Device for removing dust and cleaning aluminium panel

A cleaning device and technology for aluminum veneer, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of inability to collect dregs and low efficiency of surface treatment of aluminum veneers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

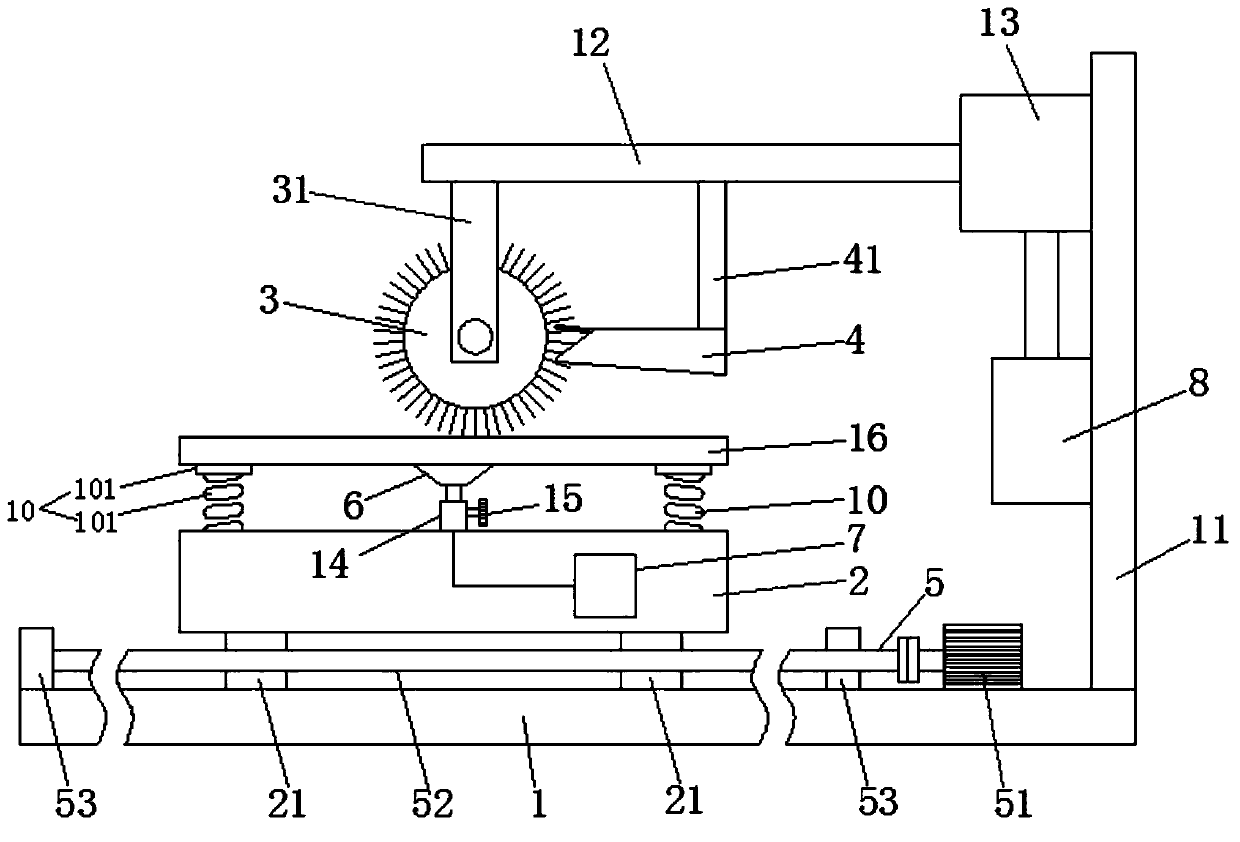

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

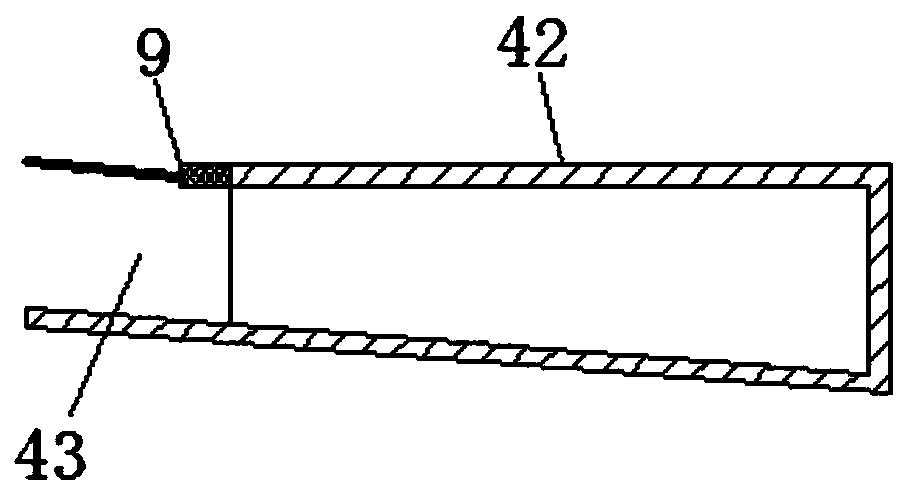

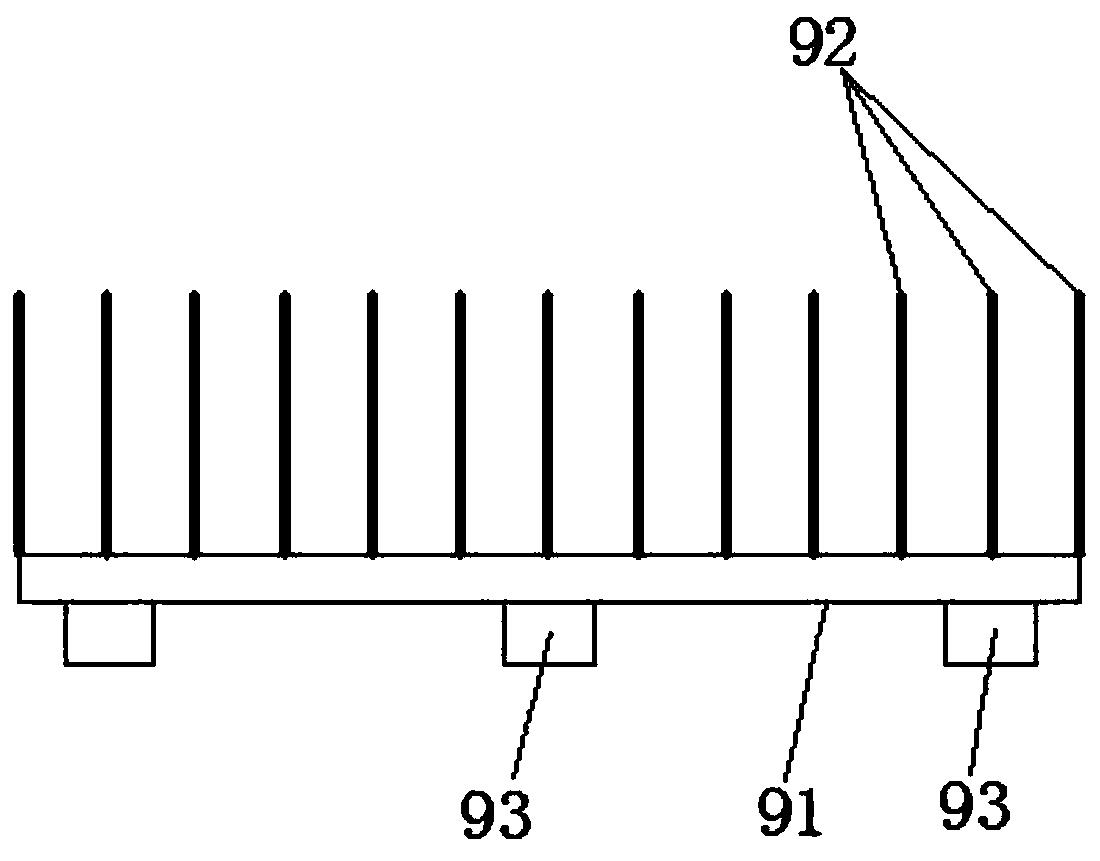

[0019] like Figure 1-3 As shown, an aluminum veneer dust removal and cleaning device includes a base 1, a workbench 2, a cleaning roller 3 and a roller cleaner 4; the base 1 is used as a carrier for setting various working parts, and the workbench 2 and the base 1 slide Connection, specifically, a slide rail (not shown) is set on the base 1, a slide block 21 is set on the workbench 2, and a feeding drive mechanism 5 for driving the reciprocating movement of the workben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com