Oat peeling machine

A technology of peeling machine and oats, which is applied in grain husking, grain processing, application, etc. It can solve the problems of incomplete separation of oats and oat bran, difficult to shoot out, waste of oats, etc., to avoid oat residues, prevent waste, The effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments.

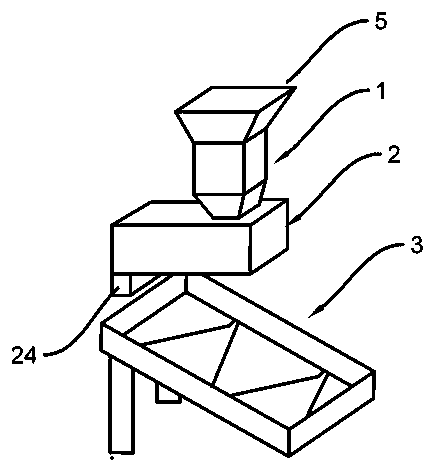

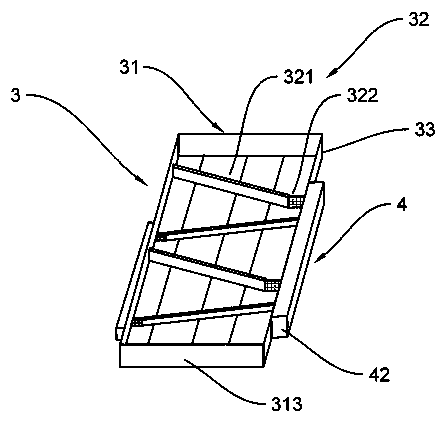

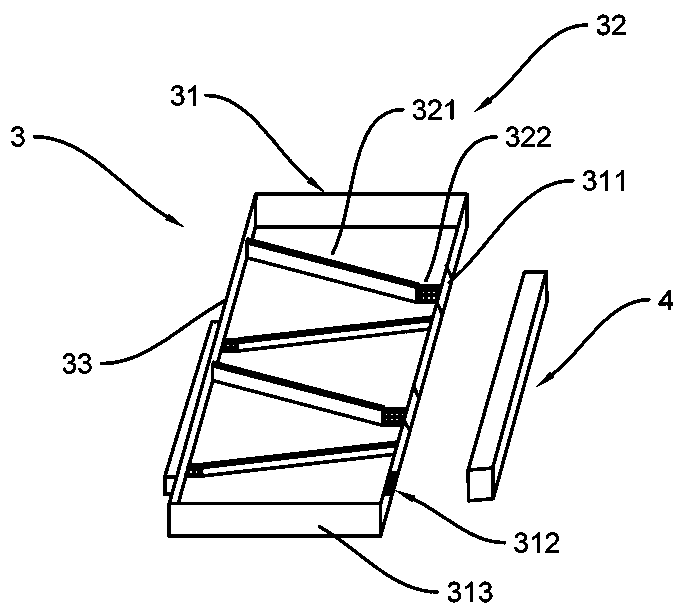

[0030] see Figure 1 to Figure 7 , an oat peeling machine, comprising a first peeling chamber 1, a second peeling chamber 2 communicated with the first peeling chamber 1, a roller device 11 is arranged in the first peeling chamber 1, and the roller device includes two The rotating roller 111 that is arranged in parallel, is affixed to described first peeling chamber 1 inner wall and is arranged on the fixed roller 112 in the middle of two rotating rollers 111, and a rotating cross bar 21 is set in the described second peeling chamber 2, and described rotating horizontal bar A propeller blade 22 and a stirring rod 23 are fixedly installed on the rod 21, and the second peeling chamber 2 includes a discharge port 24, and also includes a leather separator 3 arranged directly below the discharge port 24, and the leather material The separator 3 includes a vibrating screen 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com