Method to eliminate periodic noise from data collected by chromatography system

A chromatographic system, a technique for collecting data, applied in the field of eliminating periodic noise from data collected with a chromatographic system, capable of solving problems such as reduced pump pulse sensitivity, limited sensitivity pump pulse pickup, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Design instruments to inherently accommodate the effects of pump pulses

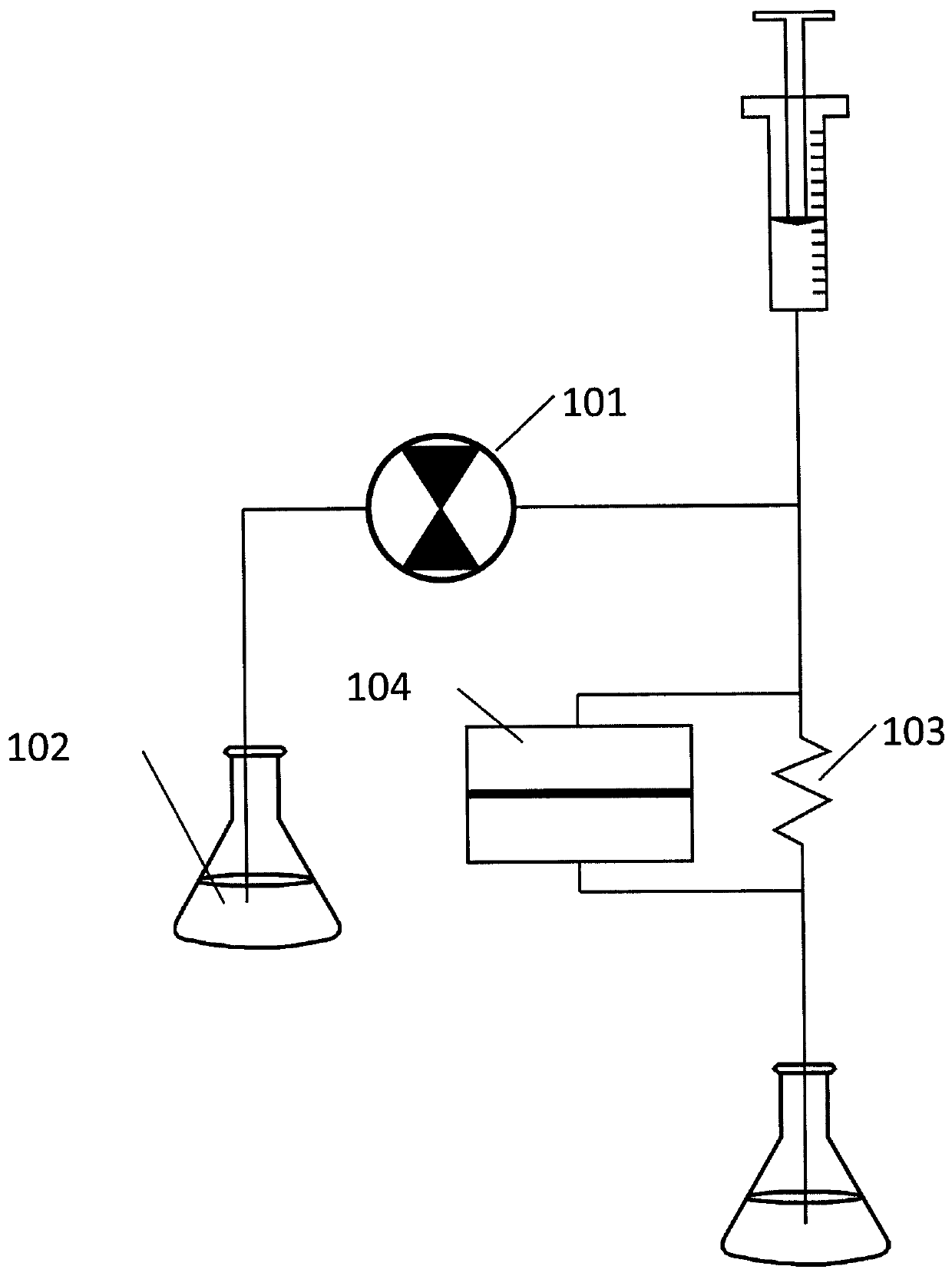

[0019] For certainty, an online viscometer may be considered to measure the change in viscosity of a liquid sample as the chromatographic peak passes the detector. Probably one of the simplest implementations is a single capillary design, examples of which are figure 1 shown. Pump 101 draws fluid from reservoir 102 and passes it through sensing capillary 103 . Differential transducer 104 measures the pressure across the capillary. The measured pressure is proportional to the flow rate and sample viscosity. If the solvent is first passed through the capillary and the baseline pressure P 0 , and subsequently inject the sample, the specific viscosity is simply

[0020] n sp (t)=P s (t) / P 0 -1 (1)

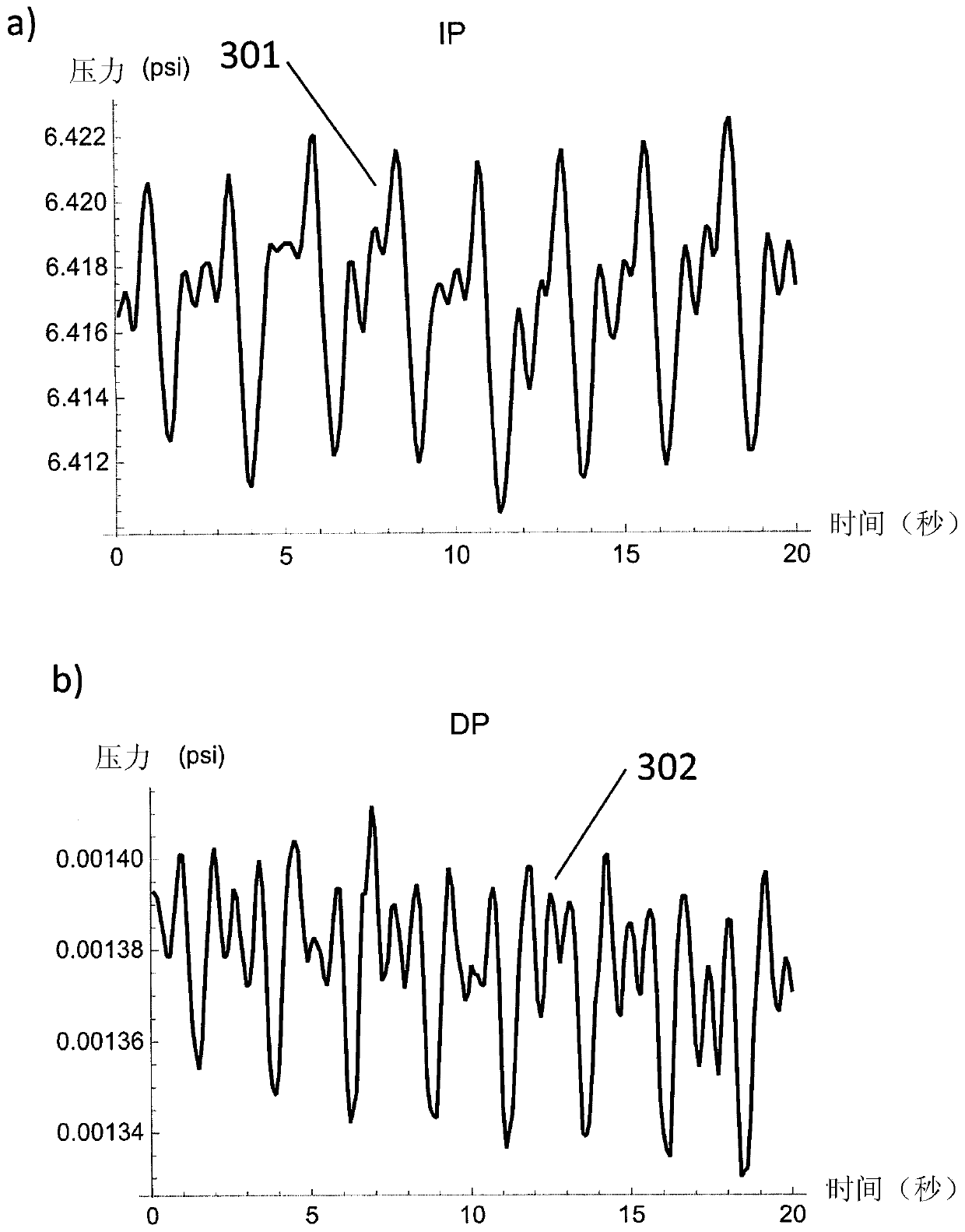

[0021] where P s (t) is the pressure of the sample. A key problem arising from such a flow system is that pump pulses generate a pressure signal that appears to be equivalent to a change in samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com