A kind of sound wave transducer making holder

A technology of acoustic wave transducers and holders, which is applied in the directions of measurement, wellbore/well parts, connecting components, etc., can solve the problems of transducer quality and consistency, avoid changes in clamping force, eliminate deviation, etc. Oblique effect, highly consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

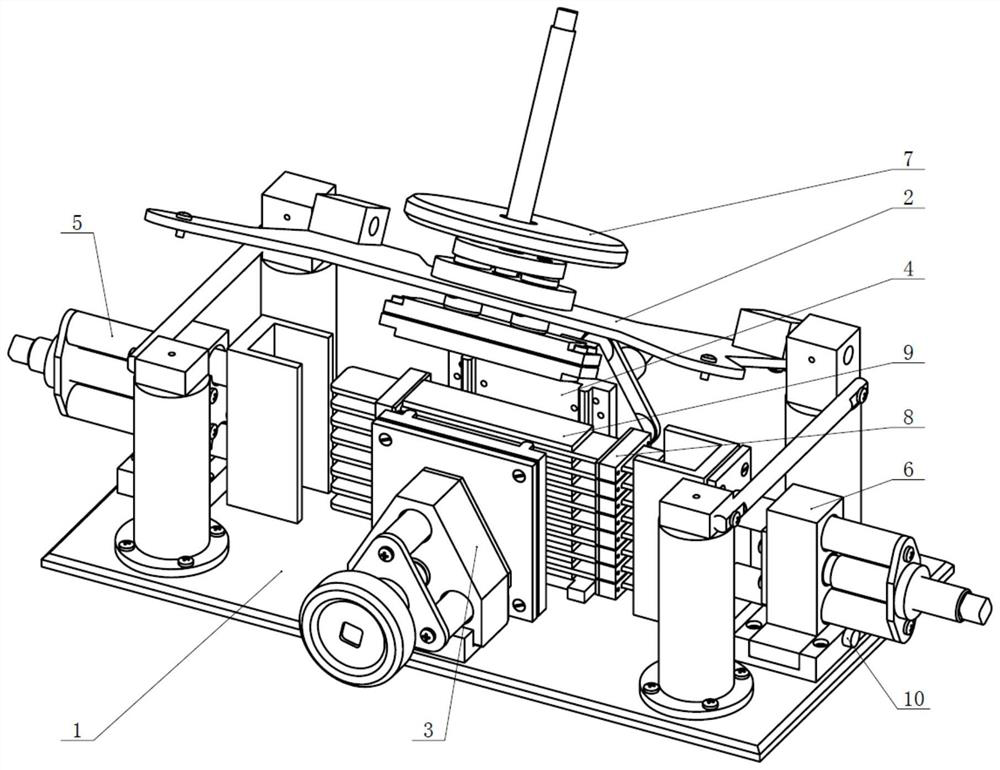

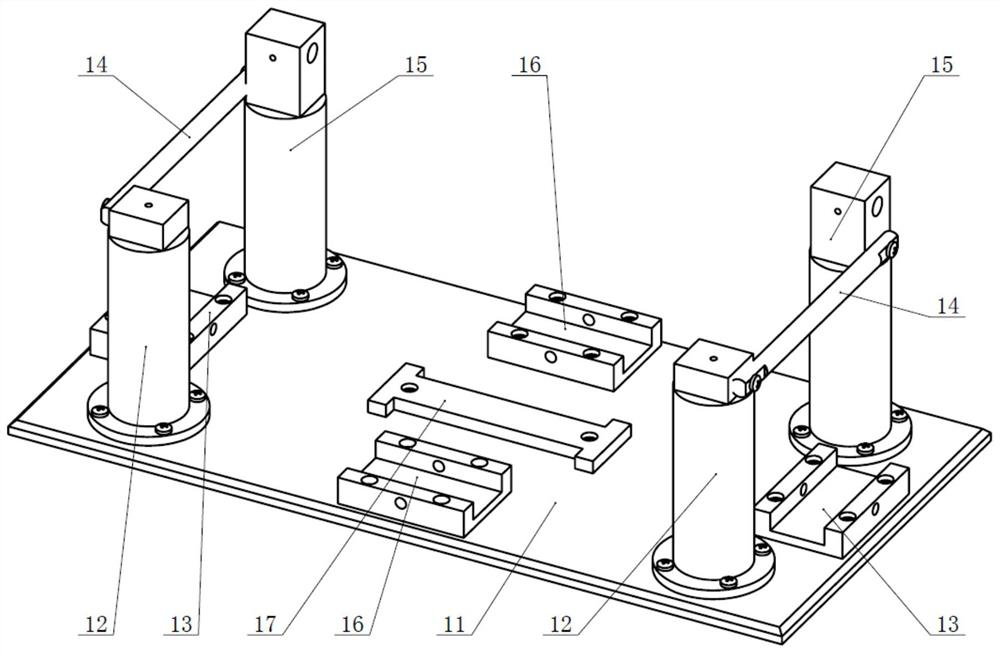

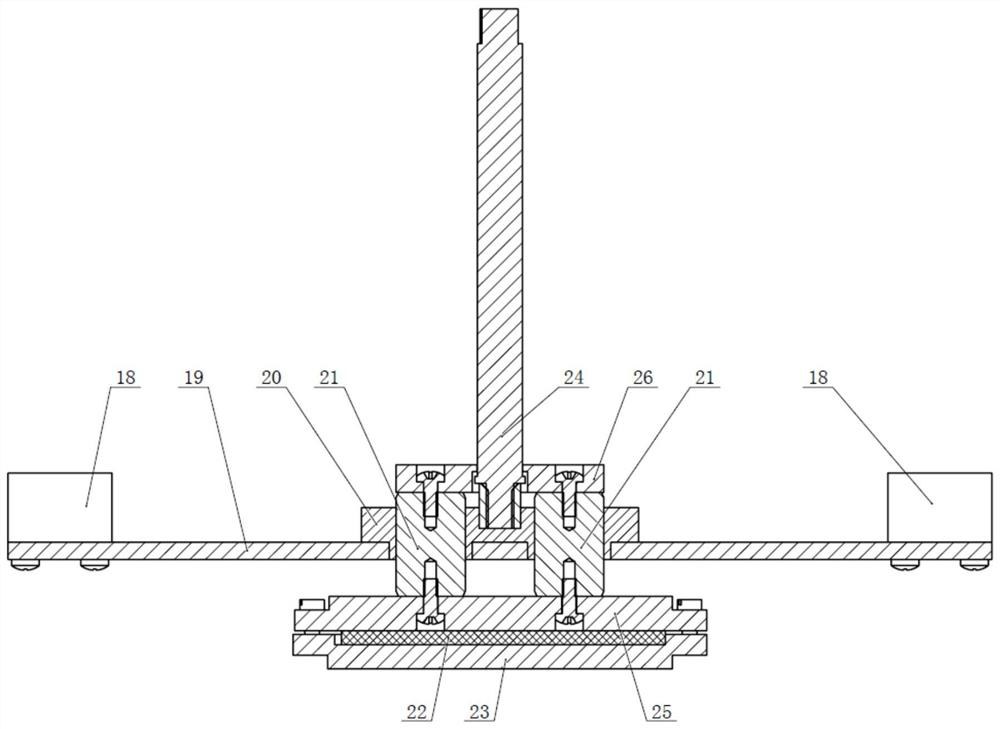

[0035] see Figure 1 to Figure 8 , The present invention includes a bottom plate assembly 1, a top plate assembly 2, a positive correction assembly 3, a positive fixed assembly 4, a lateral correction assembly 6, a lateral fixed assembly 5, a slider assembly 8, a weight plate 7, and the like.

[0036] The positive correction component 3 and the positive fixed component 4 provide clamping and limiting in the X-axis direction, the lateral correction component 6, the lateral fixing component 5 and the slider component 8 provide clamping and limiting in the Y-axis direction, and the bottom plate component 1 and the top plate assembly 2 provide clamping in the Z-axis direction, and the weight plate 7 provides a constant clamping force in the Z-axis direction.

[0037] see figure 1 , the bottom plate assembly 1 is located at the bottom of the device, and all other componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com