Thick oil SAGD horizontal well real-time output monitoring-underground control implementation method

A technology for horizontal wells and heavy oil, applied in wellbore/well components, measurement, earth-moving drilling and production, etc., can solve the problems of high cost, high operation risk, untimely control of liquid production profile, etc., to achieve efficient development and solve operations. long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

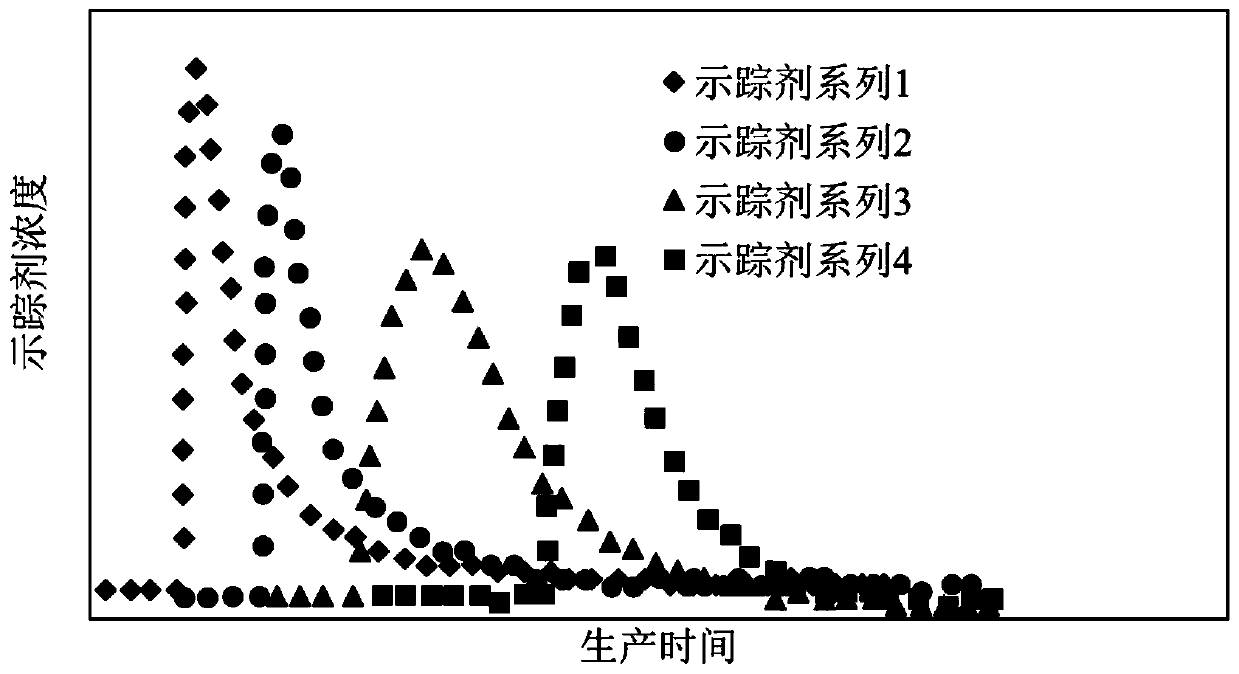

Image

Examples

Embodiment approach

[0022] A heavy oil SAGD horizontal well production monitoring and well completion implementation method, comprising the following steps:

[0023] S1. Collect and analyze relevant data such as geology, well logging, core analysis, and drilling trajectory of the reservoir to realize the refined characteristics of the SAGD horizontal well near the wellbore (interlayer, reservoir thickness, gas cap, top water, etc.) reservoir permeability, etc.) description;

[0024] S2. According to the detailed characterization results of SAGD horizontal wells, preliminarily determine the location and quantity of horizontal well segmented monitoring; the basic principle of horizontal well segmental optimization is to give priority to high-quality reservoirs, and the combination of layers with similar or consistent physical properties is good. The intervals with good physical properties and crude oil indications are preferentially separated into a unit with relatively concentrated intervals with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com