Multi-cutter mechanism and using method of high-efficiency precise cutting micro-structure and using method

A technology of precision cutting and fine structure, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc. It can solve the problems of increasing the number of mold splicing, not being able to cut large molds, and affecting product quality, so as to reduce the number of splicing , avoiding the offset of the cutter head and improving the cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

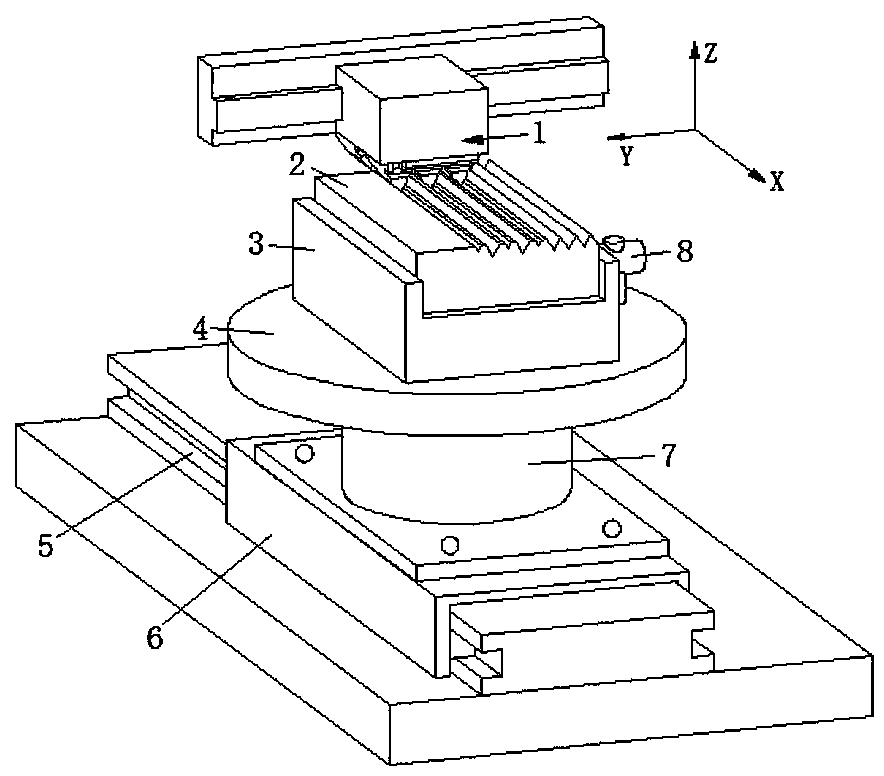

[0041] Such as Figure 4 As shown, the tool assembly 1 includes a first tool seat 11a, a tool mounting base 12, and a cutting head 13 fixed on the tool mounting base 12, the first tool seat 11a is fixed on the feed guide rail of the engraving machine tool, and the tool There are two installation bases 12, and the two tool installation bases 12 are fixed on the bottom of the first tool holder 11a;

Embodiment 2

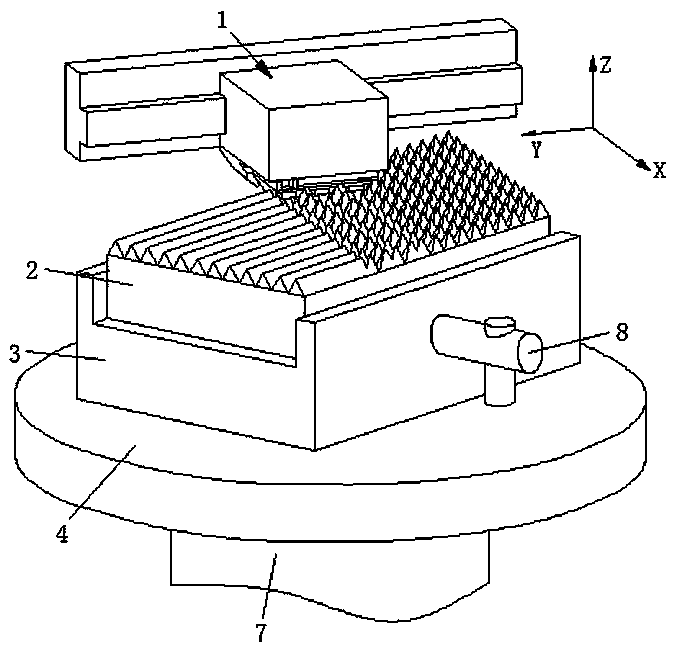

[0043] Such as Figure 5 As shown, the knife assembly 1 also includes a second knife seat 11b, the second knife seat 11b is welded to the front surface wall of the first knife seat 11a, and the structure of the second knife seat 11b is the same as that of the first knife seat 11a;

[0044] In summary, both the first tool seat 11a and the second tool seat 11b are hydraulic lifting devices, and the hydraulic drive can effectively realize the movement of the tool mounting base 12 and the cutting head 13, thereby facilitating the adjustment of the Z-axis feed amount; Among them, the cutter assembly 1 proposed in Embodiment 1 has a relatively small structure, and can be effectively applied to engraving machine tools with a small movable range.

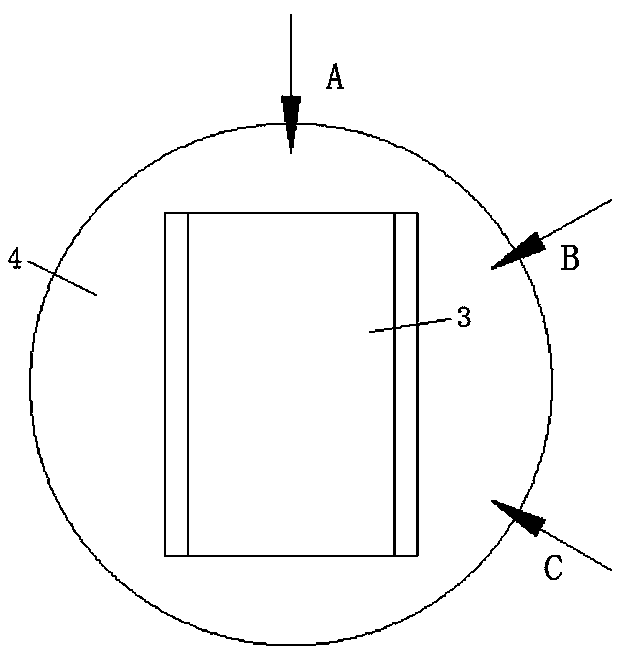

[0045] The workpiece assembly includes a workpiece driving device and a workpiece holder 3 installed on the workpiece driving device. The inside of the workpiece holder 3 is engaged with a workpiece 2. The top surface of the workpiece 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com