Processing and installation technology of a cutter bridge frame of a cutter suction dredger

A cutter suction dredger and installation process technology, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. The tool bridge cannot be processed in the workshop, etc., to achieve the effect of high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

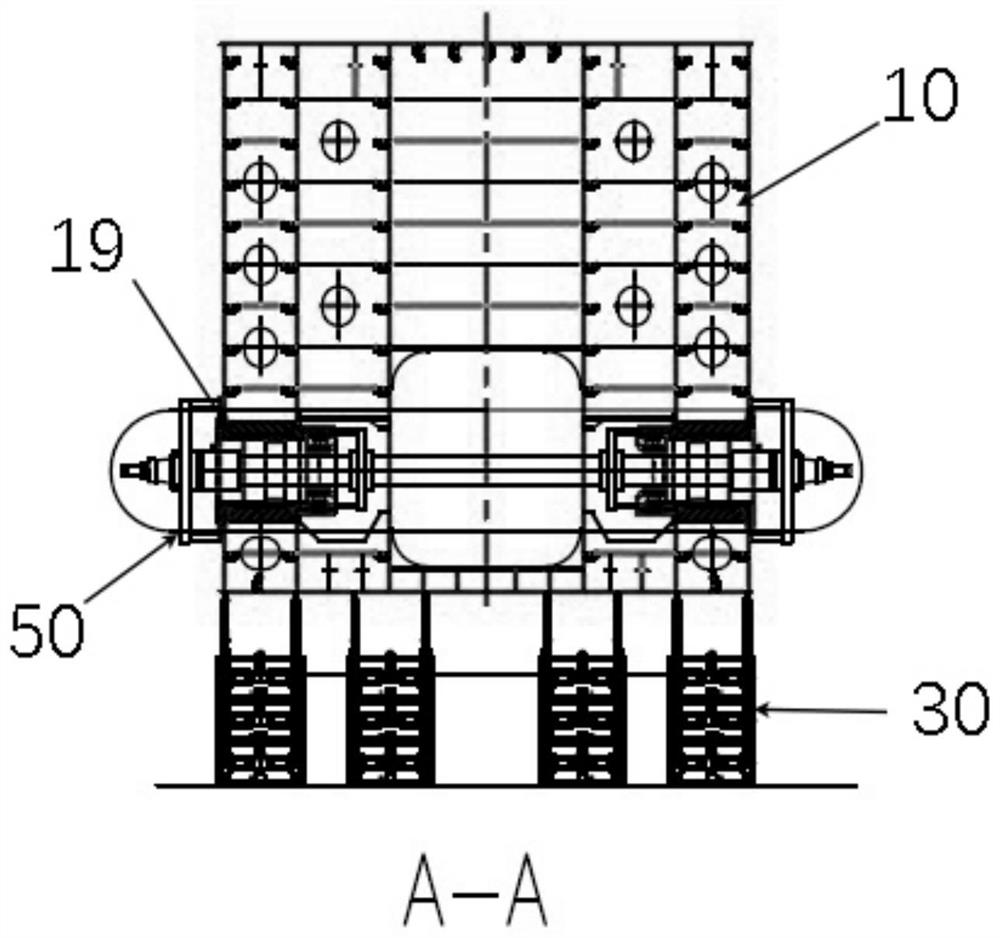

[0055] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0056]The cutter bridge of a cutter suction dredger related to the present invention is a large-scale equipment used to control the work of the cutter head, and is arranged on the dredger for dredging operations.

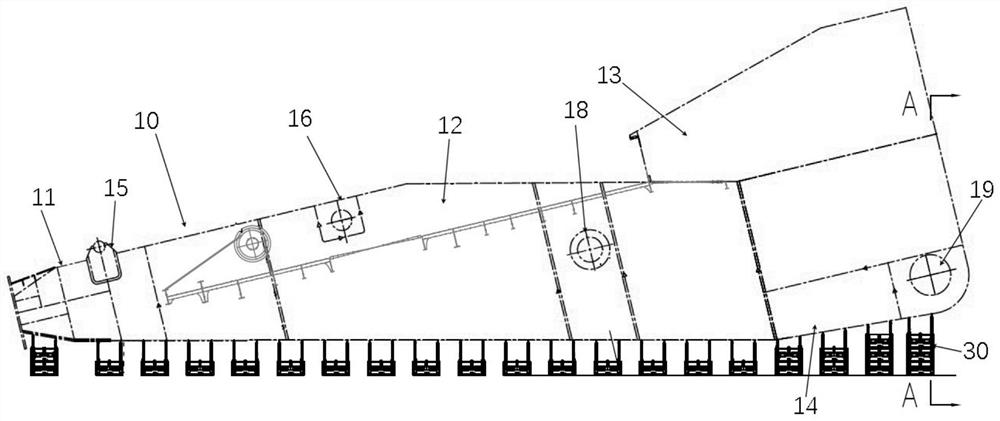

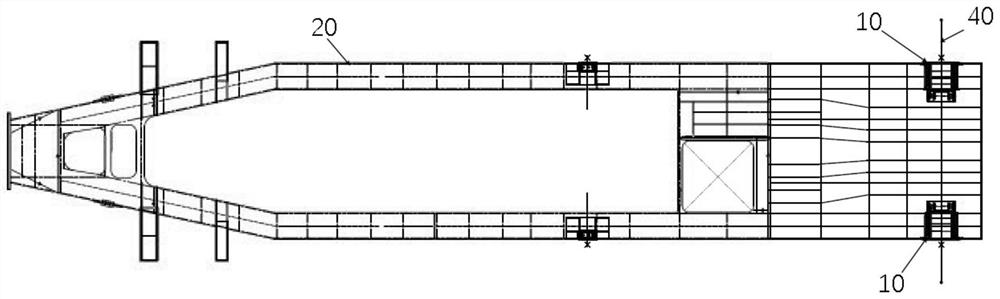

[0057] like figure 1 As shown, the manufacturing process of the reamer bridge 10: the embodiment of the present invention will be described by taking the specifications of the reamer bridge as an example: the length of the steel structure is about 41360mm, the width is 9300mm, the width of the bridge body is 7550mm, and the height is 13440mm. According to its characteristics, the reamer bridge is divided into 4 large sections, which are the head of the reamer bridge 11, the main part of the reamer bridge 12, the tail of the reamer bridge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com