Chirp spectral pattern cavity-less optical fiber Fabry-Perot filter and manufacturing method thereof

A manufacturing method and filter technology, applied in light guides, optics, instruments, etc., can solve problems such as low chirp rate, damage to chirp characteristics of interference spectrum, and low effective refractive index, etc., to achieve large chirp changes rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

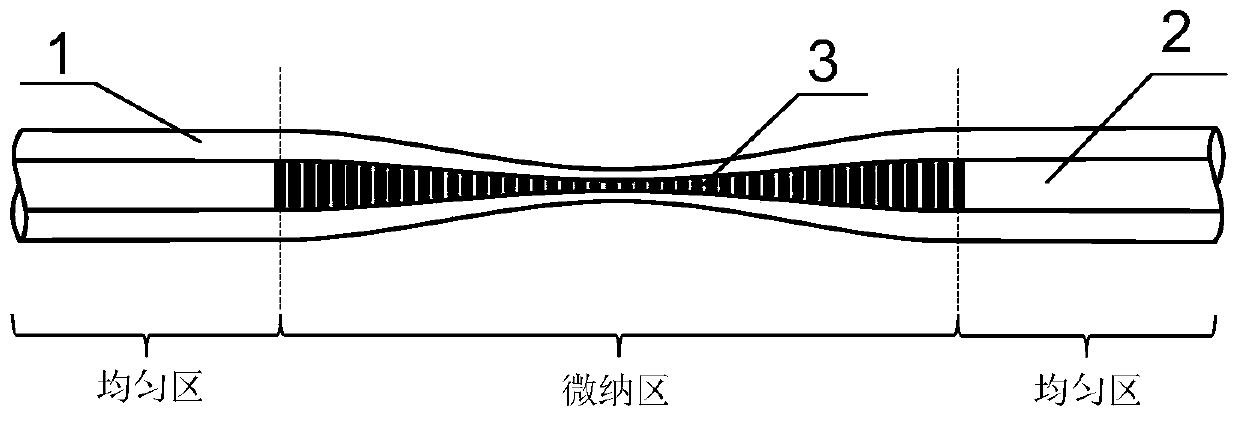

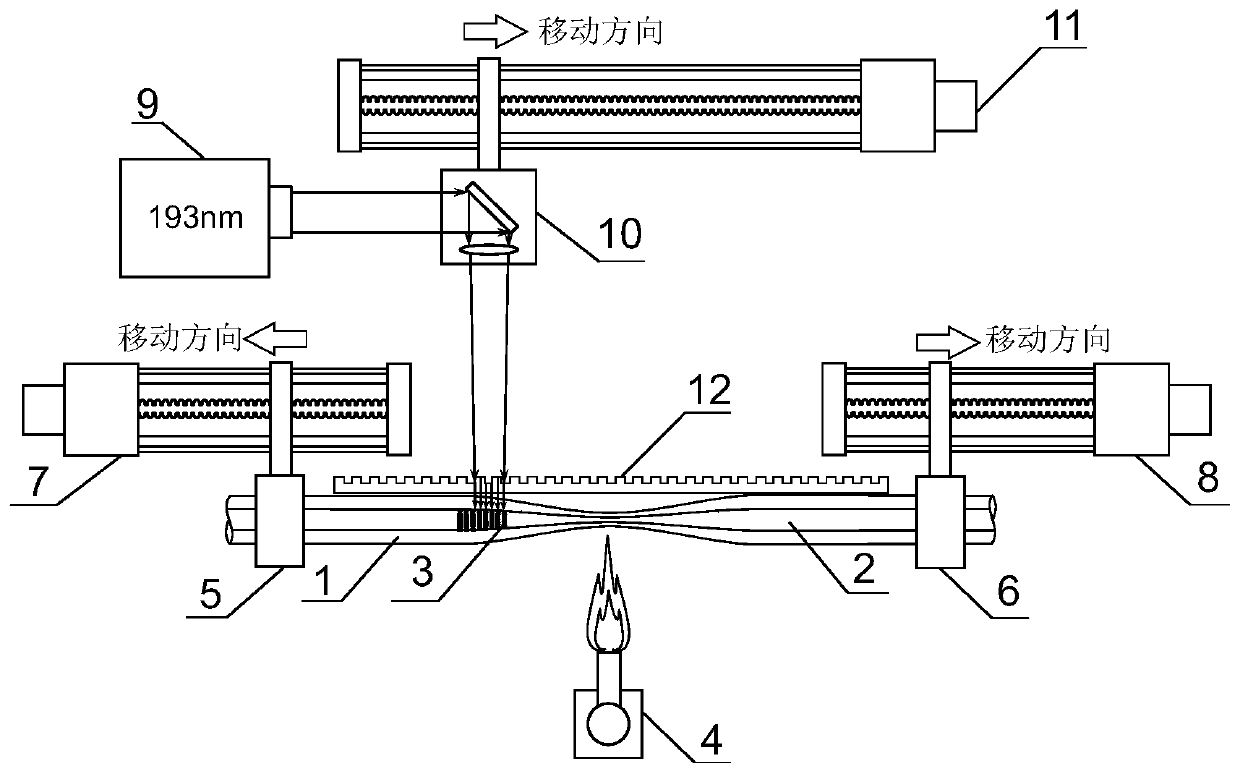

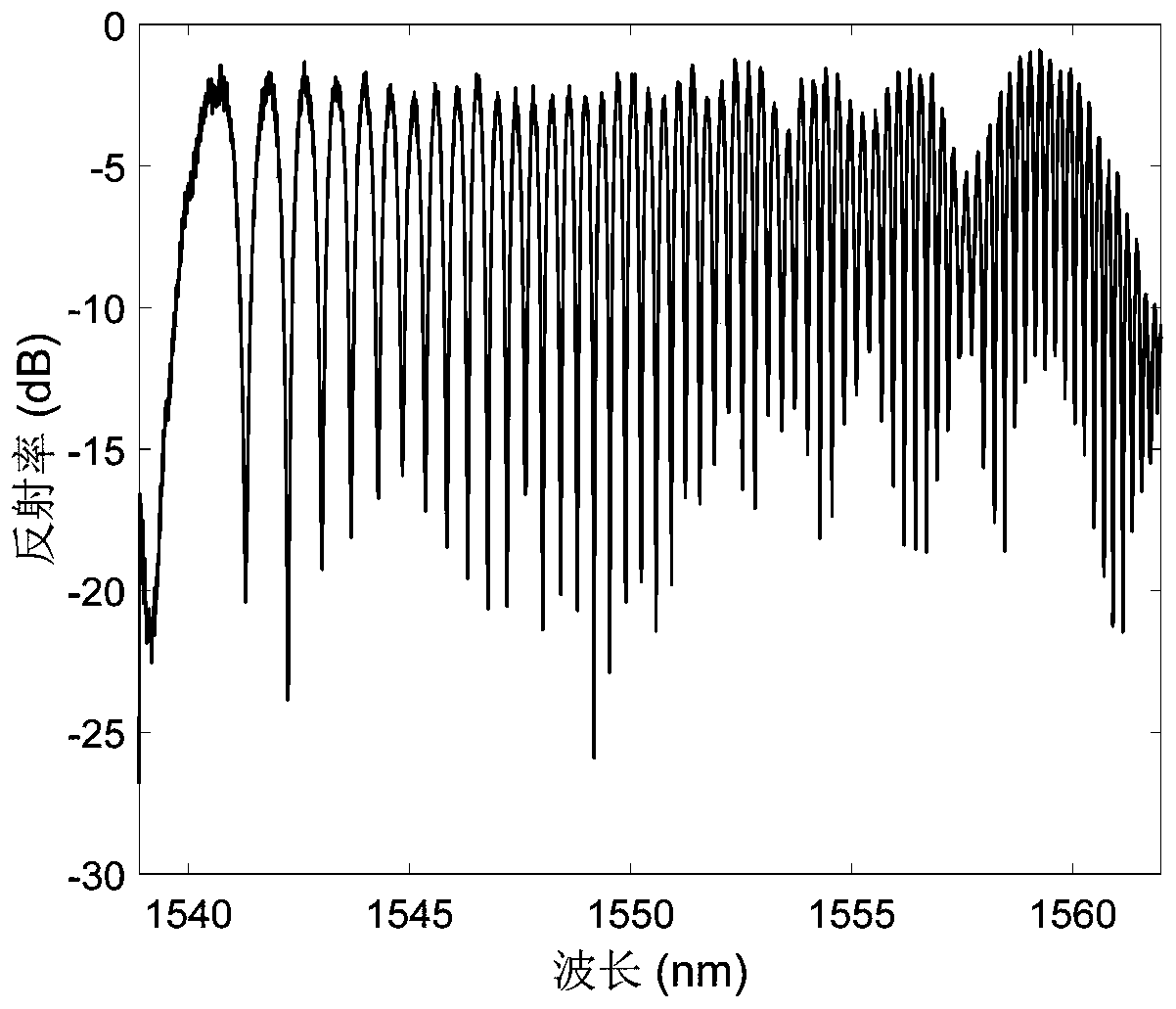

[0031] A chirped spectrum cavityless fiber Fabry-Perot filter, including a fused tapered multimode micro-nano fiber cladding 1, a multimode micro-nano fiber core 2 and continuously written equal-period Bragg gratings 3 parts. After continuously scanning and writing a long grating on the micro-nano transition region, although there is no cavity length in the formed structure, since the fiber micro-nano region can be regarded as the left and right parts centered on the thinnest position, the grating written on it It can also be two parts on the left and right. For a tiny grating segment with a certain diameter on the left side of the grating, there must be a tiny grating segment with the same diameter on the right side. The reflection wavelengths of the two are the same. The back and forth reflections between the small grating segments and finally form multi-beam interference. Similarly, multi-beam interference will also be formed in the tiny grating segment area inside the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com