Cleaning pool structure with oil-water separation function

A technology for oil-water separation and tank cleaning, applied in liquid separation, separation methods, multi-stage water/sewage treatment, etc., can solve the problem of inability to distinguish oil pollution, and achieve the effect of oil-water separation and oil storage, beautiful appearance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

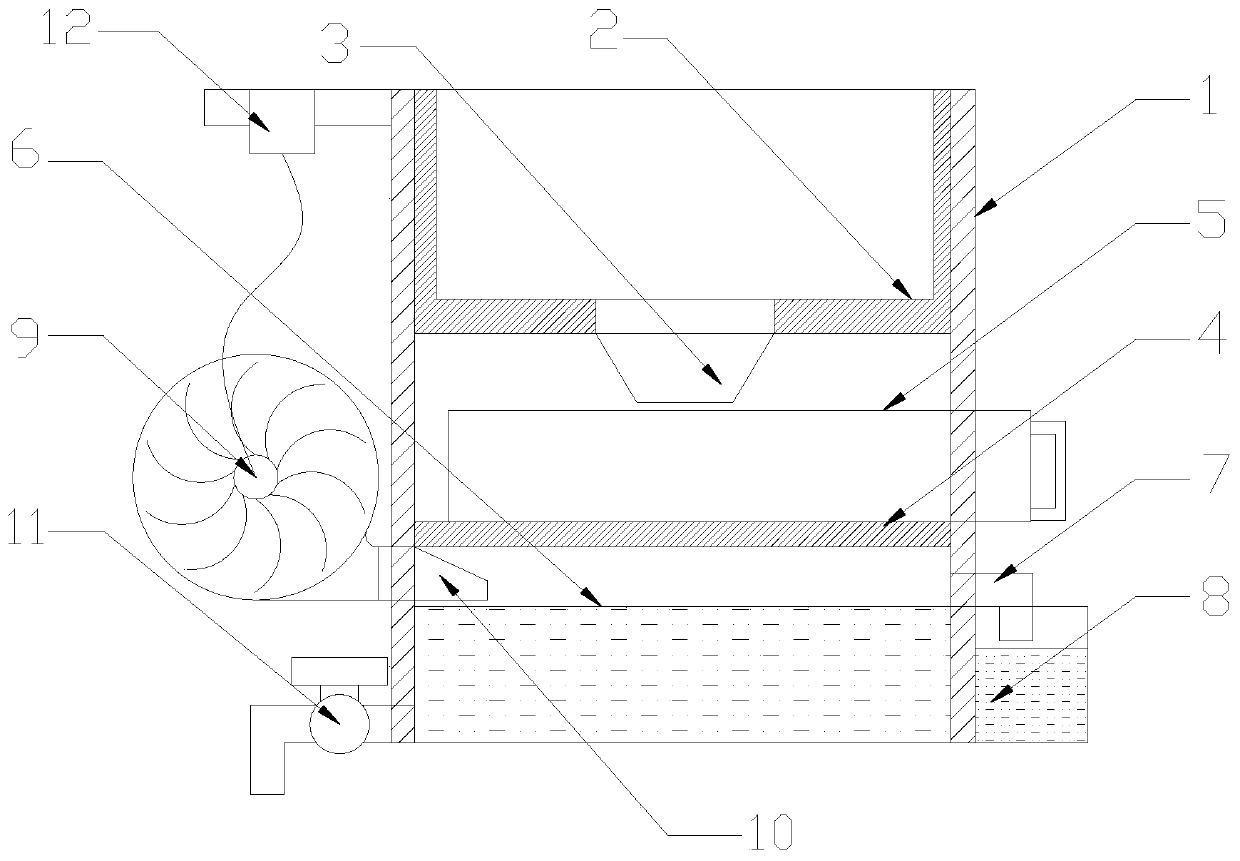

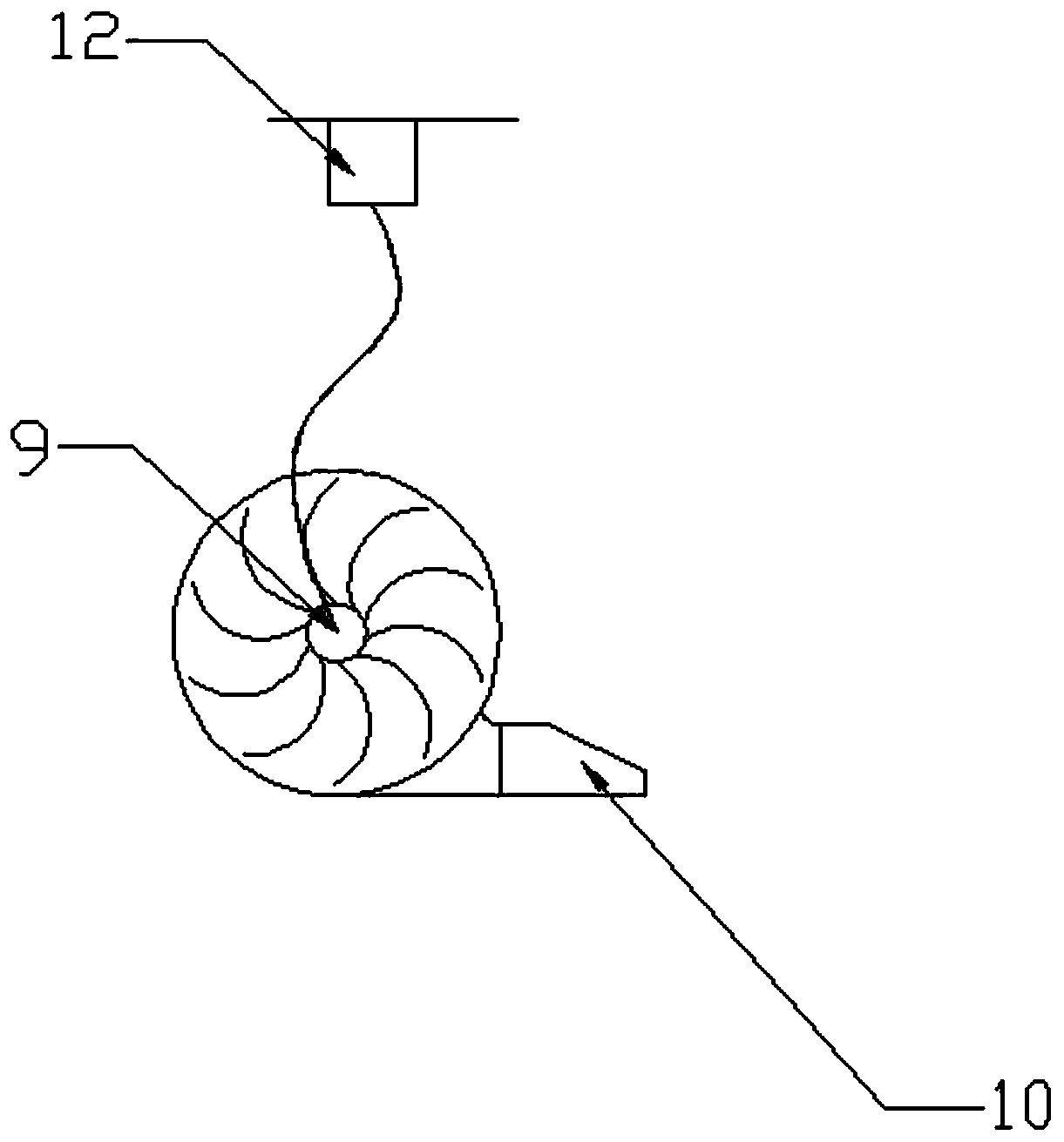

[0019] Such as Figure 1-3 As shown, the present invention provides a cleaning tank structure with oil-water separation function, including a rectangular support 1, a cleaning tank 2, a plug valve 3, a drawer funnel 5, an oil and dirt separation tank 6, an oil storage bottle 8 and a blower 9, rectangular A cleaning tank 2 is installed on the top support of the bracket 1, and a plug valve 3 is installed at the bottom of the inner cavity of the cleaning tank 2. The middle part of the rectangular bracket 1 is fitted with a drawer-type funnel 5 through two side guide rails 4. The bottom of the valve 3 is facing the top of the drawer funnel 5, the drawer funnel 5 is used to intercept solid slag, the bottom of the rectangular support 1 is fixedly provided with an oil separation tank 6, and one side of the oil separation tank 6 top is equipped with an outlet The oil port 7 and the bottom of the oil outlet 7 are provided with an oil storage bottle 8, and the other side of the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com