Bundle penetrating device for interior of post-tensioning method prestress corrugated pipe and construction method thereof

A corrugated pipe and prestressing technology, which is applied in the post-tensioned prestressed corrugated pipe inner beam threader and its construction field, can solve the changes in the metal structure of steel strands, the unfavorable mechanical properties of steel strands, and the difficulty in threading beams one by one. problems, to achieve the effect of saving maintenance costs, avoiding loss of mechanical properties, and avoiding bellows damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

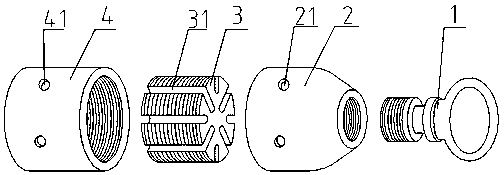

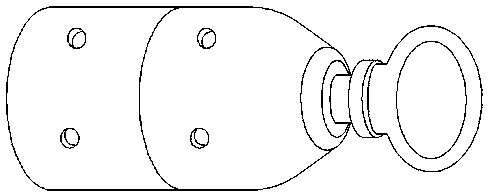

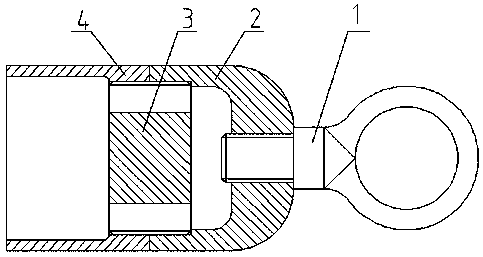

[0039] Post-tensioned prestressed corrugated tube inner beam threader, the end of the steel strand 5 is fixed on the wire hanging plate 3 in the middle, the rear of the wire hanging plate 3 is connected with the restraint ring 4, and the front of the wire hanging plate 3 is connected with the traction head 2 , the pull ring 1 is arranged at the front end of the traction head 2;

[0040] Several gaps 31 are set on the wire hanging plate 3, the gaps 31 run through the length direction of the wire hanging plate 3, and the width of the gap 31 is 6mm, which can block the thick part of the end pier of the steel strand 5, and the diameter of the steel strand 15.24mm;

[0041] The outer circumference of the thread hanging plate 3 is provided with external threads, which match the threads of the inner circle of the restraint circle 1; the restraint circle 1 is provided with a clamping hole A41;

[0042] The outer circumference of the thread hanging plate 3 is provided with external th...

Embodiment 2

[0057] The difference from Example 1 is that: the end of the rod of the pull ring 4 is provided with a mushroom head, and the mushroom head is located in the pull head 2, the rod diameter of the pull ring 1 is smaller than the rod hole of the pull head 2, and the pull ring 1 can be opposite to the pull head 2. Free rotation; the front end of the traction head 2 is conical.

Embodiment 3

[0059] The difference from Embodiment 1 is that the notches 31 are arranged in parallel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com