Numerical control production line of U-rib components for bridge beams

A technology for rib components and bridges, applied in the field of CNC production lines, can solve the problems of manual auxiliary workload, huge equipment investment, unstable quality, etc., achieve the effects of reducing internal stress, improving product quality, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

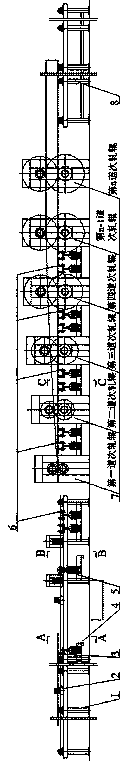

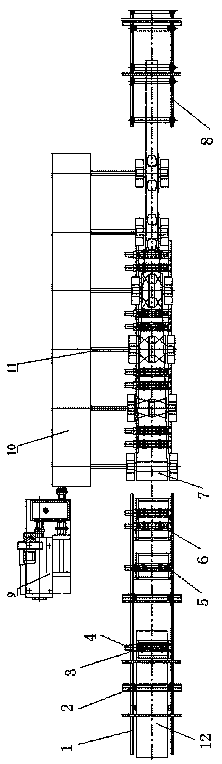

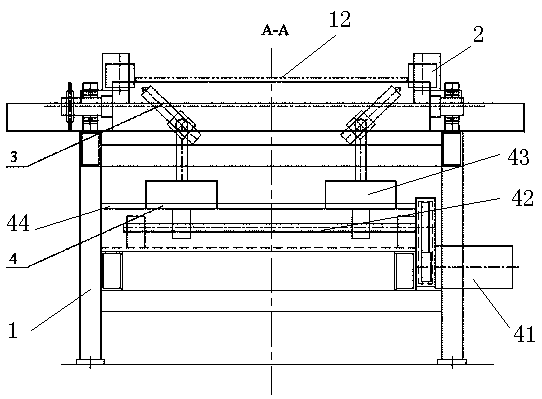

[0032] Such as Figure 1-8 As shown, the feeding and conveying device 1 is composed of a strip-shaped frame, conveying rollers on the frame, and a motor for driving the conveying rollers (the driving motor and corresponding components are omitted in the figure). A conveying roller is set at regular intervals, and when the conveying roller rotates, the steel plate workpiece 12 is conveyed from one end to the other. A pair of vertical positioning nip rollers 2 are arranged at regular intervals on the frame, and the vertical nip rollers are installed on the two slider seats of the centering positioning device 4, and move toward each other to hold (but not clamp dead) the workpiece. Limit the movement of the workpiece to the center of the frame to avoid deviation.

[0033] Bevel cutting torch 3 is installed below the workpiece moving surface in the frame. As mentioned above, the bevel torches are installed in pairs on the two sliding block seats of the centering and positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com