Loose force transmission insulation flange and surface crack detection method thereof

A flange and loose sleeve technology, which is applied in the field of loose sleeve force transmission insulating flange and its surface crack detection, can solve the problems of short service life of insulating materials, high detection cost, multiple maintenance and replacement, etc., to prevent fading, Effects of reducing friction and compensating installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

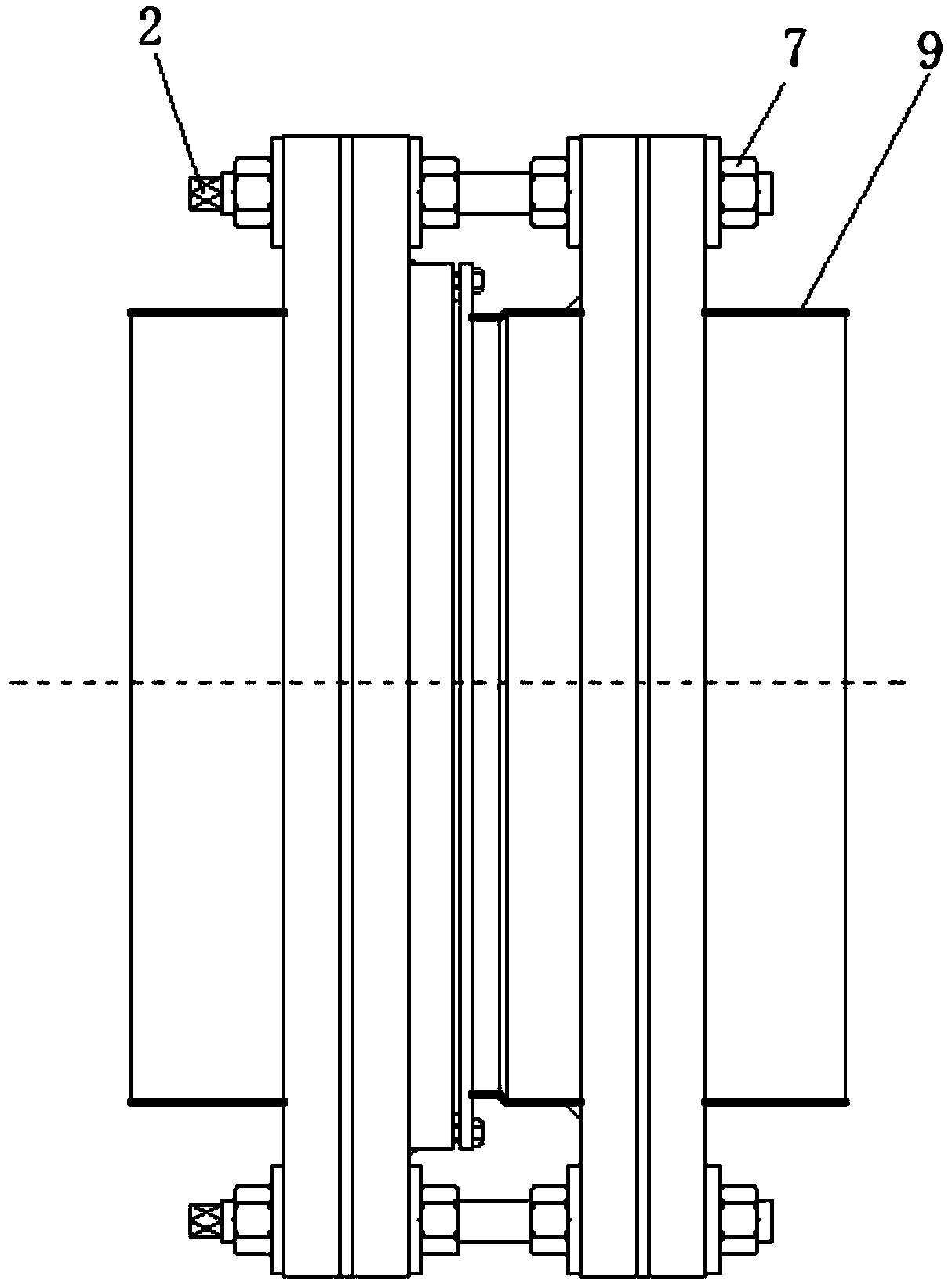

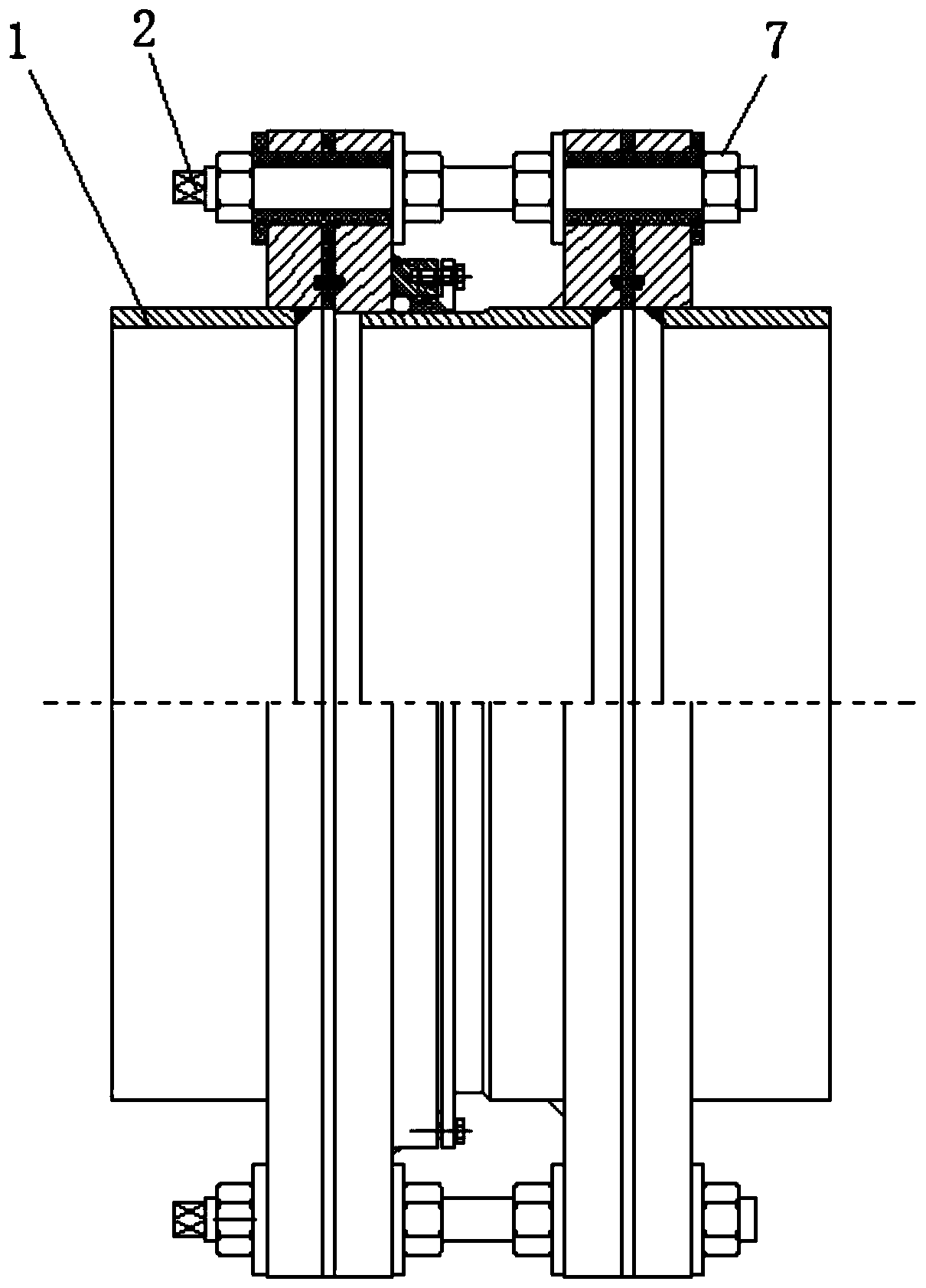

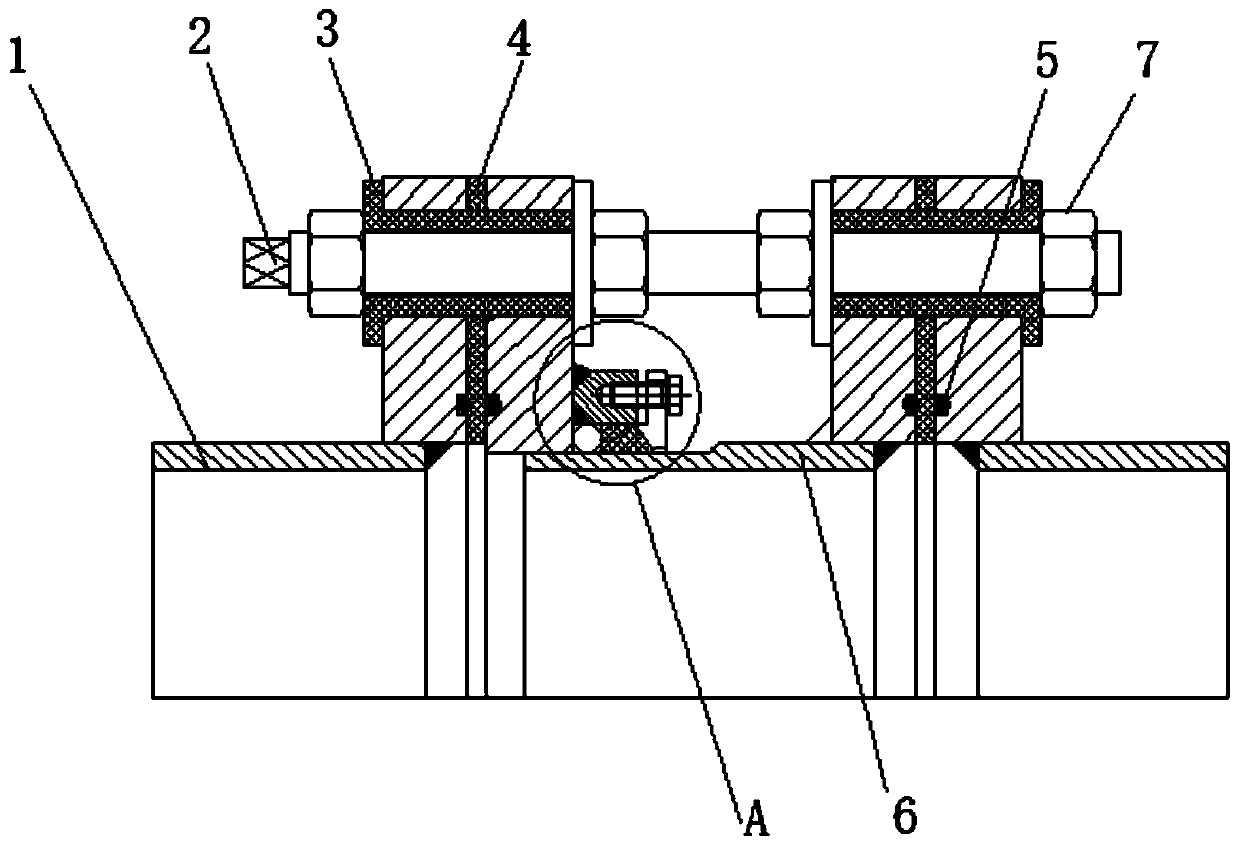

[0052] see figure 1 , figure 2 with image 3 , a loose sleeve force transmission insulating flange, including SR joint 6 and a pair of flange short tubes 1, a pair of flange short tubes 1 are respectively connected to the left and right ends of SR joint 6, flange short tube 1 and SR joint 6 There are insulating flange pads 4 and the first O-ring 5 at the connection of the SR joint 6 and the side end of the flange short pipe 1 are provided with a plurality of corresponding screw holes, and the screw holes on the SR joint 6 are threaded. There is a force transmission screw 2, and the left and right sides of the force transmission screw 2 are respectively threadedly connected with the screw holes on a pair of short flange pipes 1. There are many pairs of dowel nuts 7 connected to the force transmission screw 2, and the force transmission screw 2 is connected with the screw holes. An insulating sleeve 3 is provided between the inner walls, a sealing assembly 8 is connected to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap