A kind of dog chew with hollow structure and preparation method thereof

A dog chew gum and hollow core technology, which is applied in the field of pet food, can solve the problems of inability to scrub teeth to a sufficient depth, inability to chew for a long time, and without product structural stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

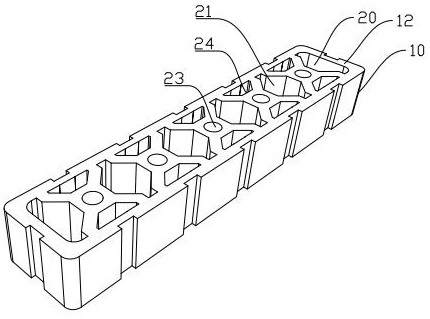

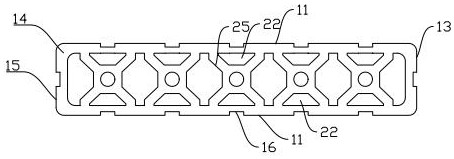

[0073] A sort of figure 1 The preparation method of shown dog chew comprises the following steps:

[0074] 1) Pour the edible raw materials into the silo: the edible raw materials include: 40 parts of amylose, 3 parts of edible adhesive, 2 parts of oil, 1 part of insoluble cellulose, 1 part of soluble dietary cellulose, moisturizing 2 parts of agent, 0.1 part of flavoring agent;

[0075] 2) Mixing of raw materials: Stir the materials in step 1) evenly at room temperature to obtain a mixed material;

[0076] 3) Maturation of raw materials: Stir and mature the mixed materials in a steam stirring pot, the amount of steam used in the food industry is twice the weight of the materials in step 1), and the curing time is 20 minutes;

[0077] 4) One-time extrusion molding: the above-mentioned materials are passed into the screw extruder, and under the action of the push of the screw groove, the mixed materials move forward in the axial direction and are transported to the metering e...

Embodiment 2

[0086] Adopt the same preparation process as in Example 1, wherein the edible raw material formula: 50 parts of amylose, 5 parts of edible adhesive, 3 parts of oil, 0.5 part of insoluble cellulose, 0.5 part of soluble dietary cellulose, 2 parts of humectant part, 0.4 part of flavoring agent. The coating includes the following components in parts by weight: 2.5 parts of vitamins, 2 parts of propolis extract, 2 parts of cranberry extract, and 0.5 part of calcium gluconate. The coating has the effect of repairing oral mucosa.

Embodiment 3

[0088]Adopt the same preparation process as in Example 1, wherein the edible raw material formula: 55 parts of amylose, 5.5 parts of edible adhesive, 5 parts of oil, 2 parts of insoluble cellulose, 1 part of soluble dietary cellulose, 3 parts of humectant part, 0.4 part of flavoring agent. The coating comprises the following components by weight: 2.5 parts of vitamins, 2 parts of propolis extract, 2 parts of cranberry extract and 0.8 part of calcium gluconate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com