Circular saw

The technology of a circular saw and a rotor is applied to a circular saw. It can solve the problems of anti-blocking ability of electric tools and the difficulty of user experience to meet the needs, so as to achieve the effect of optimal control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

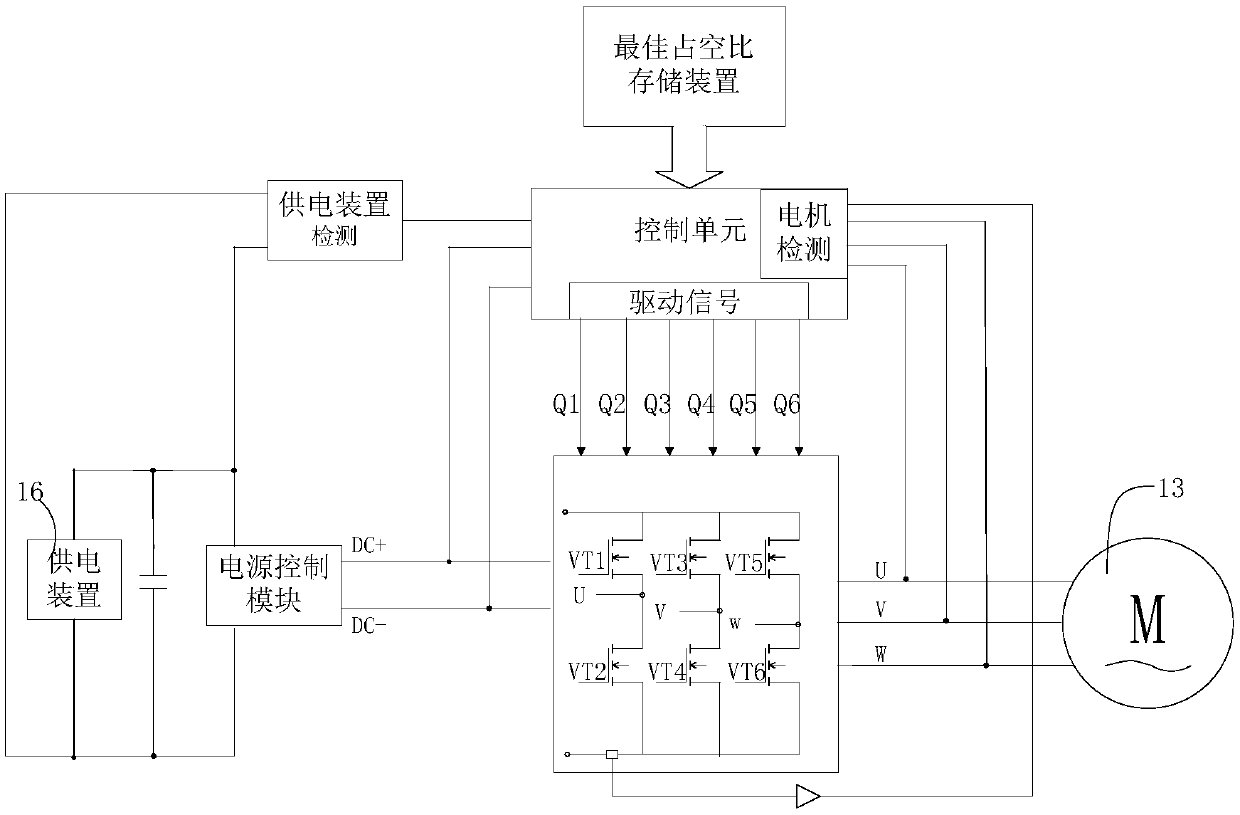

[0036] The motor control method and system provided by the present invention can be applied to most hand-held electric tools. It is only necessary to obtain the duty cycle corresponding to different working conditions based on the analysis of the characteristic parameter V of the power supply device and / or the characteristic parameter x of the motor. The duty cycle corresponding to x is used to control the driving circuit to drive the motor to operate, so as to realize the maximum inrush current of the electric tool and the optimization of the maximum output torque of the electric tool.

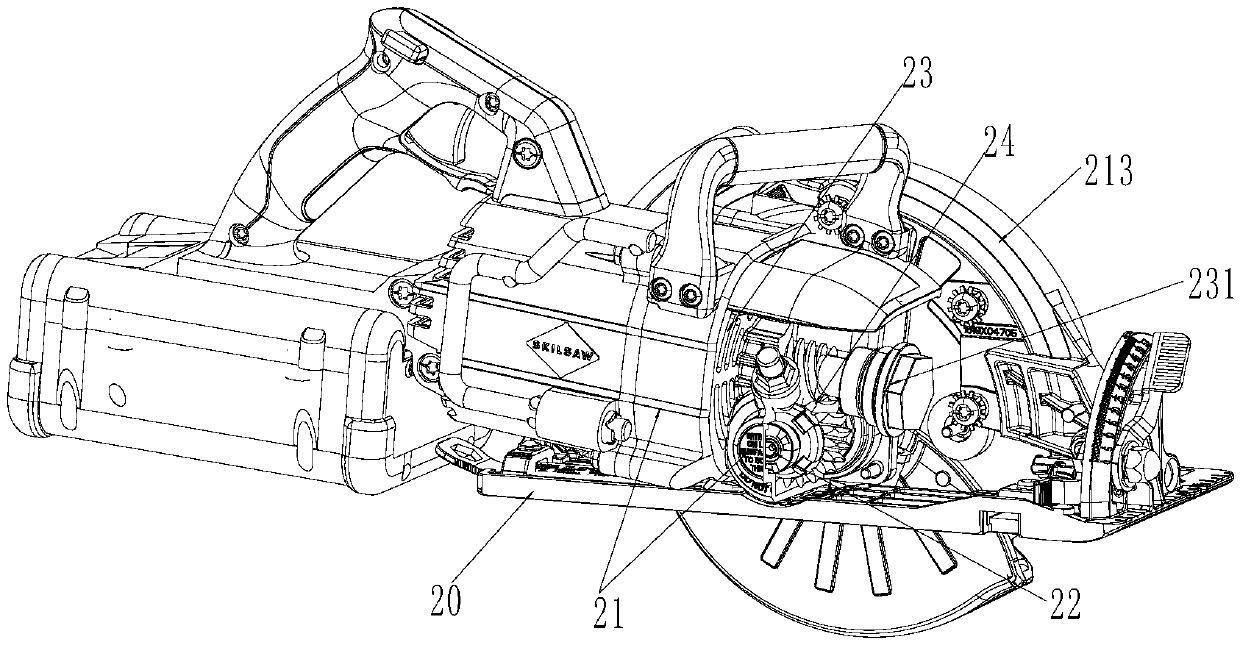

[0037] The specific embodiments of the present invention will be described below by taking three typical electric tools as examples.

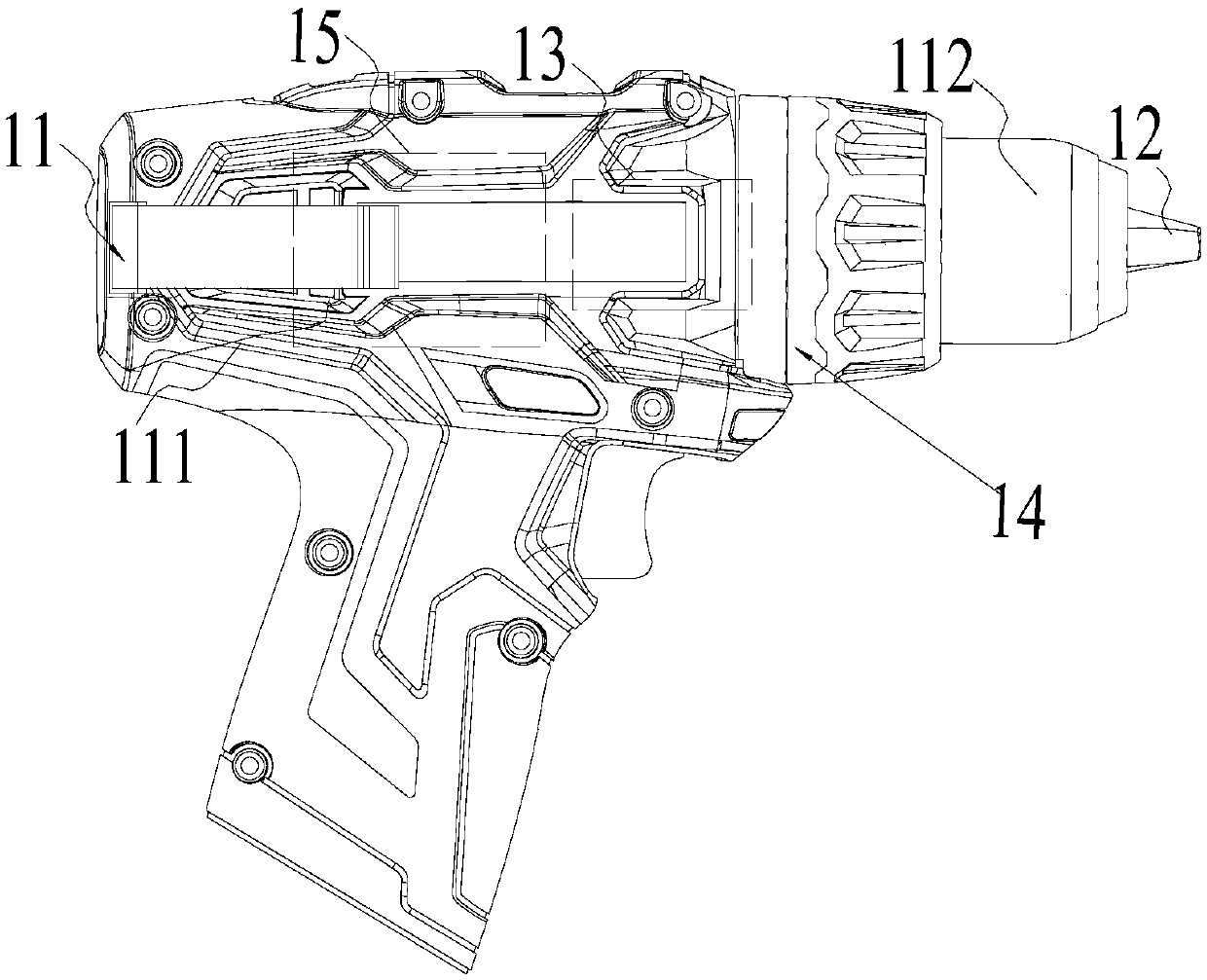

[0038] In the first embodiment of the present invention, combining figure 1 The mechanical structure of the provided el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com