Method for improving uniformity of plating surface of PCB pattern

A graphic electroplating and copper plating technology, applied in electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of laser holes that cannot be filled, insufficient contact, uneven substrate plating thickness, etc., and achieve reasonable additive composition and concentration. , Increase the exchange capacity, avoid the effect of rough copper plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

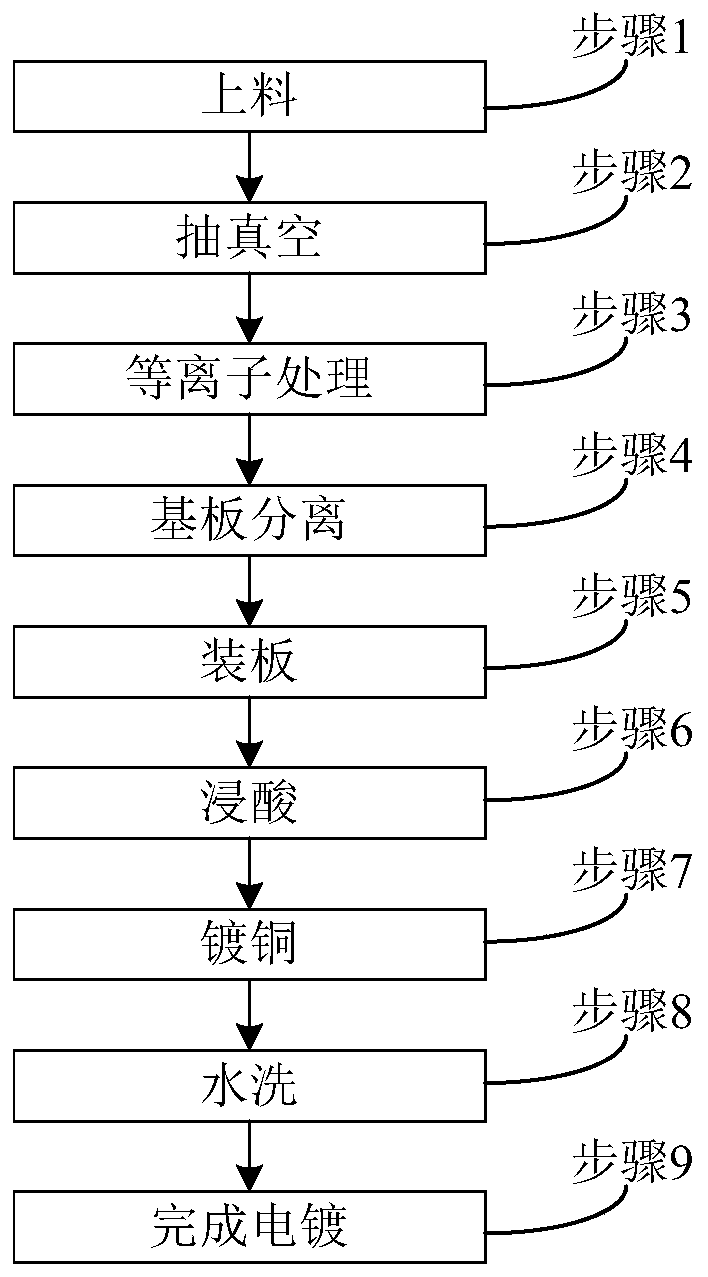

[0044] Such as figure 1 As shown, a method for improving the uniformity of PCB pattern plating surface described in the embodiment of the present invention mainly includes the steps of feeding, vacuuming, plasma treatment, substrate separation, board loading, pickling, copper plating, and water washing. .

[0045] The specific flow of each step will be described in detail below.

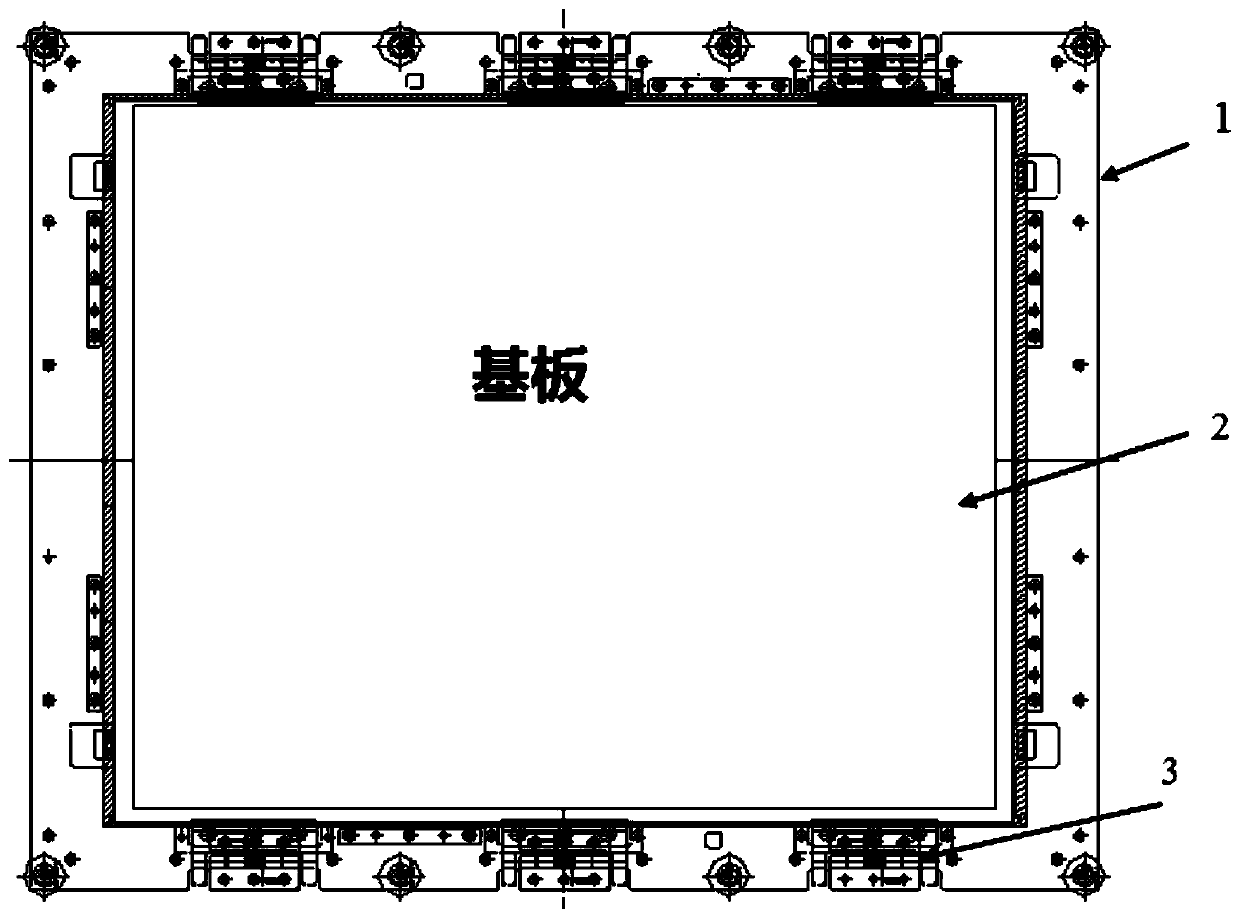

[0046] Step 1, loading: put the developed PCB substrate 2 into the jig 1, and transfer the jig 1 to the pre-processing device.

[0047] Such as figure 2 As shown, the jig 1 is a return-shaped structure, the PCB substrate 2 is placed in the middle of the jig 1, and the two opposite edges inside the jig 1 are respectively provided with a plurality of clamping devices 3, and the two edges of the PCB substrate 2 pass through A plurality of clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com