Turn-down and turn-up device of full-steel giant tire building machine

A technology of tire building machine and front and back packaging, which is applied to tires, other household appliances, household appliances, etc. It can solve the problems of high requirements, complexity, and failure to meet the process requirements, so as to achieve high automation of the production process, improve production efficiency, The effect of smooth and fast action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

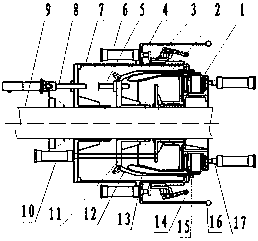

[0012] Such as figure 1 Shown: Auxiliary turn-back positioning mechanism 1, capsule turn-back mechanism 2, push apex mechanism 3, capsule push mechanism 4, hydraulic cylinder one 5, cylinder one 6, sleeve mechanism 7, hydraulic cylinder two 8, spindle 9 , hydraulic cylinder three 10, finger-shaped positive bag mechanism 11, finger-shaped sheet 12, air bag 13, pressing rubber roller 14, buckle ring 15, pushing capsule ejector pin 16, cylinder two 17.

[0013] The front and back wrapping device of the all-steel giant tire building machine of the present invention includes a main shaft 9, a finger-shaped front-and-back wrapping mechanism 11 which is sleeved on the main shaft 9 and can slide axially on the main shaft, a capsule turn-up wrapping mechanism 2 and a sleeve Mechanism 7, the front end of the sleeve mechanism 7 is provided with a buckle ring 15, which is characterized in that: the sleeve mechanism 5 is provided with a pushing triangle driven by the cylinder one 6 that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com