Bearing arrangement for drive shaft of turbo-machine, and turbo-machine including such bearing arrangement

A technology of supporting structure and drive shaft, which is applied to components of pumping devices for elastic fluid, sliding contact bearings, machines/engines, etc., can solve problems such as increasing the manufacturing cost of turbo compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

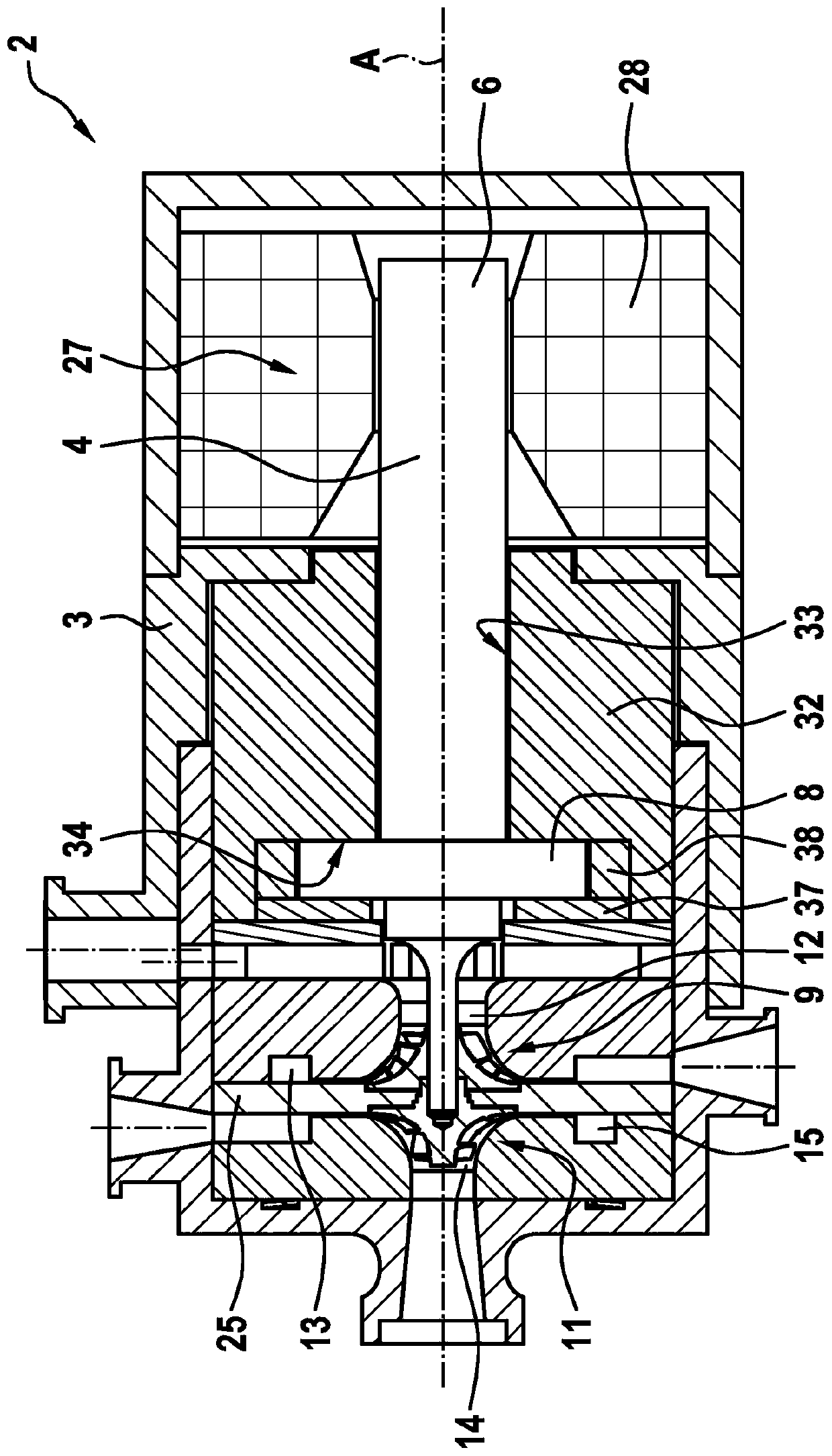

[0066] Figure 1 to Figure 3 A turbomachine 2 according to a first embodiment of the invention is represented, in particular a two-stage centrifugal turbocompressor.

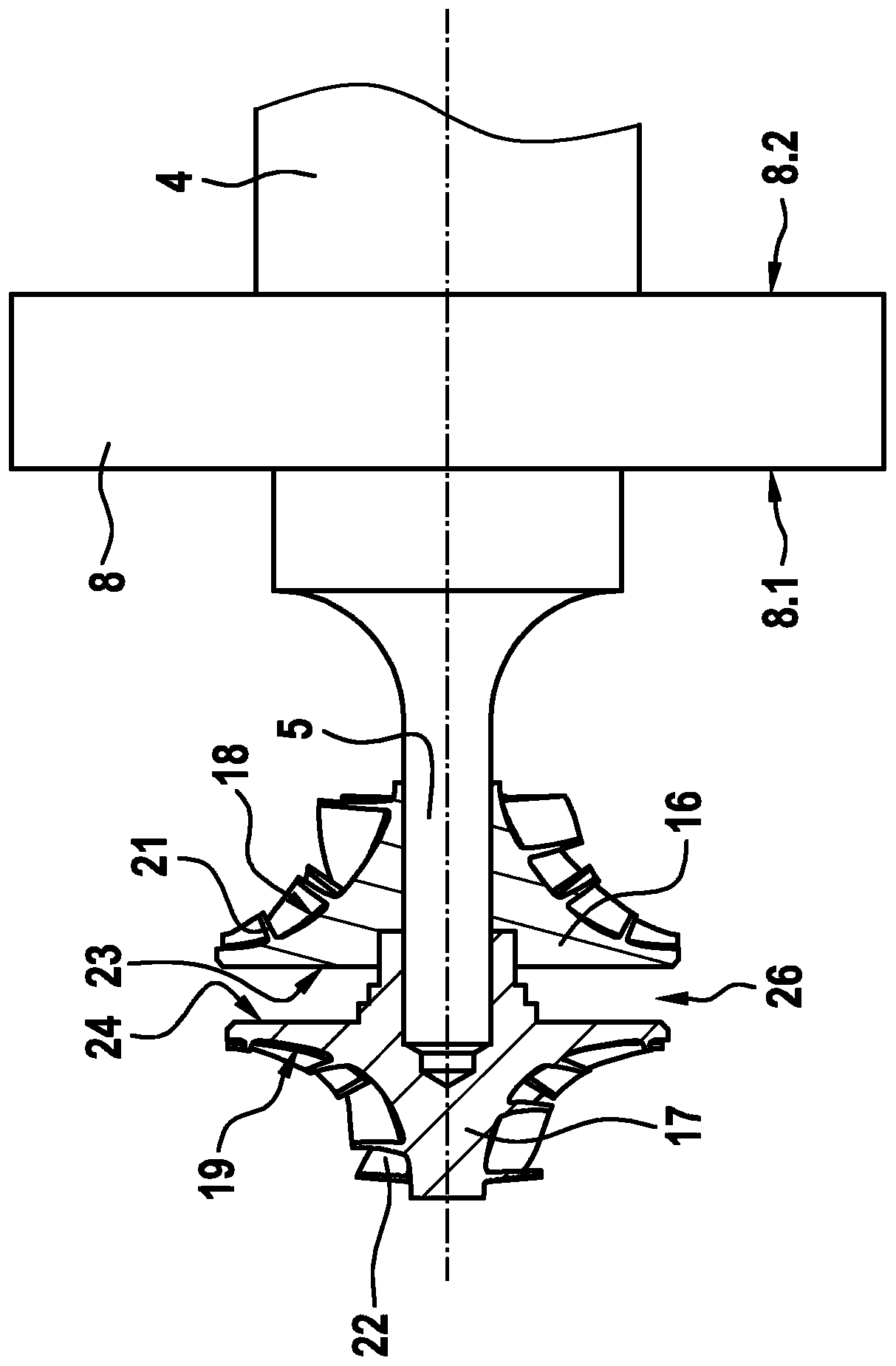

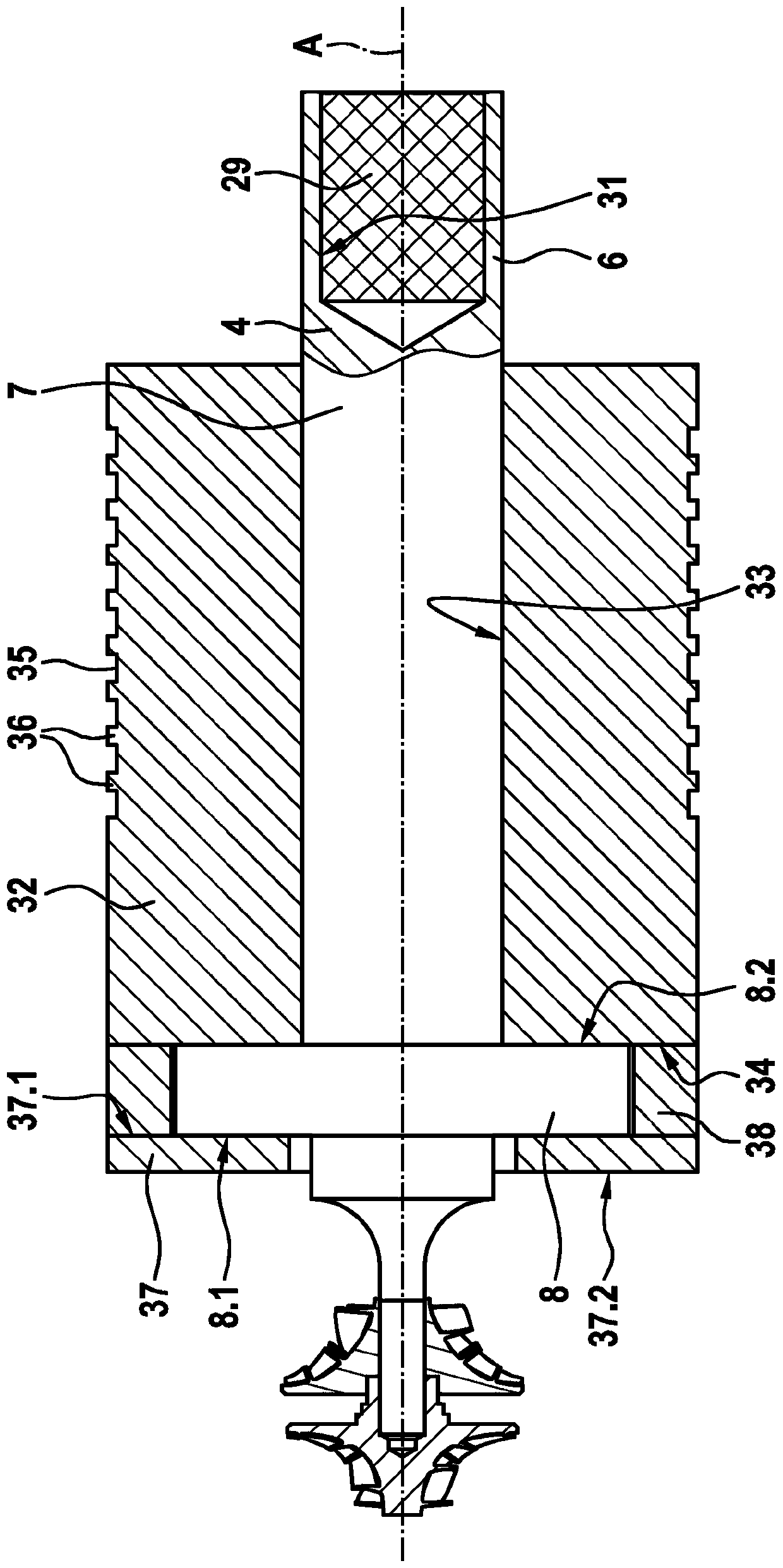

[0067] The turbine 2 comprises a housing 3 and a drive shaft 4 , which is rotatably arranged inside the housing 3 and extends along a longitudinal axis A. As shown in FIG. The drive shaft 4 includes an impeller portion 5 , a drive portion 6 opposite to the impeller portion 5 , and a bearing portion 7 arranged between the impeller portion 5 and the drive portion 6 .

[0068] The drive shaft 4 also comprises a radial thrust bearing member 8 , also referred to as a radial flange portion, which has the shape of a flat disc and extends radially outwards with respect to the bearing portion 7 . The radial thrust bearing member 8 has an outer diameter greater than that of the bearing portion 7 and comprises a first axial face 8.1 and a second axial face 8.2 opposite to the first axial face 8.1. The radial thrust suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com