Low protein feed suitable for broiler chicken early feeding and preparation method of low protein feed

A low-protein technology for broiler chickens, which is applied in the field of low-protein feed for broiler chickens and its preparation, can solve problems such as poor absorption effect, increase shelf life, reduce disease risk and survival rate, and improve immunity force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

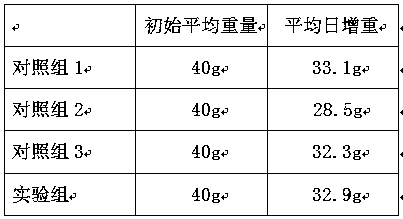

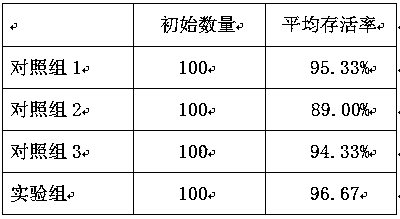

Examples

Embodiment 1

[0026] (1) Preparation of prefabricated materials: According to the chelation method of organic trace elements, 30 parts of lysine, 16 parts of methionine, and 10 parts of threonine are respectively chelated with 15 parts of trace elements, 8 parts of trace elements, and 5 parts of trace elements After chelation, the three amino acid chelated trace elements are mixed to obtain the basic prefabricated material;

[0027] (2) Crude protein pretreatment: use a pulverizer to pulverize the crude protein ration;

[0028] (3) Mixing of raw materials: Mix 60 parts of crude protein diet, 10 parts of phytase, 20 parts of peptidase, 20 parts of basic prefabricated material, 10 parts of multivitamin, 5 parts of salt and 10 parts of probiotic Stir evenly to obtain mixed feed A;

[0029] (4) Granulation: Put the mixed feed A in a pellet mill for granulation to obtain feed B;

[0030] (5) Coating: Feed B and 30 parts of bentonite were added to the coating machine for coating to obtain the f...

Embodiment 2

[0032] (1) Preparation of prefabricated materials: According to the chelation method of organic trace elements, 30 parts of lysine, 16 parts of methionine, and 10 parts of threonine are respectively chelated with 15 parts of trace elements, 8 parts of trace elements, and 5 parts of trace elements After chelation, the three amino acid chelated trace elements are mixed to obtain the basic prefabricated material;

[0033] (2) Crude protein pretreatment: use a pulverizer to pulverize the crude protein ration;

[0034] (3) Mixing of raw materials: 65 parts of crushed crude protein diet, 10 parts of phytase, 15 parts of peptidase, 15 parts of basic prefabricated material, 10 parts of multivitamins, 5 parts of table salt and 10 parts of probiotics were mixed and Stir evenly to obtain mixed feed A;

[0035] (4) Granulation: Put the mixed feed A in a pellet mill for granulation to obtain feed B;

[0036] (5) Coating: Feed B and 30 parts of bentonite were added to the coating machine ...

Embodiment 3

[0038] (1) Preparation of prefabricated materials: According to the chelation method of organic trace elements, 30 parts of lysine, 16 parts of methionine, and 10 parts of threonine are respectively chelated with 15 parts of trace elements, 8 parts of trace elements, and 5 parts of trace elements After chelation, the three amino acid chelated trace elements are mixed to obtain the basic prefabricated material;

[0039] (2) Crude protein pretreatment: use a pulverizer to pulverize the crude protein ration;

[0040] (3) Mixing of raw materials: 70 parts of crushed crude protein diet, 10 parts of phytase, 10 parts of peptidase, 10 parts of basic prefabricated material, 10 parts of multivitamins, 5 parts of salt and 10 parts of probiotics were mixed and Stir evenly to obtain mixed feed A;

[0041] (4) Granulation: Put the mixed feed A in a pellet mill for granulation to obtain feed B;

[0042] (5) Coating: Feed B and 30 parts of bentonite were added to the coating machine for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com