Special tool clamp for friction stir welding of complex welding seam aluminum alloy

A friction stir welding and tooling technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of affecting the quality and work efficiency of the weld, easy deformation of the workpiece, and inability to perform continuous welding, so as to improve the weld quality. Quality and process efficiency, the effect of continuous weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

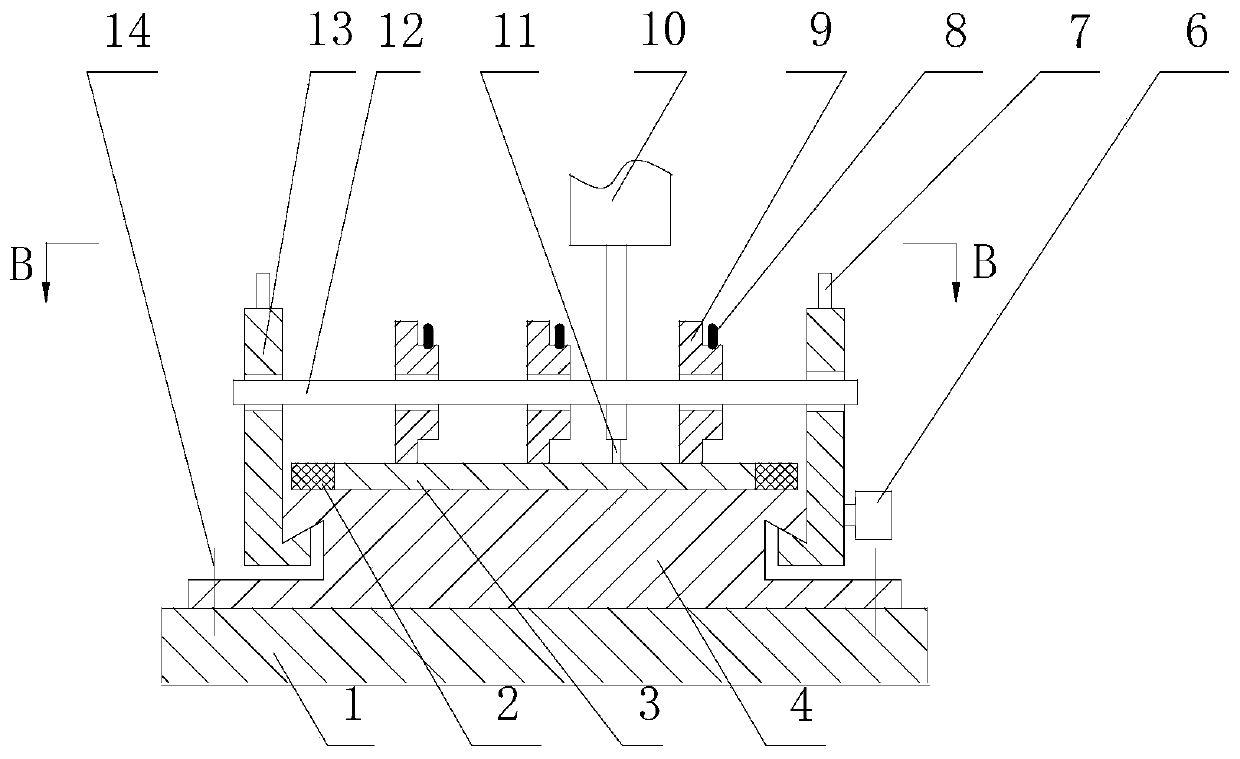

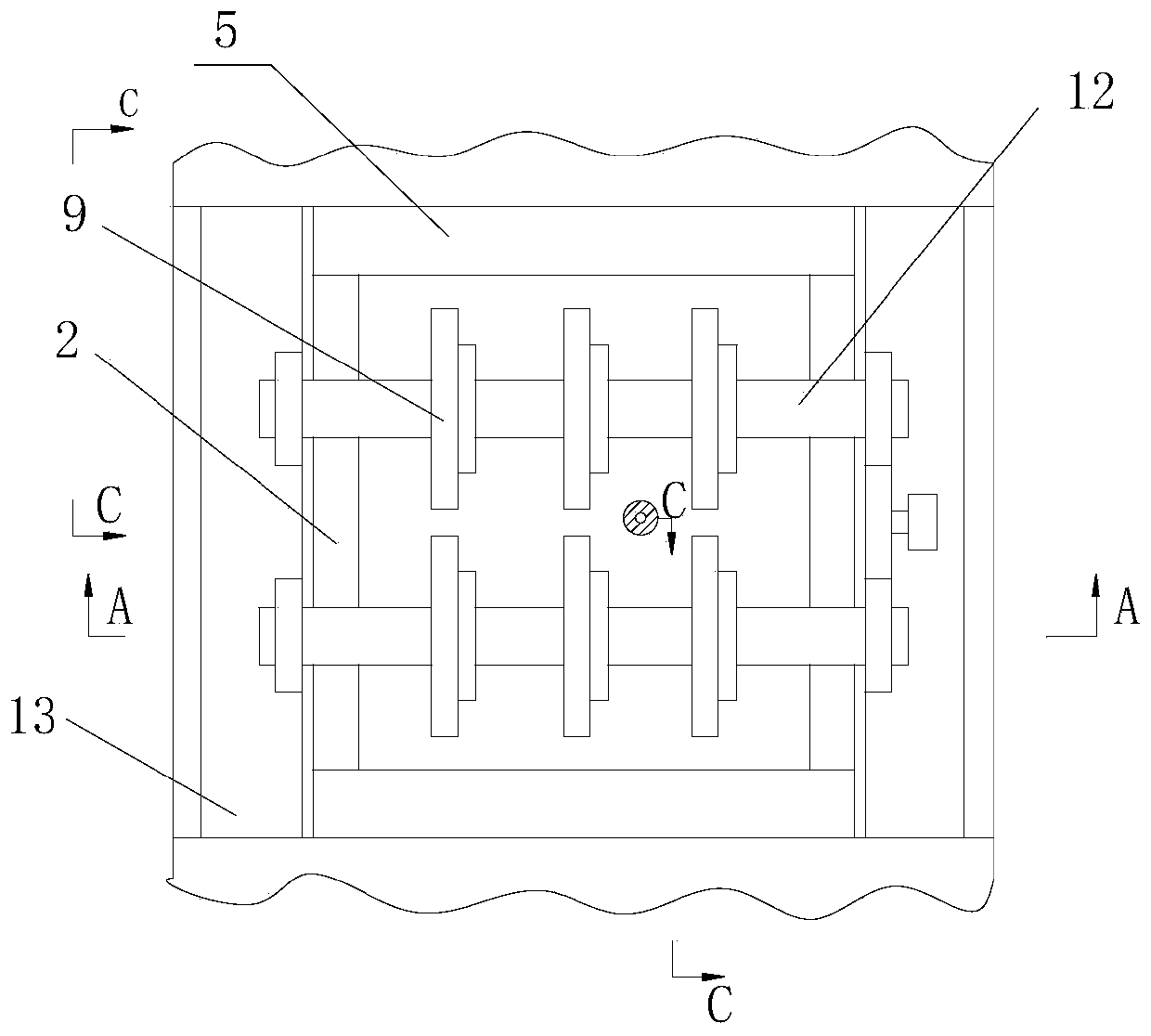

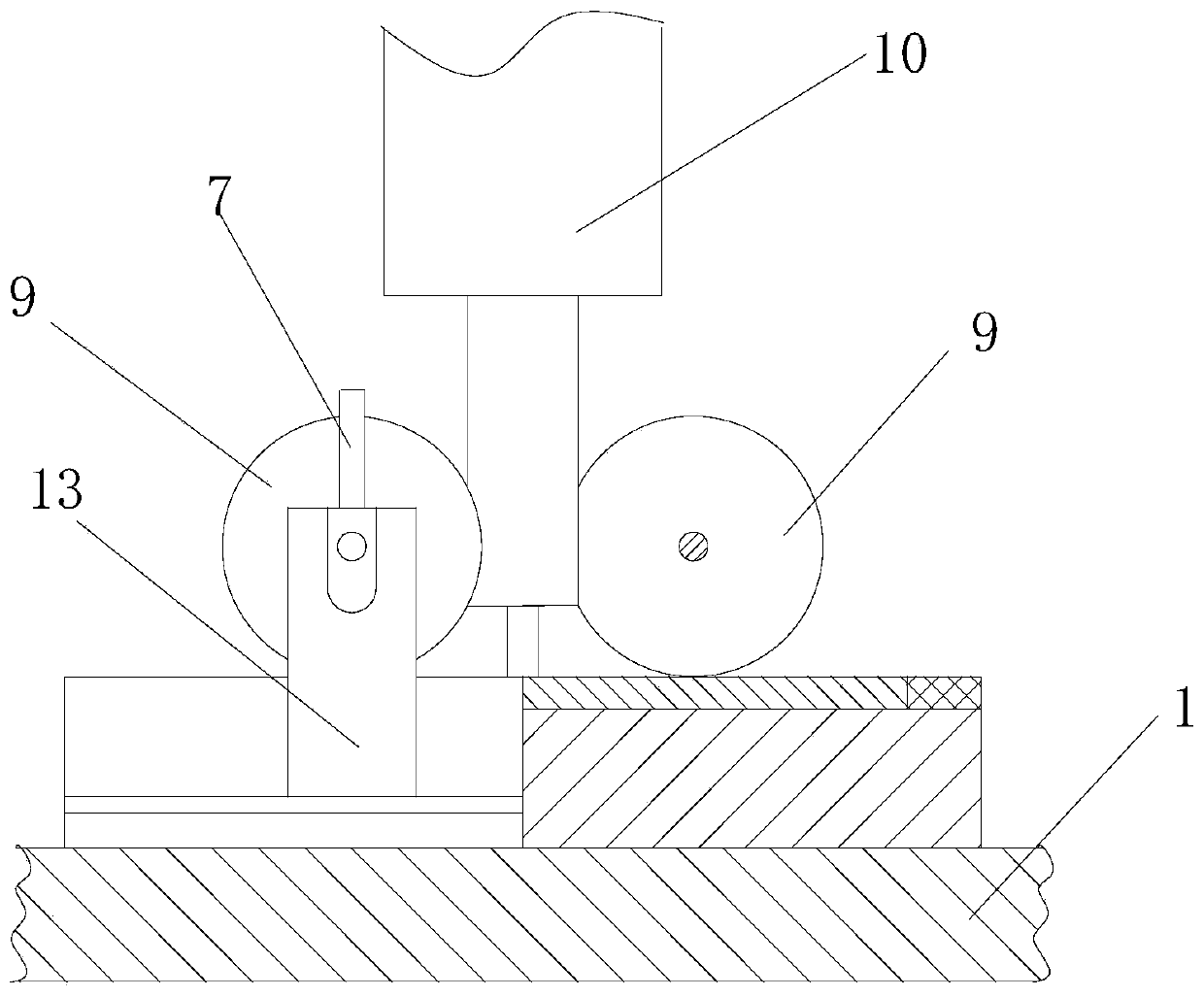

[0024] The fixture base 4 is fixedly connected with the friction stir welding workbench 1 through the fixture fixing bolt 14, and is welded on the workpiece 3 and placed on the fixture base 4 and fixed by the limit stopper 2 and the fixed block 5 to avoid being The welding part 3 moves in the plane direction of the workbench, the pressure wheel 9 rolls on the wheel shaft 12 and the workpiece 3 to be welded, the position of the pressure wheel on the wheel shaft is adjustable, and after the position is adjusted properly, it is fixed by the pressure wheel fixing bolt 8 , both sides of the wheel shaft rotate on the wheel shaft support 13, the pressing force of the pressure wheel on the wheel shaft is manually adjusted by the wheel shaft adjustment bolt 7 bearing seat, the bearing seat can move up and down in the wheel shaft support chute, and the pressing force can be adjusted. Usually, the axle support chute at the bottom of the design bearing housing is provided with a spring, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com