Cooling assembly of linear motor rotor, linear motor rotor, linear motor and machine tool

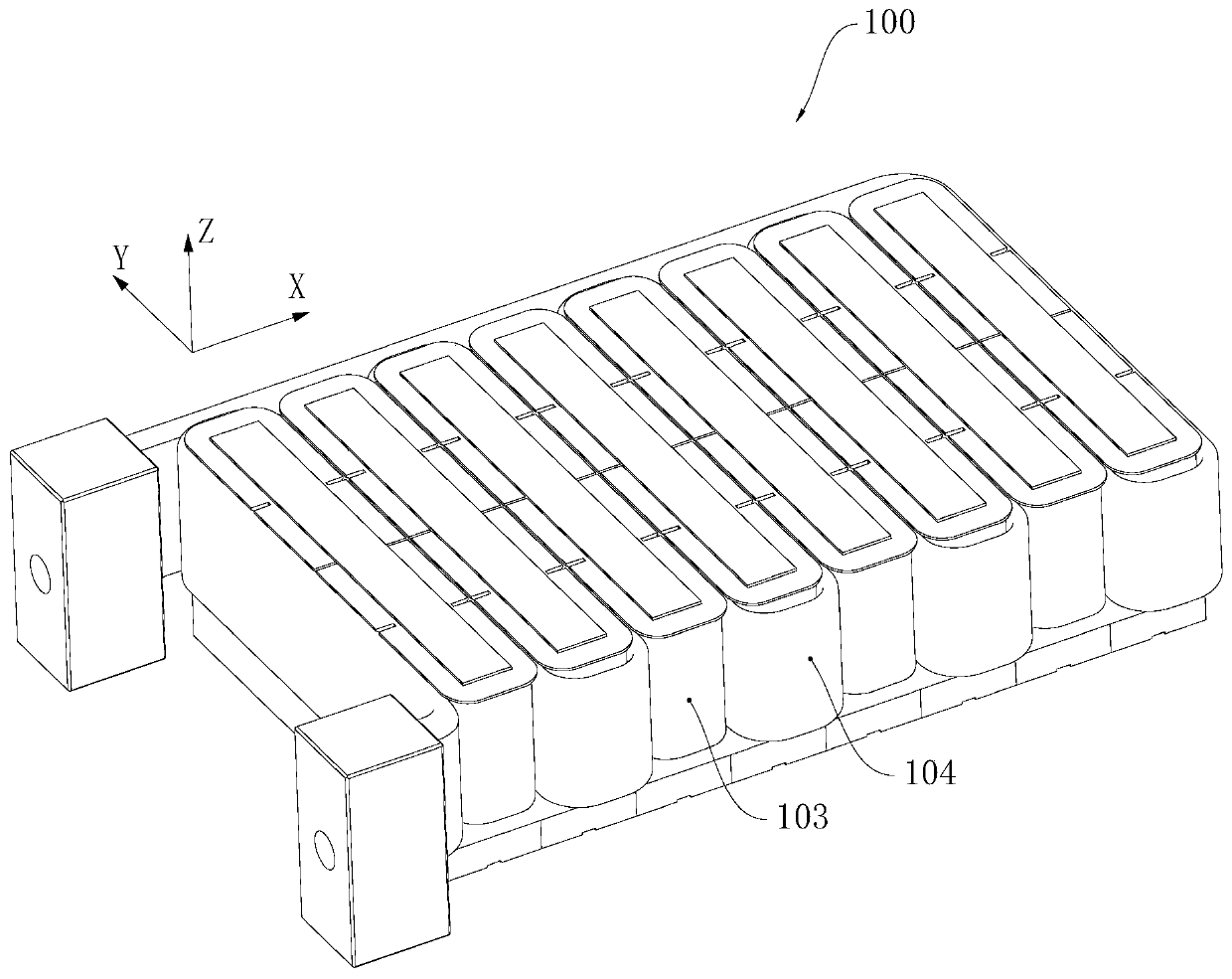

A technology for cooling components and linear motors, which is used in magnetic circuit rotating parts, metal processing machinery parts, maintenance and safety accessories, etc., and can solve the problem of uneven cooling of linear motor movers, large area of coil winding 103, and linear motor movers. Problems such as poor regional cooling can avoid local poor cooling and improve the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

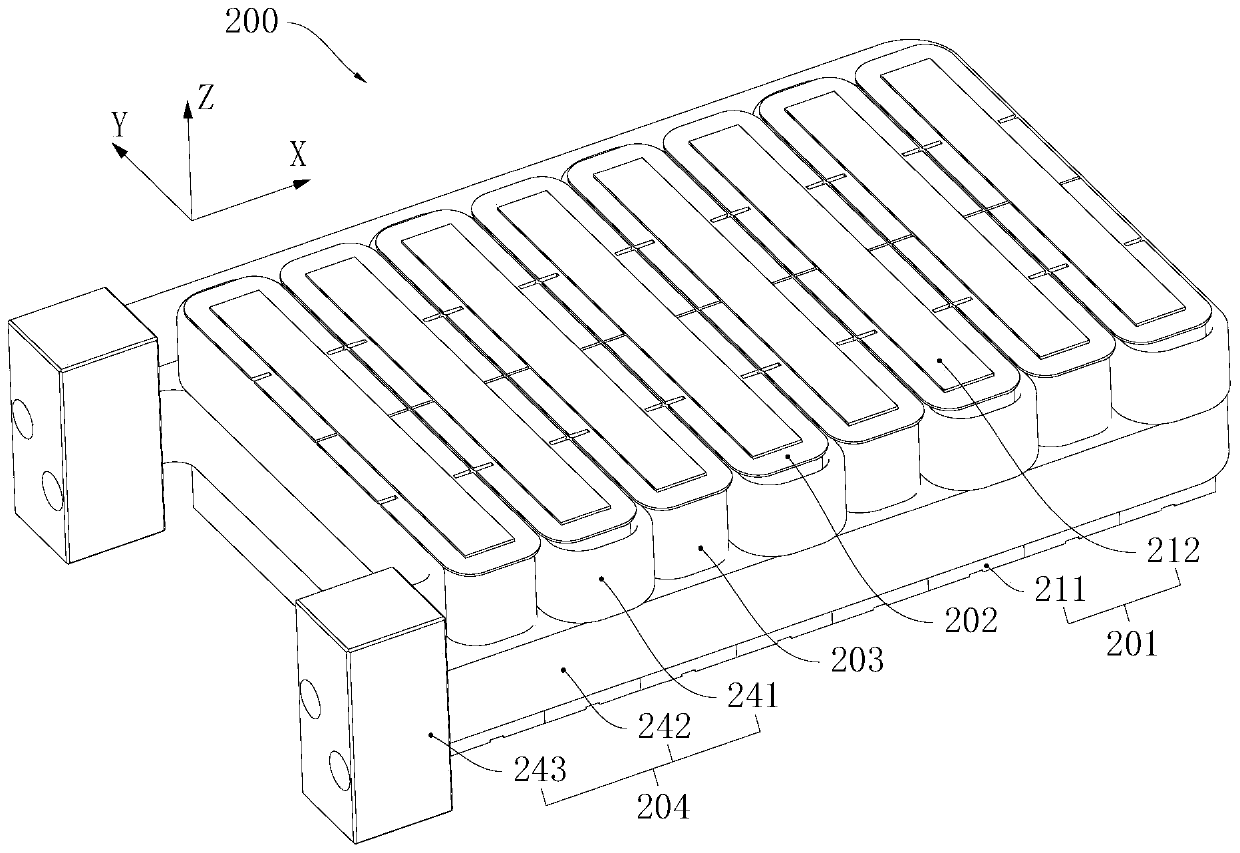

[0034] This example refers to figure 2 The coordinate system shown is described.

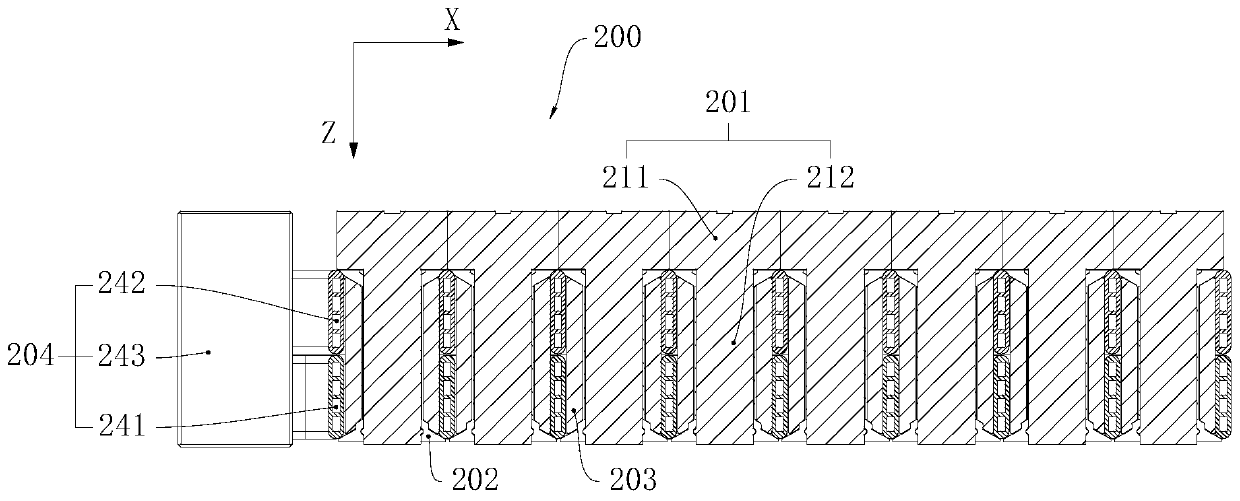

[0035] At least one feed system of the machine tool of this embodiment is driven by the linear motor of this embodiment. The linear motor of this embodiment includes a stator and a linear motor mover of this embodiment. Please refer to figure 2 and image 3 The linear motor mover of this embodiment includes a mover core 201 , an insulating frame 202 , a coil winding 203 and a cooling assembly 204 of this embodiment, and the cooling assembly 204 of this embodiment includes a cooling tube group and a cooling joint 243 .

[0036] Please refer to figure 2 and image 3 The mover core 201 has a main body 211 and a plurality of teeth 212 distributed along the X-axis direction, each tooth 212 protrudes from the main body 211 along the positive direction of the Z-axis, and the insulating skeleton 202 has a plurality of tooth sleeves, each The tooth sleeves are fixedly sheathed on each tooth portio...

Embodiment 2

[0044] Please refer to Figure 5 , in this embodiment, the first winding section 2412 communicates with the second straight section 2421 through the connector 244, the first cooling pipe 241 communicates with the second cooling pipe 242 in series, and the cooling joint 243 is independently provided with a liquid inlet channel and a liquid outlet The liquid inlet channel on the cooling joint 243 communicates with the first straight section 2411 , and the liquid outlet channel on the cooling joint 243 communicates with the second winding section 2422 . In this way, the cooling liquid flows through the first cooling pipeline 241 and the second cooling pipeline 242 sequentially, which can also achieve the purpose of uniformly cooling the linear motor mover.

[0045] Optionally, the series connection of the first cooling pipeline 241 and the second cooling pipeline 242 can also be that the first winding section 2412 and the second winding section 2422 are communicated through an ad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap