Pit bottom reservoir stage construction method based on internal drainage strip mine middle bridge

A technology for open-pit mines and reservoirs, applied in excavation, bridges, construction, etc., can solve the problems of waste of intermediate bridge space, high difficulty, and large water storage requirements, and achieve the effect of reducing water evaporation and construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

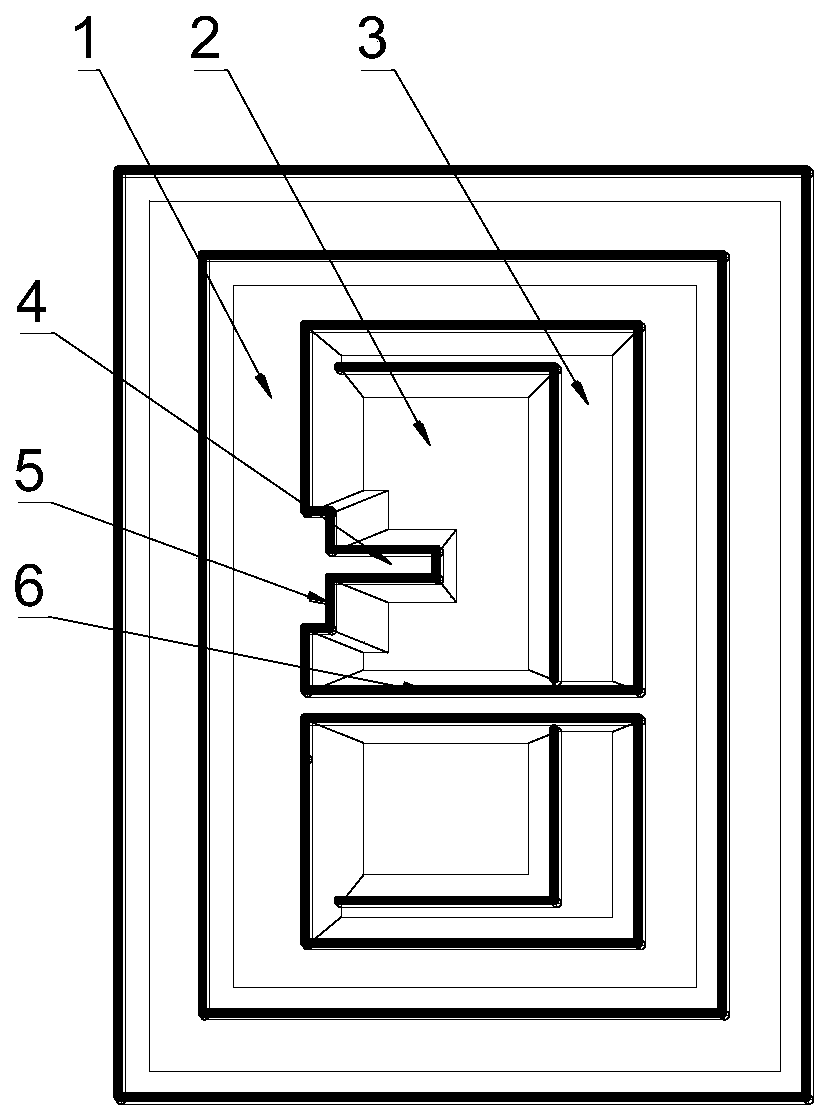

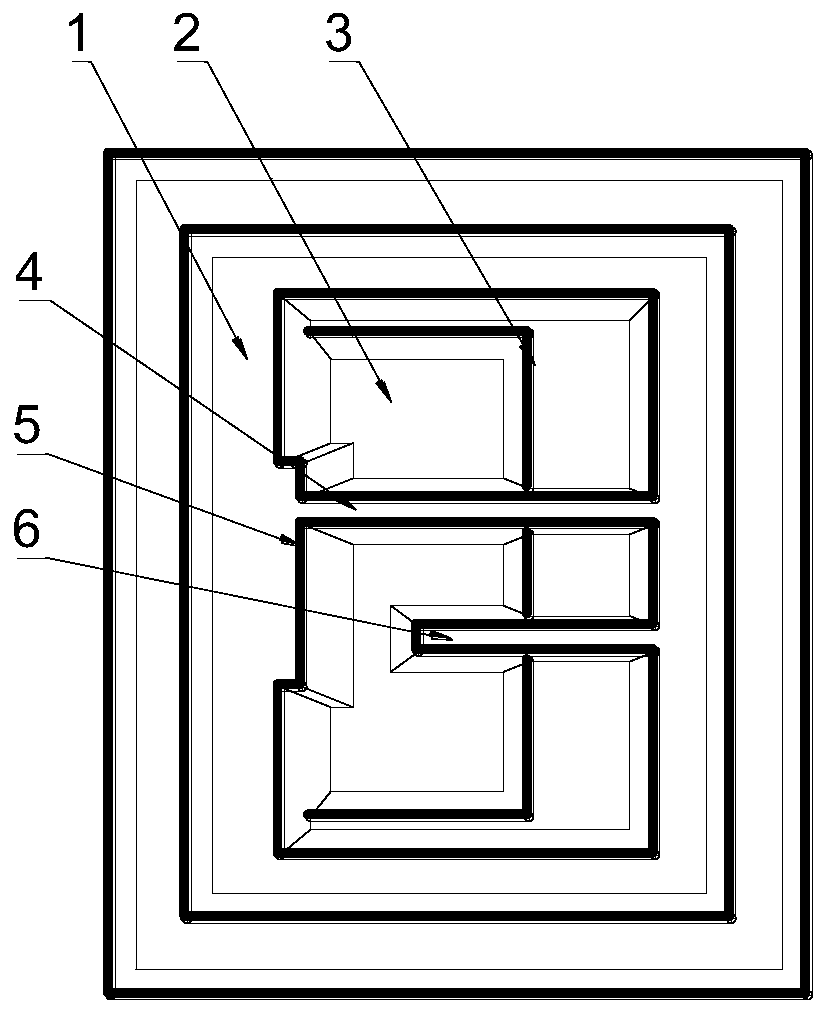

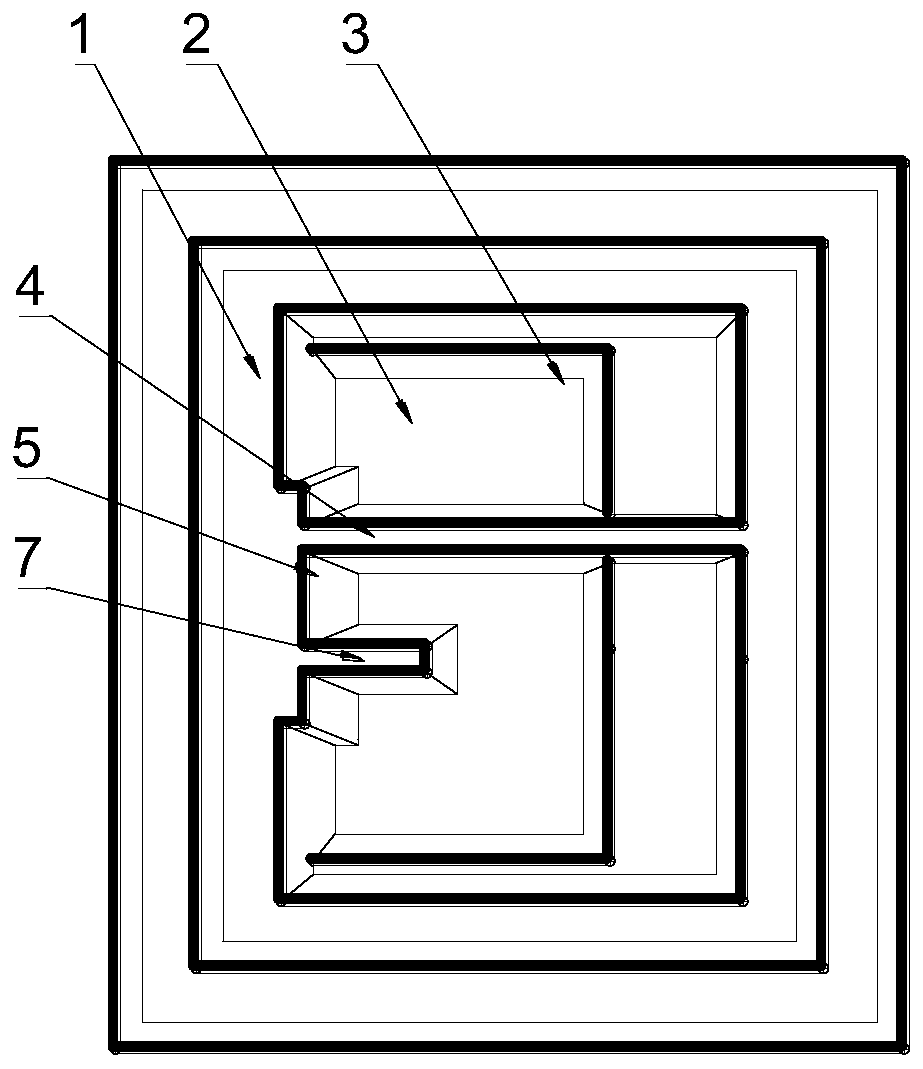

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] like figure 1 , 2 As shown in , 3, a phased construction method of the pit bottom reservoir based on the middle bridge of the inner row open-pit mine is divided into the first phase of reservoir construction, the later phase of reservoir construction and water resource storage, wherein the first phase of reservoir construction steps are as follows:

[0034] S1: Construction of dump site 1 in stope 3. When the lowest working line of dump site 1 in the open-pit mine is 20-30m away from the coal-rock interface of Zhongzhong Bridge, the bottom step of dump site 1 discharges clay and discharges The range is 0-200m inside the middle bridge, and the inside is the position between the current middle bridge 6 and the second middle bridge to be arranged in the future. After the water wall 5 is formed, the bottom step of the dump site 1 in the open-pit mine sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com