Flat fin, microchannel heat exchanger and air conditioner

A microchannel and fin technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems affecting the drainage, defrosting performance, and water flow obstruction of microchannel heat exchangers, etc. Improve the user experience, reduce the amount of frost, and reduce the effect of wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

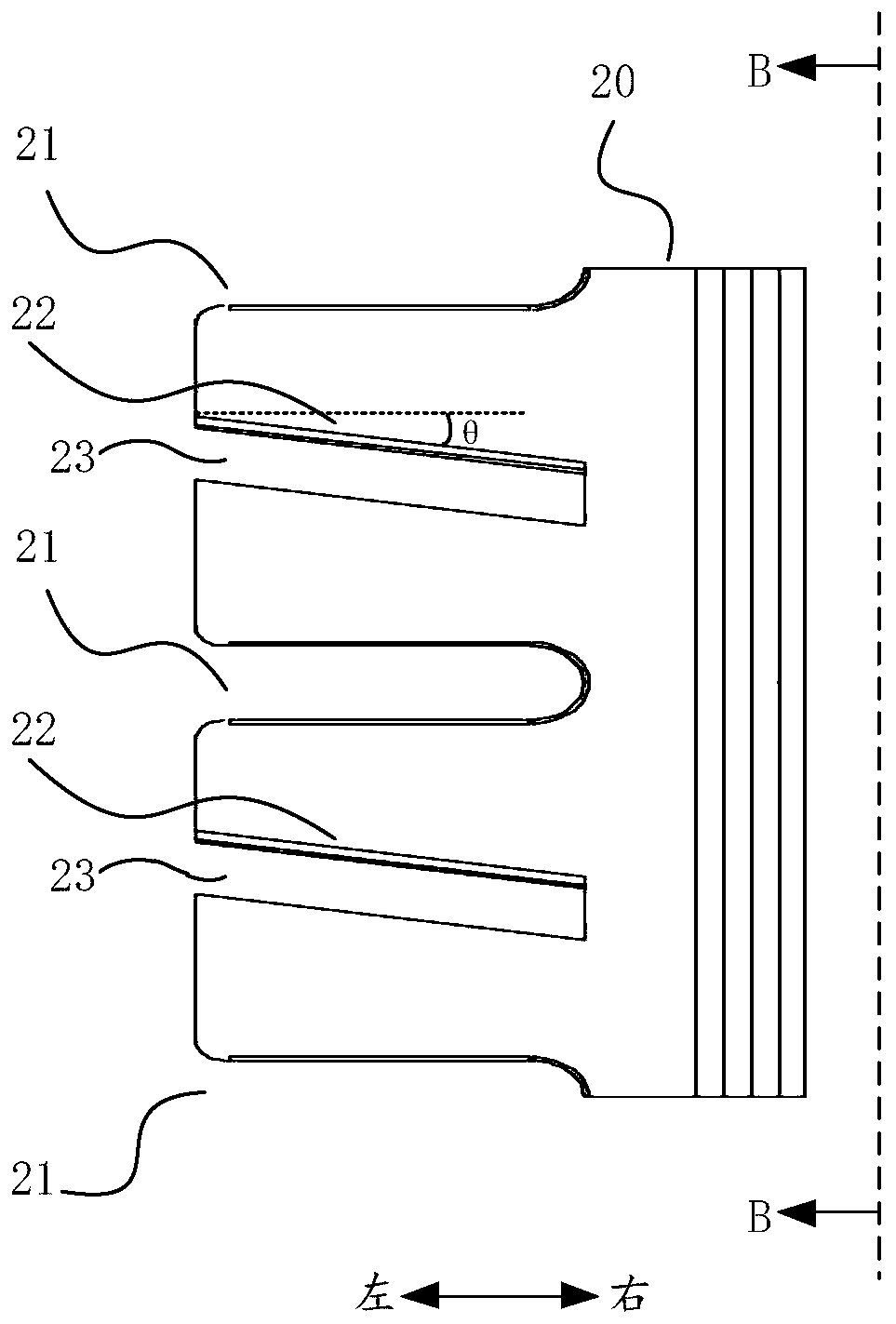

[0033] Such as image 3 , Figure 4 As shown, the flat fins 20 provided by the embodiment of the present invention are arranged along the vertical direction, wherein the flat fins 20 are provided with microchannel flat tube installation grooves 21 . in:

[0034] At least one side of the flat fin 20 is provided with a water guiding plate 22 perpendicular to the flat fin 20 . The water guide plate 22 is used to collect and guide the condensed water on the flat fins to the edge of the flat fins.

[0035] Specifically, the water guiding plate 22 is arranged at a certain angle with the horizontal plane, wherein the angle of the included angle is less than 30°. Exemplary, such as image 3 As shown, wherein, the angle θ<30° between the water guide plate 22 and the horizontal plane.

[0036] In one implementation, the water guide plate 22 can be as image 3 straight line shown. In other implementation manners, the water guiding plate 22 may also adopt structures of other shapes...

Embodiment 2

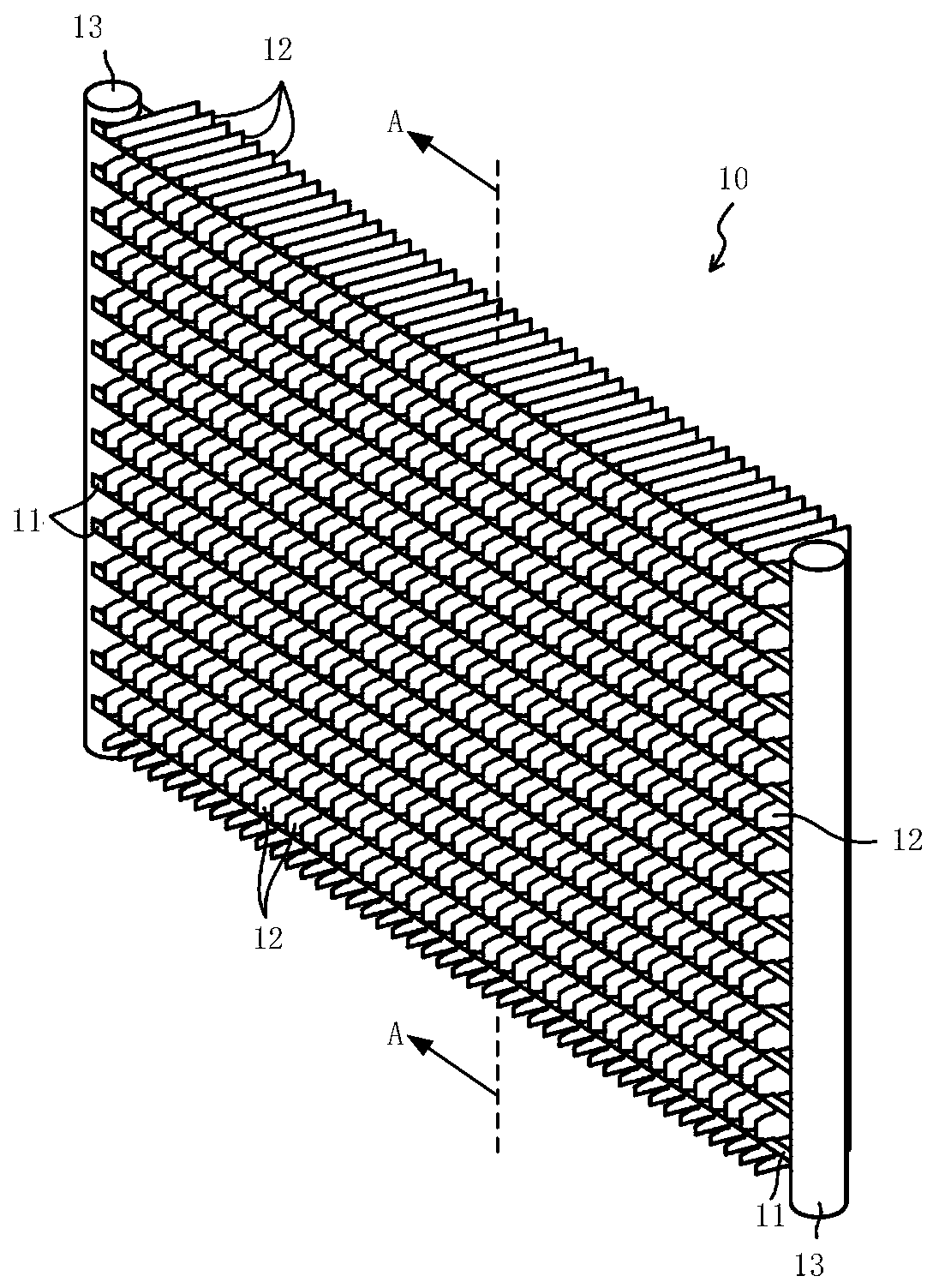

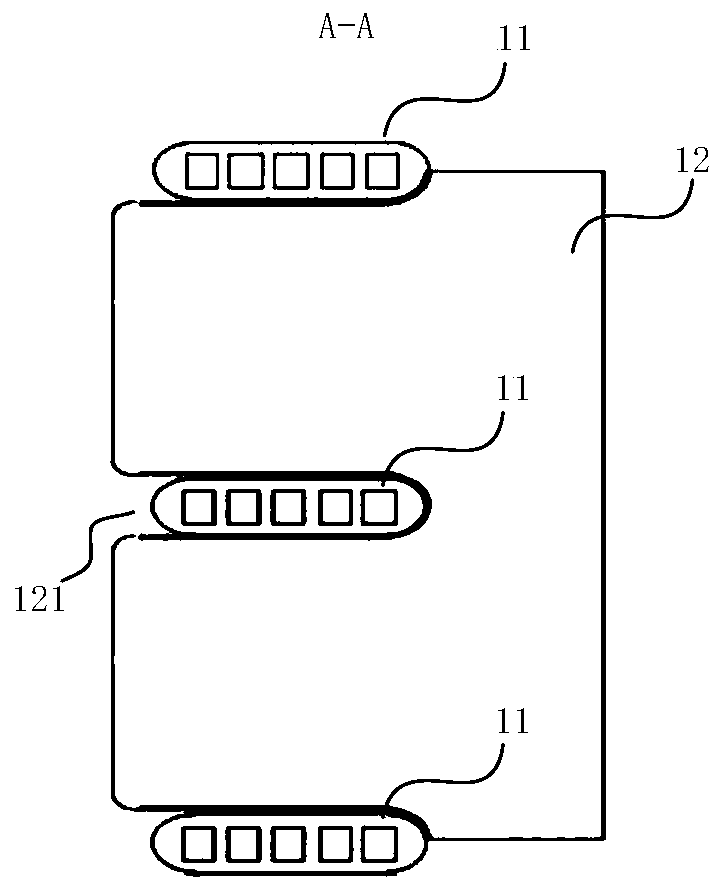

[0063] Embodiments of the present invention also provide a microchannel heat exchanger 40, such as Figure 11 As shown, the microchannel flat tube 30 is included, and the flat plate fin 20 provided in the above embodiment is also included. Wherein, the microchannel flat tube 30 passes through the microchannel flat tube installation groove 21 ( Figure 11 The micro-channel flat tube installation groove 21 is not shown in the figure, and the description about the micro-channel flat tube installation groove 21 can refer to the corresponding content of the first embodiment above).

[0064] Additionally, if Figure 11 As shown, in the microchannel heat exchanger 40, there are a plurality of flat fins 20, and the plurality of flat fins 20 are evenly spaced, and the microchannel flat tubes 30 are installed through the microchannel flat tubes of the plurality of flat fins 20 in turn. Groove 21, water guide plate 22 ( Figure 11 The water guide plate 22 is not shown in the figure, a...

Embodiment 3

[0068] An air conditioner, including a heat exchange system, wherein the heat exchange system is provided with the microchannel heat exchanger provided in the second aspect above.

[0069] In the refrigerator of the embodiment of the present invention, since the evaporator of the refrigeration cycle system is the above-mentioned microchannel heat exchanger assembly, the heat dissipation efficiency can be improved, the volume is small, the weight is light, the internal space of the refrigeration equipment is saved, and the problem of incomplete defrosting is solved. The problem.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com