Water-sand backfilling construction platform of pipeline in municipal road limited space and method thereof

A technology for limited space and municipal roads, which is applied in the field of pipeline water shake sand backfill construction platform under the limited space of municipal roads, can solve the problems of large construction space, difficult construction of large machinery, troubles, etc., to improve efficiency, facilitate construction, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

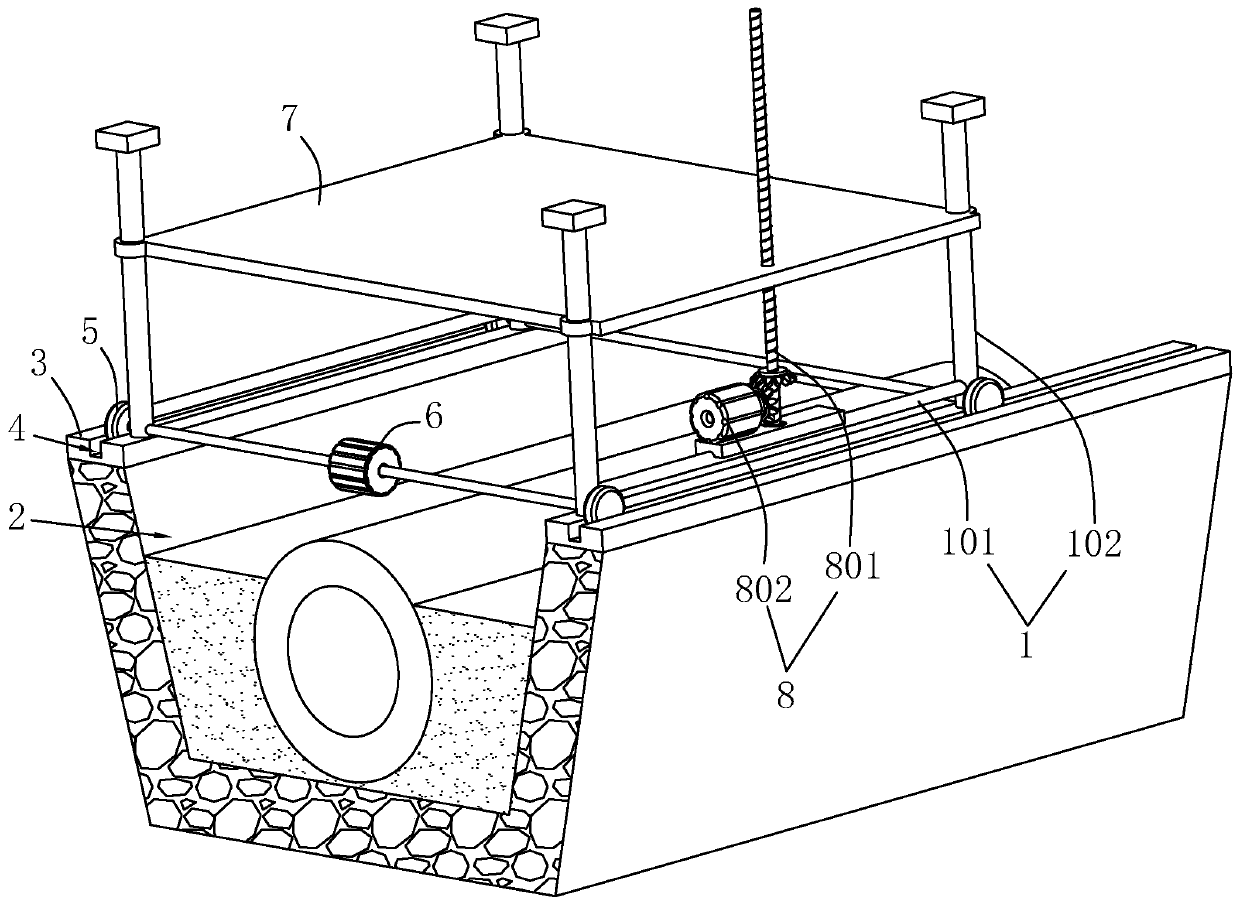

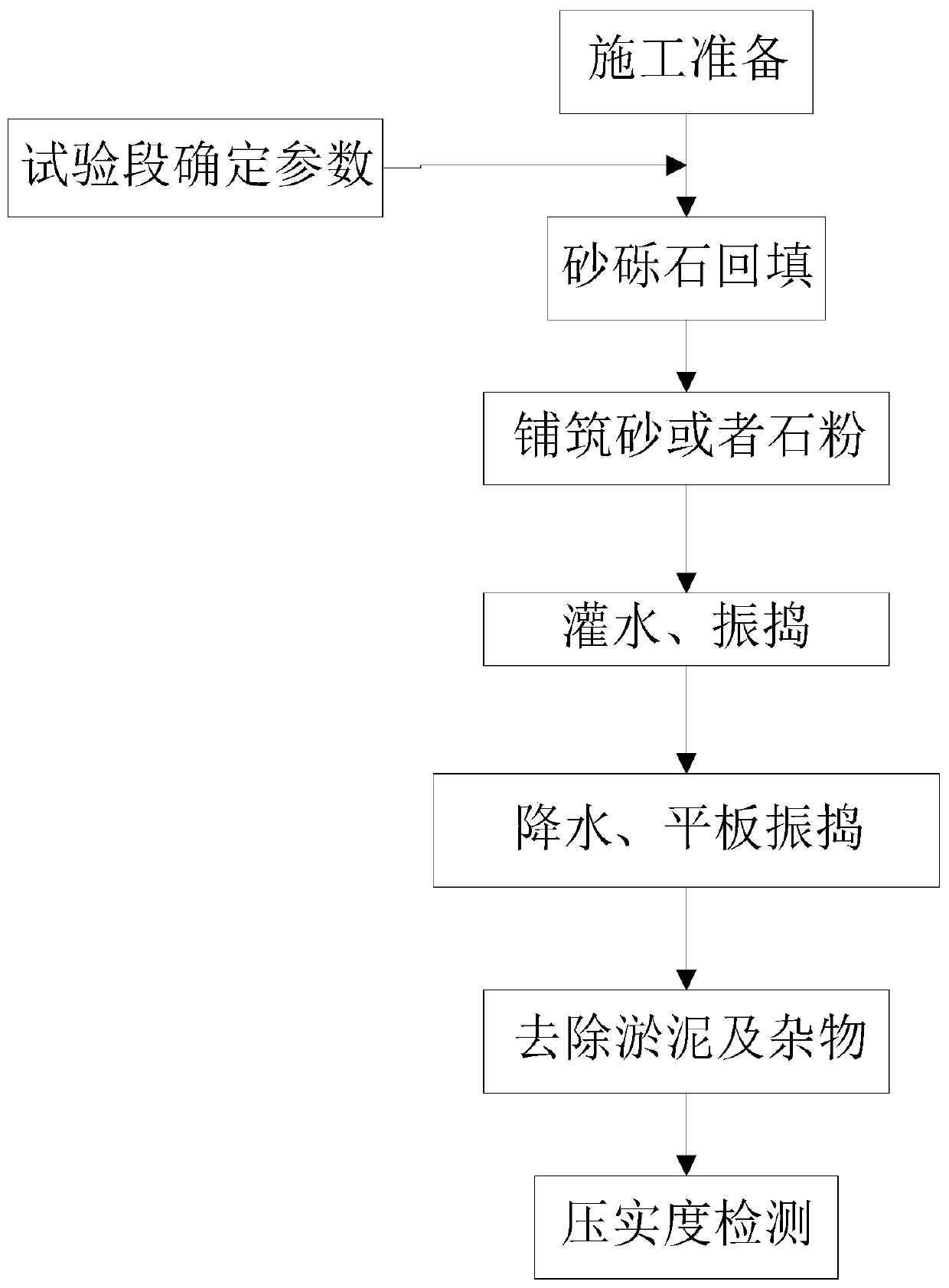

[0036] Such as figure 1 As shown, this embodiment discloses a pipeline water-shaking sand backfilling construction platform in the confined space of municipal roads, including a frame 1 and guide rails 3 arranged along the length direction of the trench 2 and on both sides thereof. The guide rail 3 is provided with a chute 4 along its length direction. The guide rail 3 is made of multiple sections connected by bolts, and the guide rail 3 is fixed on the foundation on both sides of the groove 2 by bolts or bolts. The bottom of the frame 1 rotates with rollers 5 for cooperating with the chute 4 , and the frame 1 is provided with a first motor 6 for driving the rollers 5 to rotate. The frame 1 includes four cross bars 101 and four vertical bars 102, the four cross bars 101 are connected end to end and welded to form a rectangle, and each vertical bar 102 is vertical and fixedly welded to the right angle of the four cross bars 101 connected to form a rectangle. A construction pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com