Bridge crane automatic control device

An automatic control device, bridge crane technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of operator injury, etc., to achieve the effect of ensuring precise control, ensuring speed and stability, and improving automation control rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

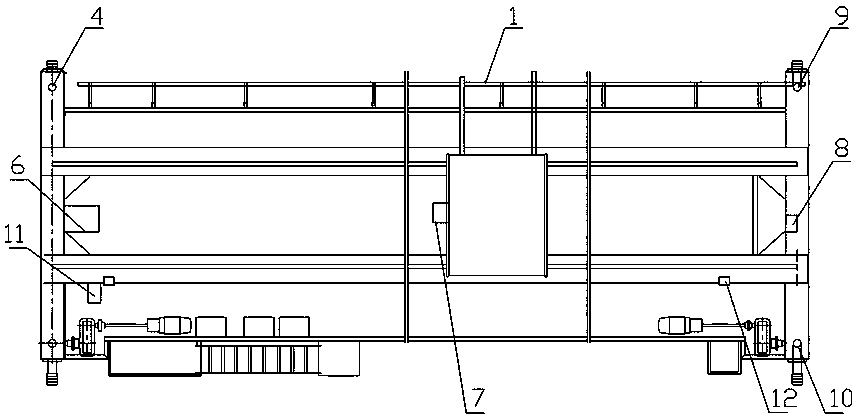

[0017] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 2 For example, the positional relationship of front, rear, top, bottom, left, right, etc. is determined according to the layout direction of the drawings in the description.

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

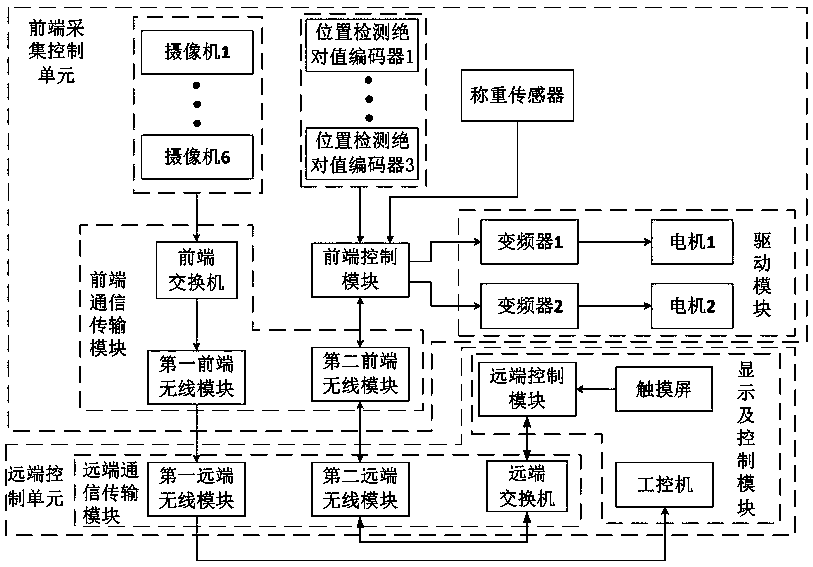

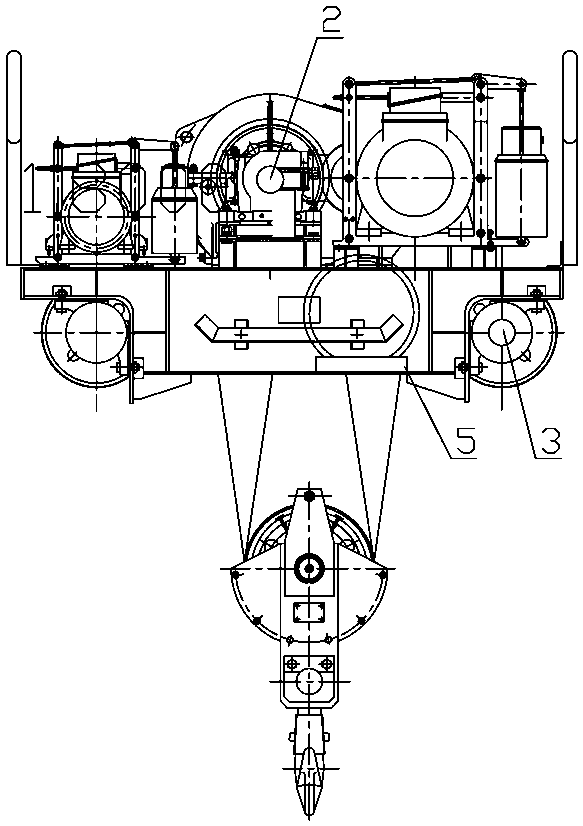

[0019] as attached figure 1 , 2 As shown in , 3, the bridge crane automatic control device includes a remote control unit and a front-end acquisition control unit, the front-end acquisition control unit includes a front-end control module and a front-end communication tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com