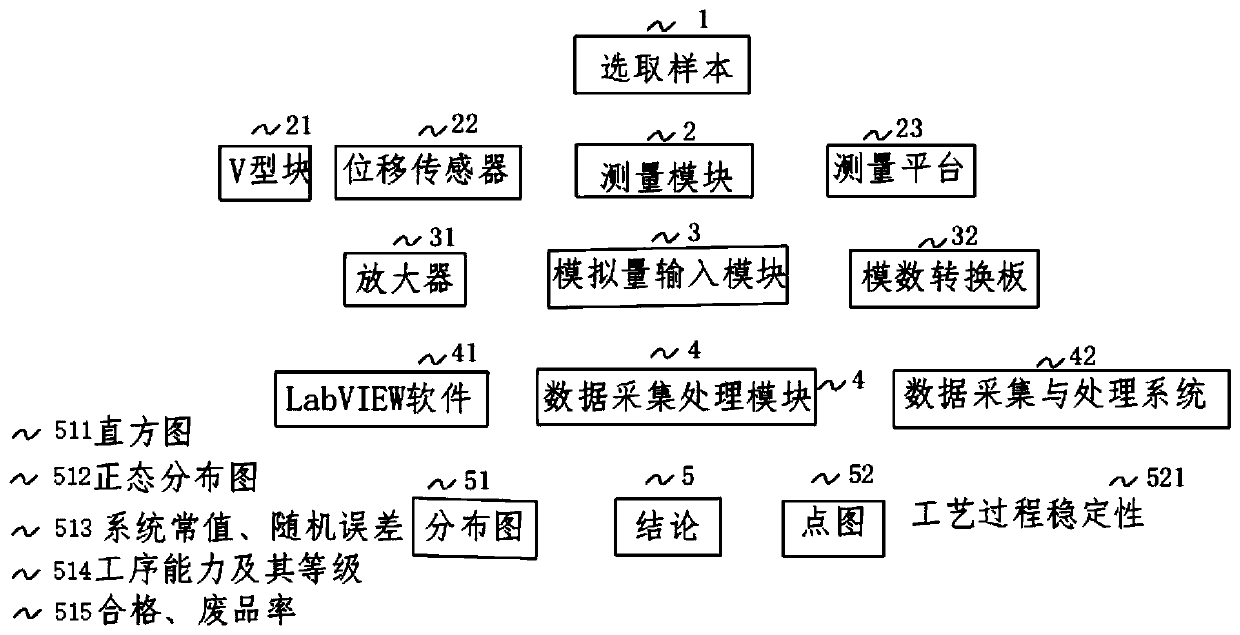

[0030] The machining error statistical analysis method of the present invention is as figure 1 shown, including the following steps:

[0031] 1. Sample size measurement

[0032] Select the sample capacity n (usually n=50-200 pieces); use high-precision digital calipers to measure the size of the first position of the sample part, and use the measuring platform and V-shaped block to measure the displacement fixed on the beam of the measuring platform The sensor is zeroed; the beam and longitudinal beam of the measuring platform can be adjusted in the horizontal and vertical directions according to the measurement requirements. The size error of the position), the original size of the first position, that is, the reading of the high-precision digital caliper plus the sum of the displayed data value of the displacement sensor.

[0033] 2. Analog input module

[0034] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com