A method for integral liquid-filled forming of large annular lip parts

A liquid-filled forming and annular technology, applied in the field of aerospace sheet metal forming, can solve the problems of uneven deformation, difficult to eliminate springback phenomenon, difficult to control precision, etc., to reduce uneven deformation, good development potential, and reduce local defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

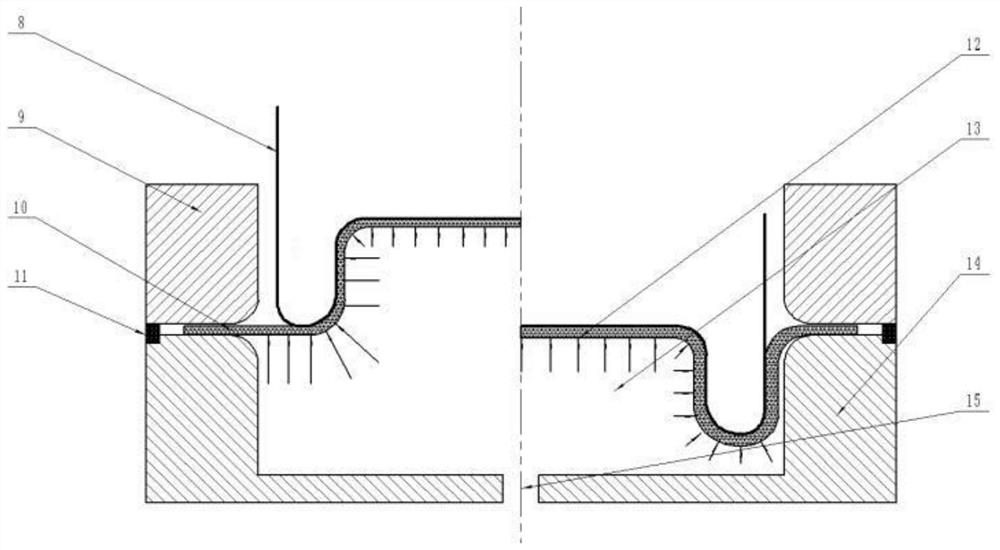

[0023] The following describes in detail the forming process of a typical annular lip piece formed by a method for forming a large-scale annular lip piece integrally liquid-filled forming method provided by the present invention with reference to the accompanying drawings and specific examples.

[0024] Such as Figure 1-Figure 3 As shown, the typical annular lip forming process provided by the present invention for the integral liquid filling forming method of large annular lip comprises the following steps:

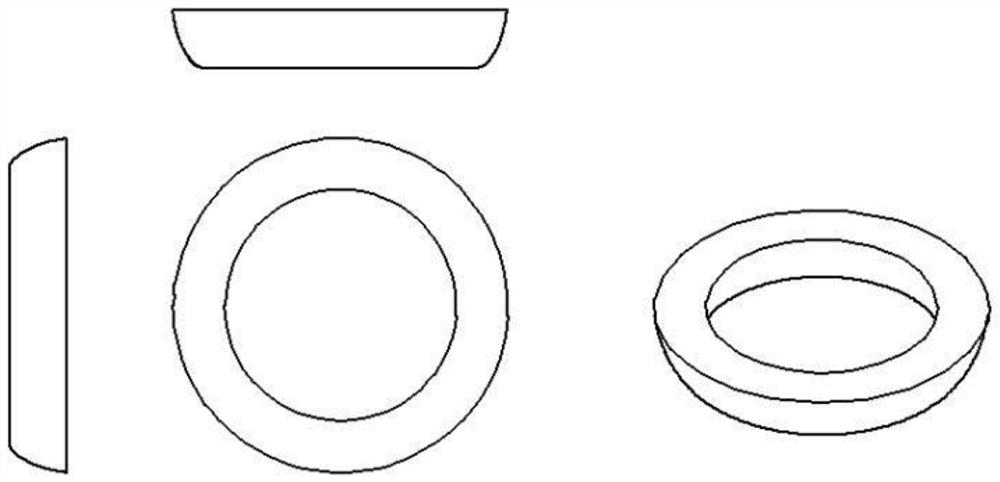

[0025] 1) The shape of a typical annular lip piece formed is as follows figure 1 shown;

[0026] 2) Clean the surface of each part before the mold assembly to ensure the surface quality of the product and the service life of the mold equipment;

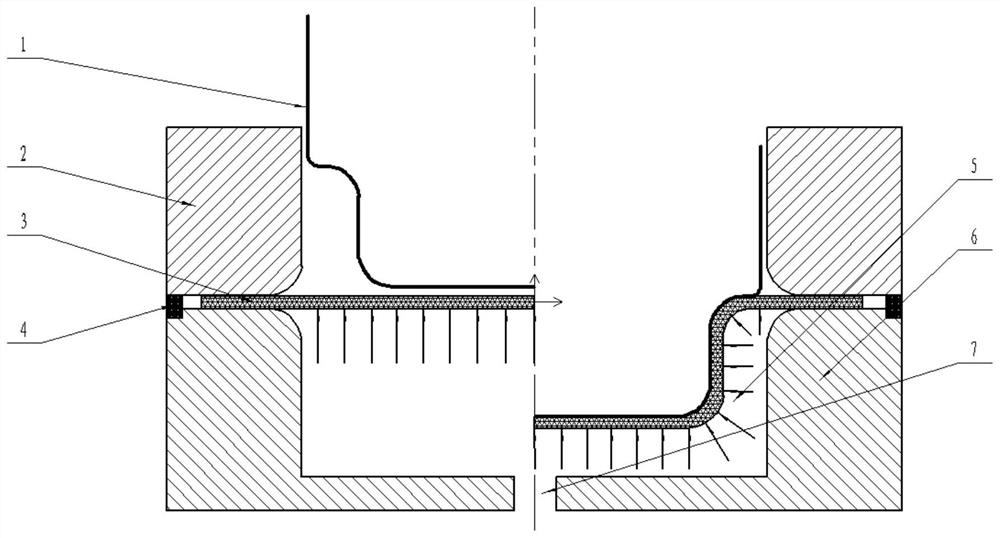

[0027] 3) if figure 2 Assembled transition forming die shown;

[0028] 4) Place the initial plate blank 3 on the die 6 of the transition forming die, position it through the stop block 4 of the transition forming die, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com