Operation method of autoclaved aerated concrete reinforcement panel saddle conveying device

A technology of autoclaved gas filling and conveying device, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of equipment damage, affecting the work progress, time-consuming and laborious, etc., and achieve the effect of reducing loss and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

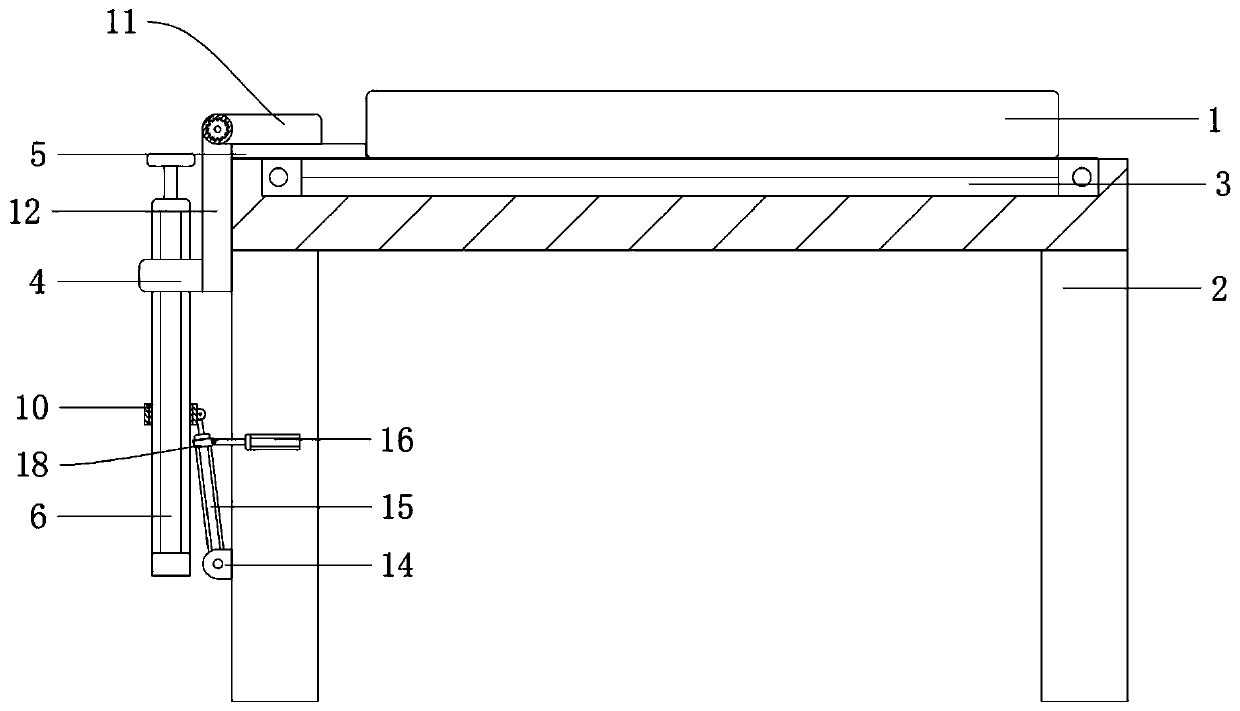

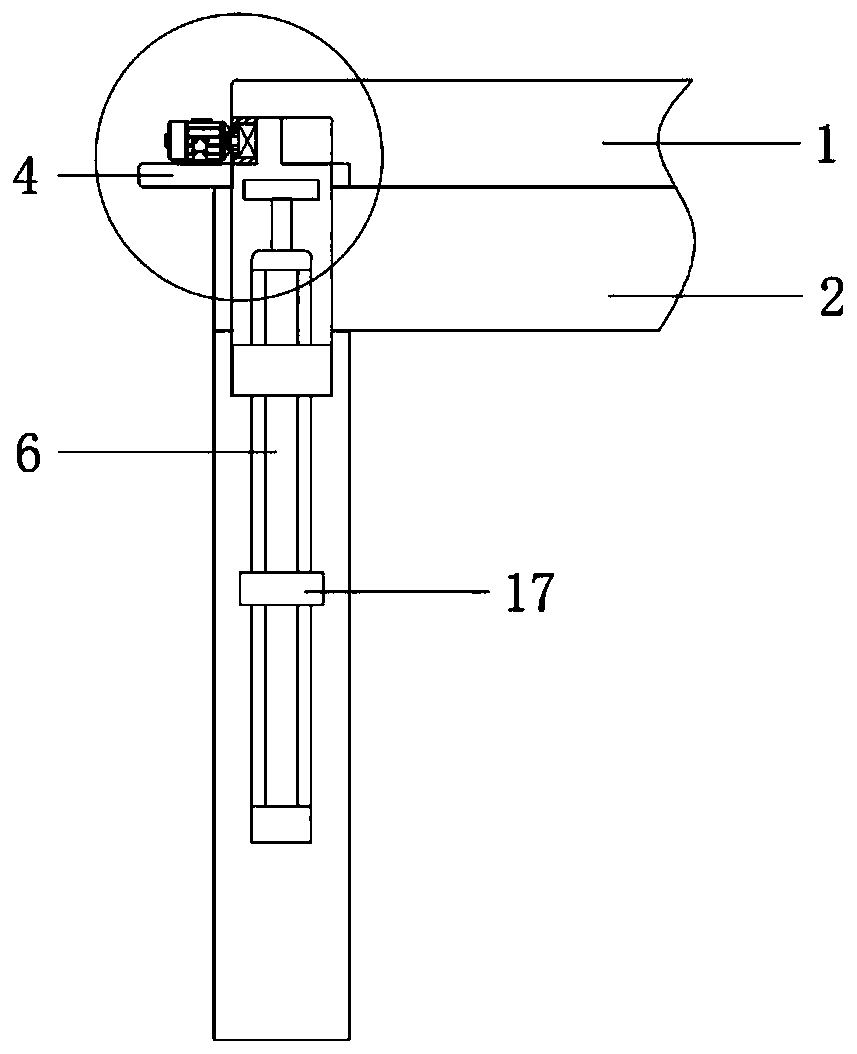

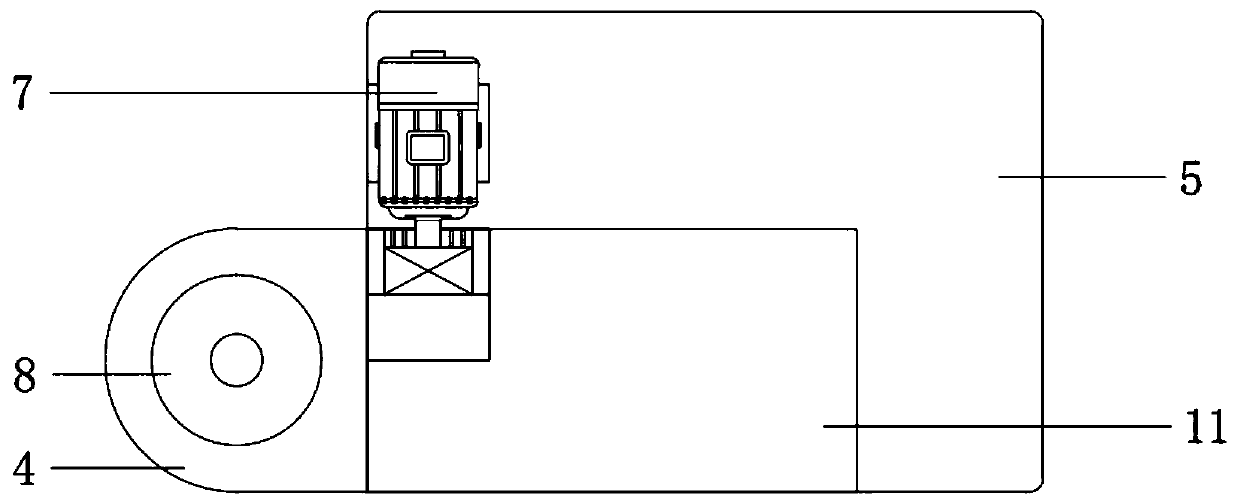

[0024] Embodiment 1: The present invention provides a kind of technical scheme: According to the description attached Figure 1-4 It can be seen that this case is an operation method for the saddle frame conveying device for autoclaved aerated concrete reinforced slabs, which mainly includes: frame 1, moving frame 2, screw module 3, connecting block 4, connecting plate 5, hydraulic rod 6, The driving machine 7, the electromagnet 8, the driving end gear 9 and the movable components are connected as follows:

[0025] The screw module 3 is embedded on the moving frame 2, one end of the frame 1 is installed on the screw module 3, the connecting plate 5 is installed on the screw module 3, one end of the movable component is installed on the connecting plate 5, and the connecting block 4 Installed on the other end of the movable assembly, one end of the hydraulic rod 6 is installed on the connecting block 4, the driving machine 7 is installed on the connecting plate 5, the driving e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap