Self-repairing concrete taking recycled coarse aggregate as carrier and preparation method of self-repairing concrete

A recycled coarse aggregate and self-repairing technology, which is applied in the field of special building materials, can solve the problems of thick carrier modifier and inconvenient operation, etc., and achieve the effect of good concrete structure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

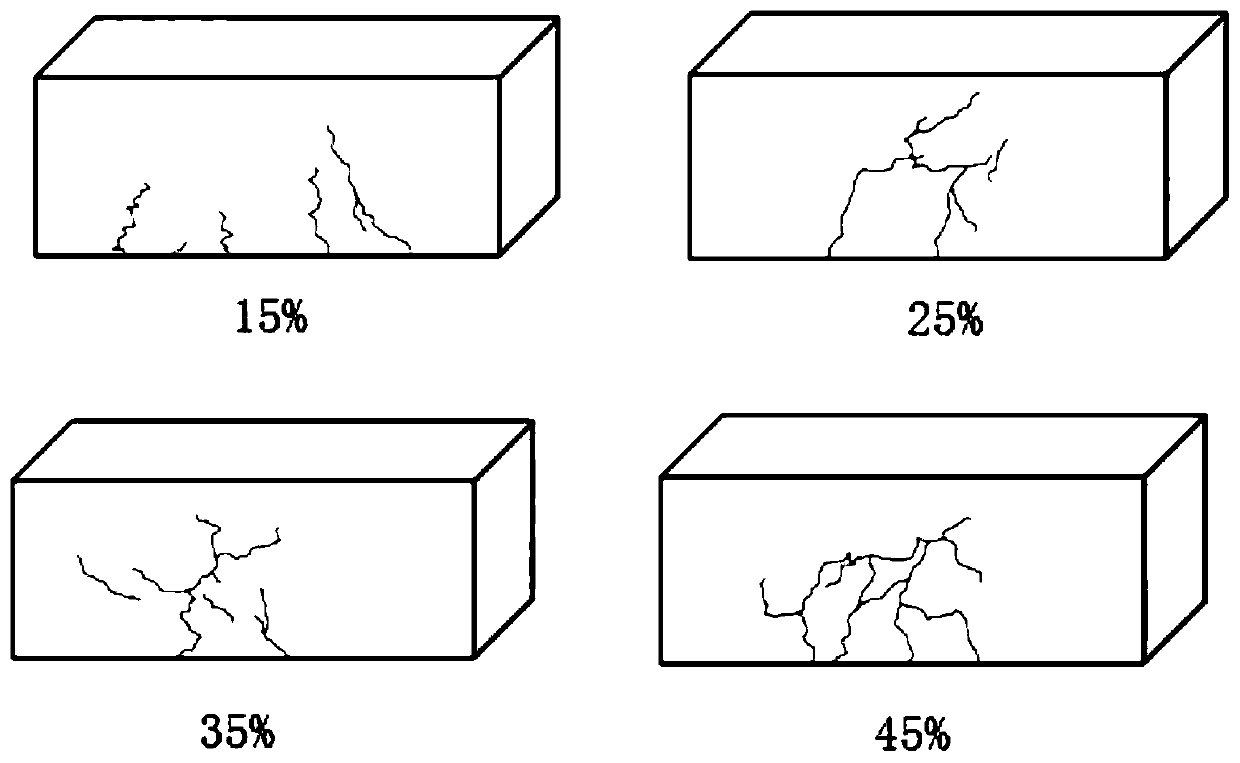

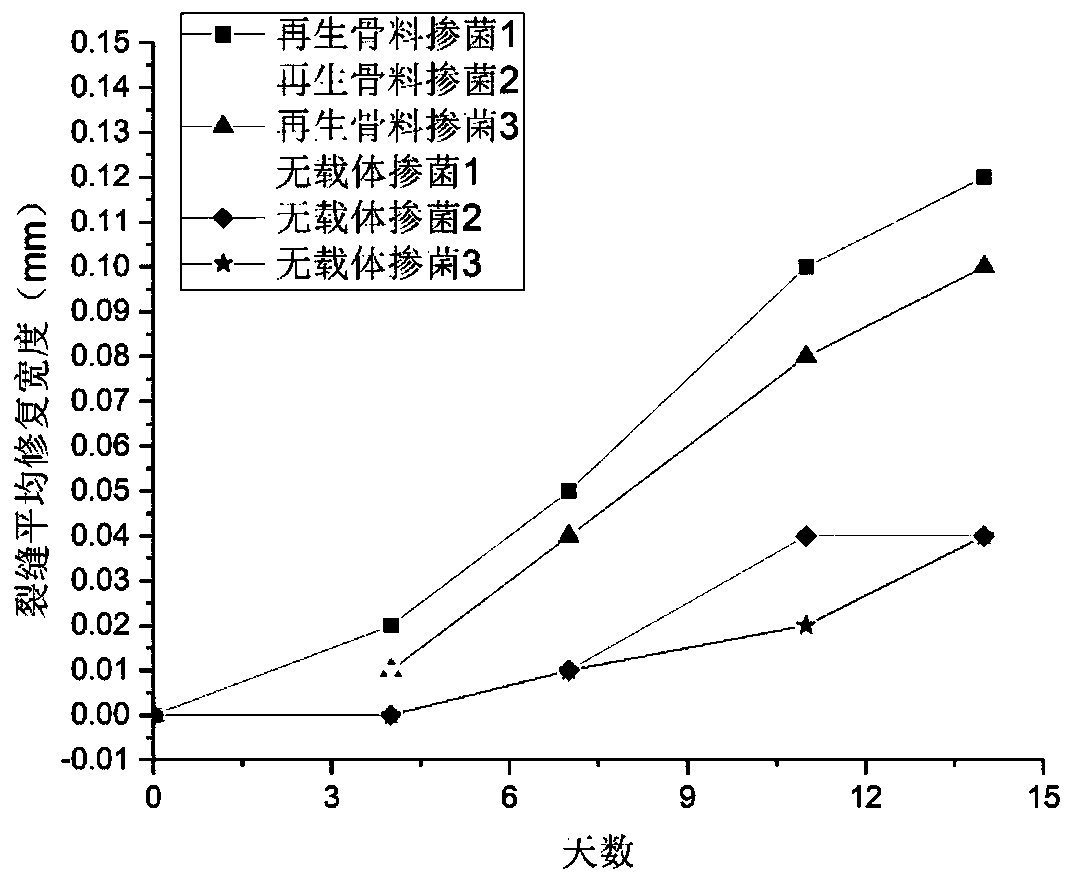

[0041] The self-repairing concrete added with self-repairing regenerated coarse aggregate in this embodiment includes concrete ingredients and self-repairing regenerated coarse aggregate. In terms of volume percentage, the self-repairing regenerated coarse aggregate accounts for 15%, 25%, and 35% of the self-repairing concrete % and 45%; in terms of mass ratio, the mixing ratio of sand, stone, cement and water in concrete is 3.10:1.75:1.00:0.50, and the self-repairing regenerated coarse aggregate is the regenerated coarse aggregate loaded with Bacillus pasteurianus.

[0042] A method for making self-repairing concrete with added self-repairing recycled coarse aggregate, comprising steps:

[0043] Step 1. The recycled coarse aggregate is taken from the concrete construction waste after the demolition of conventional civil and commercial buildings. After crushing, the particle size of the recycled coarse aggregate is 5-10mm gravel, and the apparent density is 2458kg / m 3 , the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com