Gypsum-based self-healing high-strength wall material and preparation method thereof

A wall material and self-healing technology, applied in the field of building materials, can solve the problems of increased material use and maintenance costs, poor heat resistance of polyvinyl alcohol fiber, and low softening and decomposition temperature, so as to improve resource utilization and avoid Effect of loss of mechanical properties, improvement of mechanical properties and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

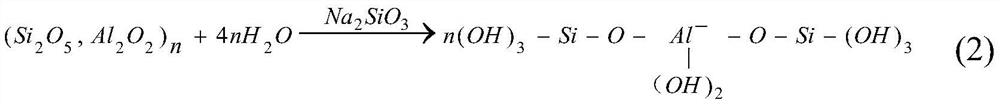

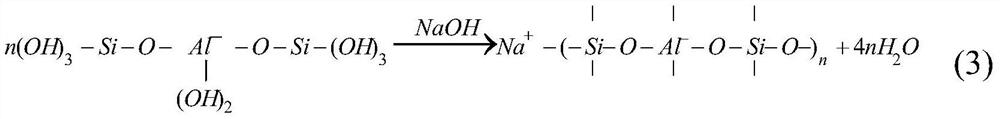

Method used

Image

Examples

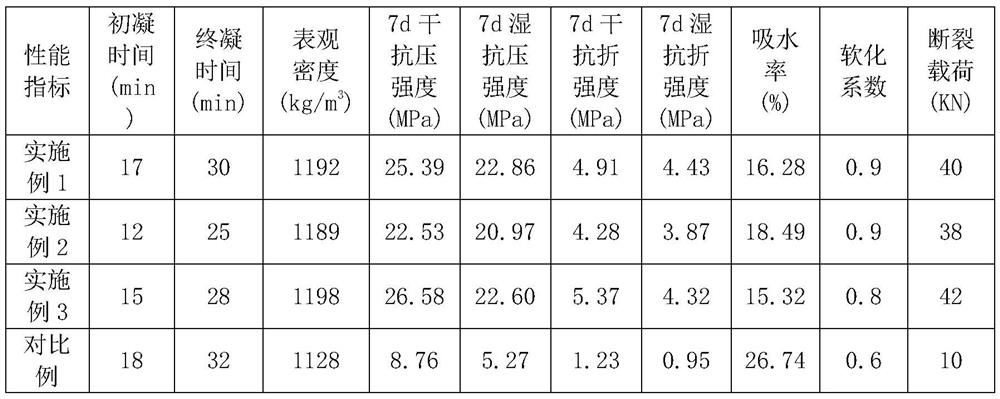

Embodiment 1

[0032] A gypsum-based self-healing high-strength wall material, the wall material includes the following components in parts by weight: 42 parts of building gypsum, 9 parts of P·C32.5 composite Portland cement, 4 parts of metakaolin, spherical polyurethane Encapsulated sodium silicate solution 5 parts, alkali-resistant glass fiber 2 parts, dispersion sol 1 part (of which diatomite 18 parts, ethylene-vinyl acetate copolymer 15 parts, methyl methacrylate 60 parts, titanate coupling 6.5 parts of agent, 0.5 parts of cumene hydrogen peroxide), 1 part of calcium chloride modified sepiolite powder, 1 part of liquid water glass, and 35 parts of tap water. Among them, the construction gypsum is α hemihydrate gypsum, the fineness (0.08mm sieve) is 2.1%, CaSO 4 The content is 98.3%; the activity index of metakaolin is 120; the solid content of spherical polyurethane encapsulated sodium silicate solution is 53%, and the modulus is 1.2; the diameter of alkali-resistant glass fiber is 3 μm,...

Embodiment 2

[0038] A gypsum-based self-healing high-strength wall material. The wall material includes the following components in parts by weight: 24 parts of desulfurized gypsum, 20 parts of phosphogypsum, 5 parts of CA-50-A6 aluminate cement, and S95 grade slag 5 parts, 6 parts of sodium silicate solution encapsulated in spherical polyurethane capsules, 2 parts of alkali-resistant glass fiber, 2 parts of dispersion sol (including 20 parts of diatomaceous earth, 14 parts of ethylene-vinyl acetate copolymer, 58 parts of methyl methacrylate, 7.6 parts of titanate coupling agent, 0.4 parts of cumene hydroperoxide), 1.5 parts of calcium chloride modified sepiolite powder, 1.5 parts of liquid water glass, and 33 parts of tap water. Among them, the fineness of desulfurized gypsum (0.08mm sieve) is 3.0%, CaSO 4 The content is 95.5%; the fineness of phosphogypsum (0.08mm sieve) is 3.5%, CaSO 4 The content is 91.7%; the solid content of spherical polyurethane capsule-encapsulated sodium silicat...

Embodiment 3

[0044] A gypsum-based self-healing high-strength wall material, the wall material includes the following components in parts by weight: 18 parts of building gypsum, 22 parts of fluorogypsum, 3 parts of P·C32.5 composite silicate water, S95 grade 4 parts of slag, 3 parts of metakaolin, 5 parts of spherical polyurethane encapsulated sodium silicate solution, 3 parts of alkali-resistant glass fiber, 3 parts of dispersed sol (including 17 parts of diatomite, 15 parts of ethylene-vinyl acetate copolymer, methyl 60 parts of methyl acrylate, 7.6 parts of titanate coupling agent, 0.4 parts of cumene hydroperoxide), 2 parts of calcium chloride modified sepiolite powder, 1 part of liquid water glass, 36 parts of tap water. Among them, the construction gypsum is α hemihydrate gypsum, the fineness (0.08mm sieve) is 2.1%, CaSO 4 The content is 98.3%; the fineness of fluorine gypsum (0.08mm sieve) is 2.9%, CaSO 4 The content is 90.2%; the activity index of metakaolin is 120; the solid cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com