A method for controlling the transformation of crystal form ii to crystal form i by adding liquid additives that can be matched to the melt processing of isotactic poly-1-butene

A liquid additive, melt processing technology, applied in the field of matching iP-1-B melt processing process, can solve the problems of mechanical property loss, matching, product size and performance instability, etc., to avoid mechanical property loss, avoid inventory placement, achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments.

[0028] Use Basel's sample PB0400# to prepare sample pieces: melt and press the sample PB0400# at 150-180 degrees Celsius to obtain PB0400# (Basel) sample pieces with a diameter of 12mm and a thickness of 18μm, 20μm and 40μm , choose to press tablet at 5MPa for 2min.

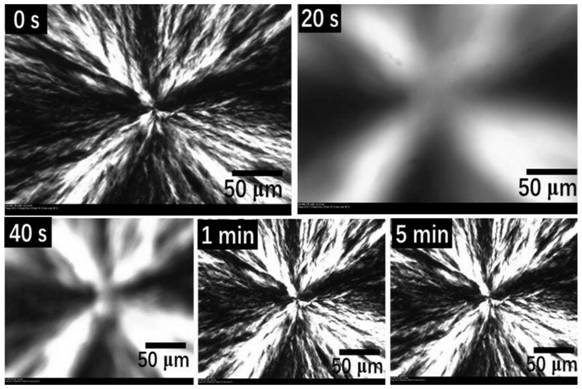

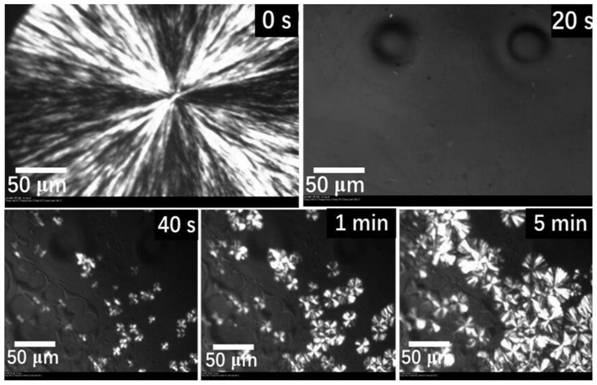

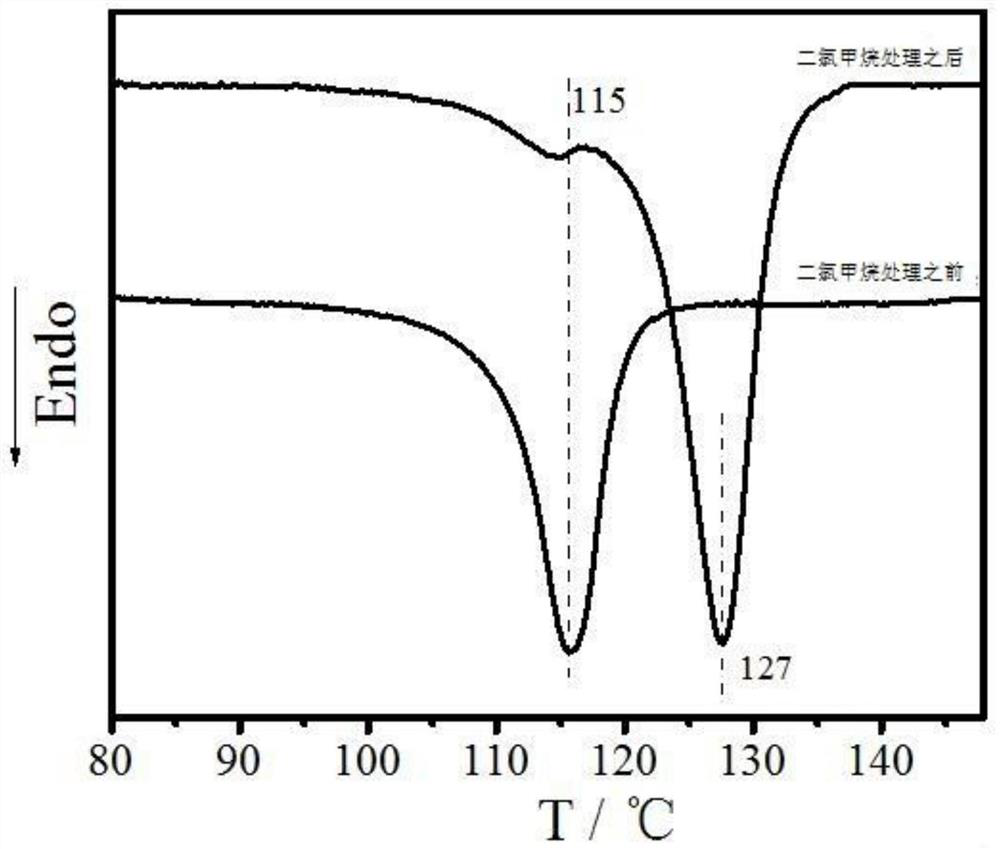

[0029] Since there are different mechanical orientations in the tableting process, the thermal history was eliminated after the sample tablet was prepared: the temperature was raised from room temperature to 200 °C at 10 °C / min on the linkam stretching hot stage and kept at a constant temperature for 5 min, and then the temperature was 10 °C / min. ℃ / min cooling to 100 ℃ constant temperature 250min isothermal crystallization is complete, and then cooling to 30 ℃ at 10 ℃ / min to obtain II crystal.

[0030] The II crystal (melt processing) of isotactic poly-1-butene is obtained through the above preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com