Incomplete penetration defect elimination method based on UG programming trajectory control

A trajectory control, incomplete penetration technology, applied in the field of friction stir welding, can solve the problems of thinning of welds and low success rate of repair welding, so as to avoid loss of mechanical properties, avoid incomplete penetration defects, and eliminate incomplete penetration defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with embodiment.

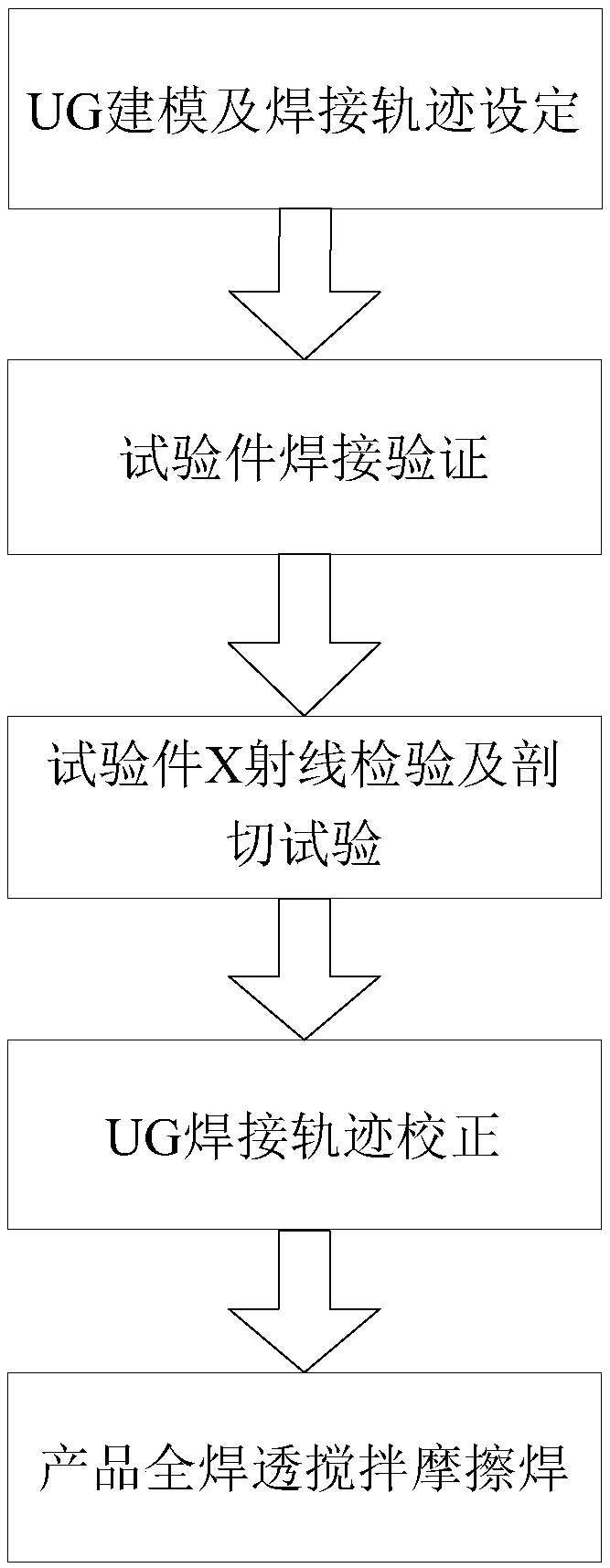

[0016] A method for eliminating incomplete penetration defects based on UG programming trajectory control provided by a preferred embodiment of the present invention includes the following steps:

[0017] Step 1: UG modeling and welding track setting. The product modeling should be completed in the UG software, and the welding trajectory of the model, that is, the tool path trajectory should be set. The tool path trajectory should be set according to the trajectory of the stirring needle tip.

[0018] Step 2: Test piece welding verification. The friction stir welding test is carried out with the test piece product that is exactly the same as the product size and other technical indicators to reflect the real product welding process, and the assembly fastening form and welding sequence are recorded;

[0019] Step 3: X-ray inspection and cutting test of the test piece. Use X-rays t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com