Positive electrode sheet and its preparation method and energy storage device

A technology of energy storage device and positive electrode sheet, applied in battery electrodes, non-aqueous electrolyte battery electrodes, structural parts, etc., can solve the problems of secondary battery thermal runaway, electrolyte thermal runaway, aluminum foil short circuit, etc., to improve safety performance, The effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

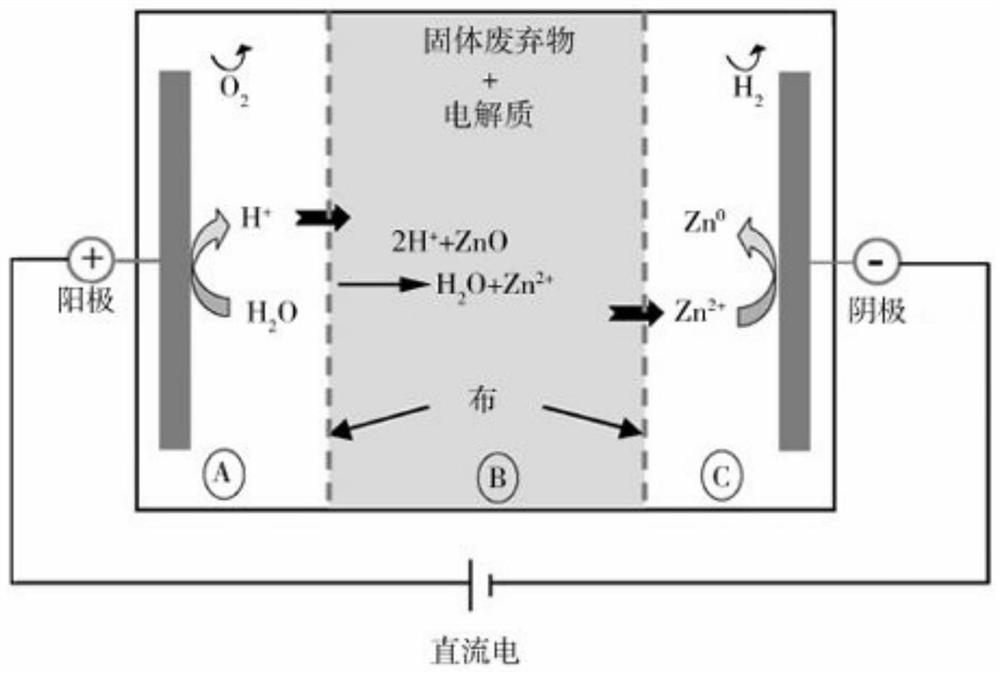

[0032]The method for preparing a positive electrode sheet according to the second aspect of the present invention is used to prepare the positive electrode sheet according to the first aspect of the present invention, comprising the steps of: using direct current as a power source, placing aluminum foil in a reaction tank as an anode, and turning on the power source for continuous Anodizing is to form an aluminum oxide layer in situ on the surface of the aluminum foil; the positive electrode slurry containing the positive electrode active material is uniformly coated on one or both surfaces of the aluminum foil, and the positive electrode sheet is obtained by drying and cold pressing.

[0033]In the method for preparing the positive electrode sheet according to the second aspect of the present invention, refer tofigure 1 , The zinc metal negative electrode can be placed in the reaction tank as the cathode.

[0034]In the method for preparing the positive electrode sheet according to the s...

Embodiment 1

[0050](1) Preparation of positive electrode sheet

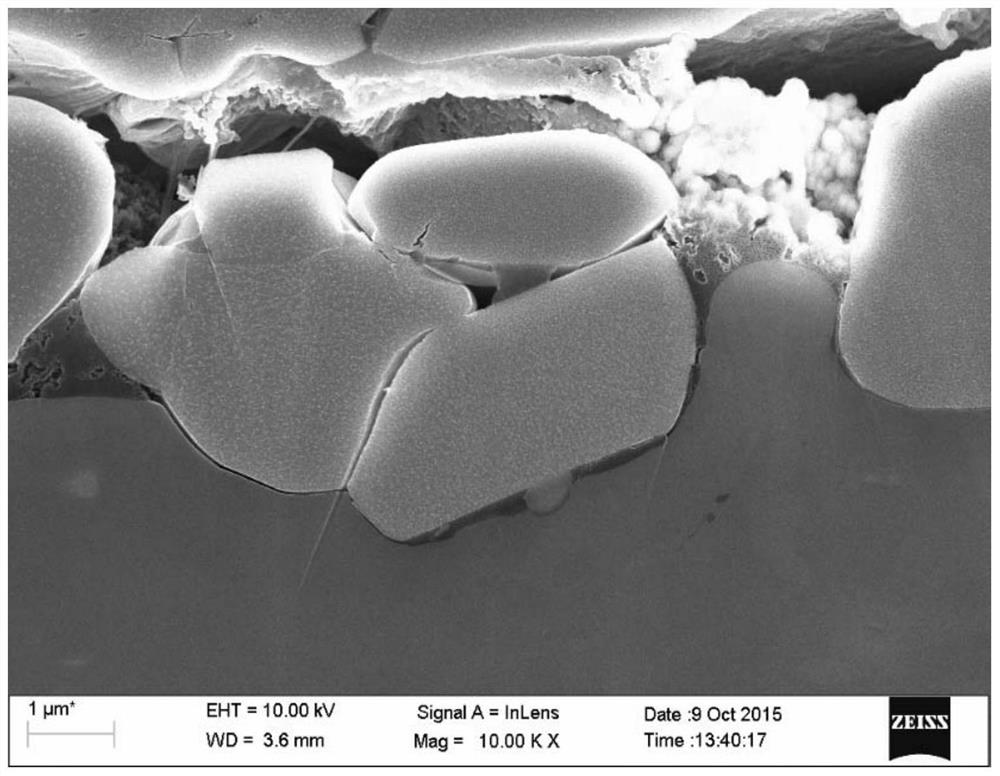

[0051]Use direct current as the power source, put the aluminum foil (thickness 12μm) in the reaction tank as the anode, and place the zinc metal negative electrode in the reaction tank as the cathode. Turn on the power and perform continuous anodizing treatment to in-situ on the surface of the aluminum foil An aluminum oxide layer is formed to obtain an aluminum foil (as a positive electrode current collector) with an aluminum oxide layer formed on the surface in situ, wherein the power supply voltage is 7V, the reaction time is 4 min, and the thickness of the aluminum oxide layer is 200 nm.

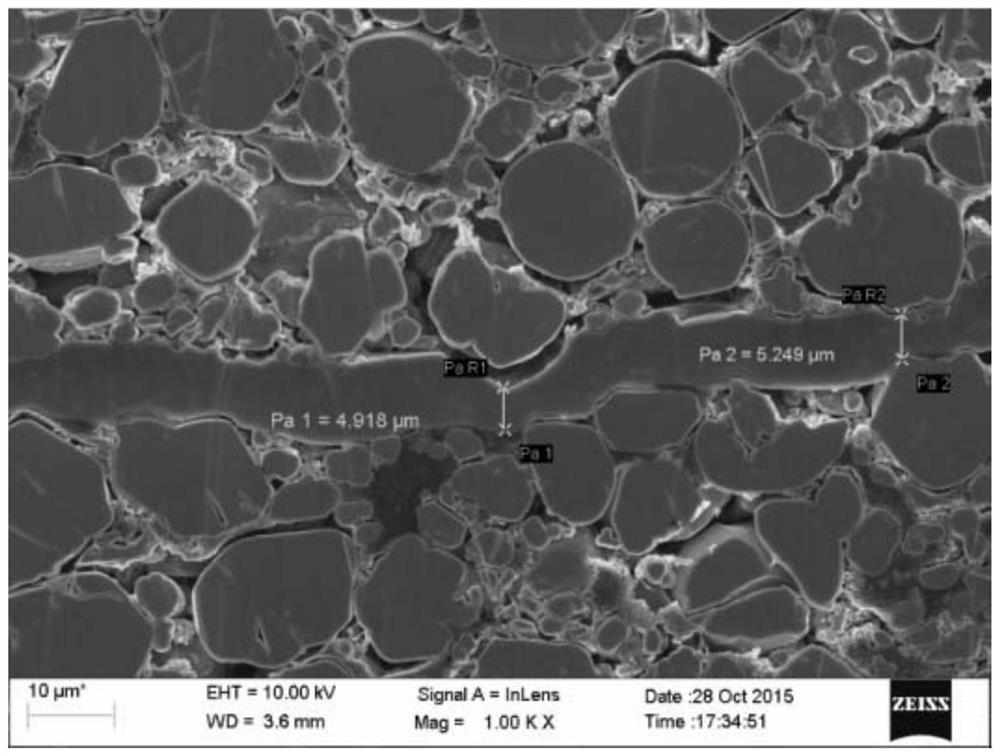

[0052]The positive active material Li2CoO2, Conductive agent acetylene black, binder polyvinylidene fluoride (PVDF) in the N-methylpyrrolidone solvent system according to the weight ratio of 94:3:3, after fully stirring and mixing uniformly, coating on the two surfaces of the above aluminum foil After drying and cold pressing, the positive electrod...

Embodiment 2

[0062]The preparation method of the lithium ion secondary battery is the same as that of Example 1, the difference is:

[0063](1) Preparation of positive electrode sheet

[0064]The compacted density of the positive electrode membrane after cold pressing is 4.1g / cm3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com