Laser cladding device capable of recycling and reusing reflected light

A technology of laser cladding and reflected light, which is applied in the coating process and coating of metal materials, can solve the problems of limited size of cladding workpieces, low laser utilization rate, hindering the development of laser cladding technology, etc., and achieve the reduction of equipment harm to the human body, expand the promotion and application field, and increase the effect of laser utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

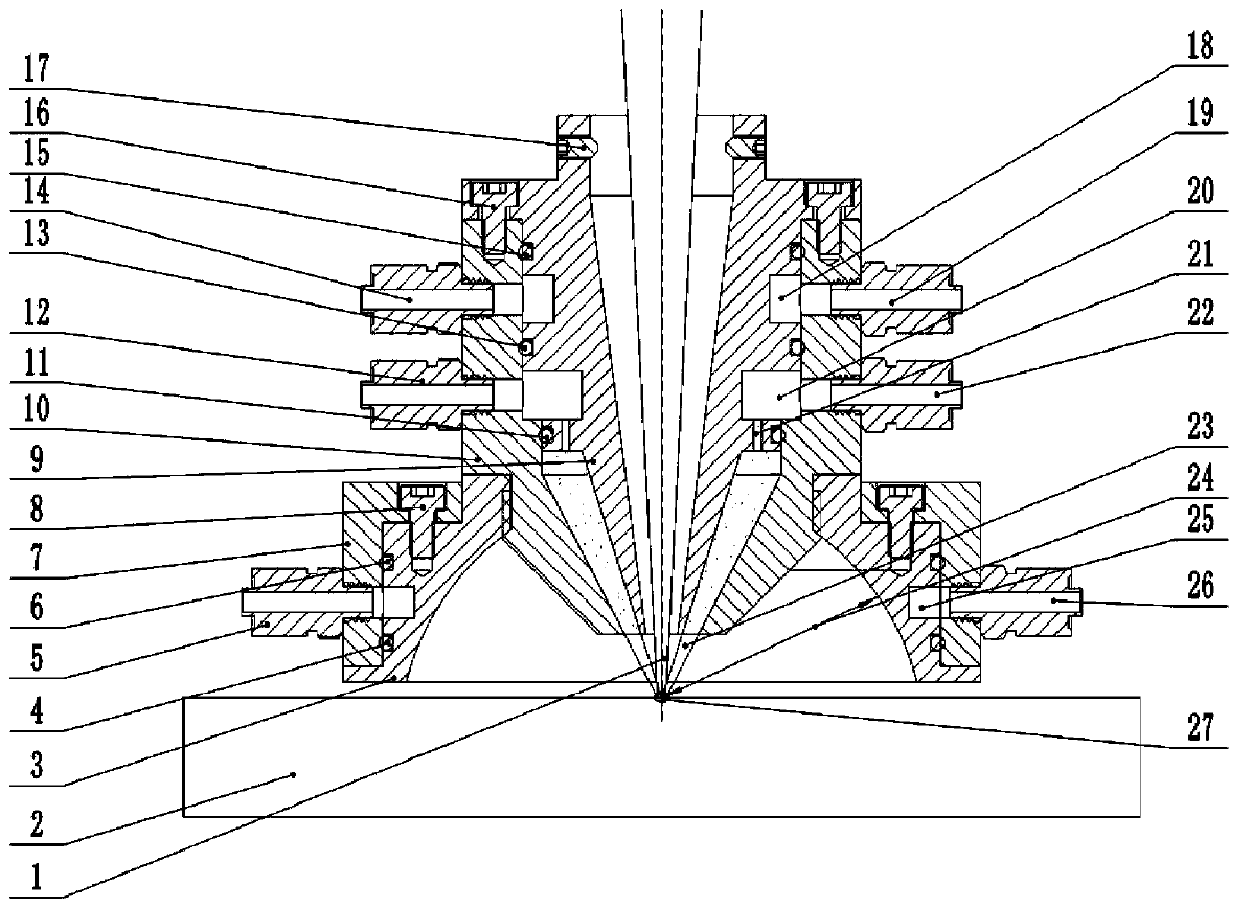

[0038] In this embodiment, the laser cladding device of the present invention is used to clad and remanufacture the surface of the valve workpiece. When the laser beam 1 and the powder beam from the laser system are focused on the surface of the workpiece 2 to form a molten pool 26, the laser beam 1 has a part After being reflected, the reflected light 24 reaches the surface of the spherical mirror of the reflector 3, is reflected back along the original path and refocuses with the laser beam 1, the powder beam, and the workpiece 2, thereby realizing the recovery of the reflected laser light, increasing the utilization rate of the laser light and reducing the reflected laser light Injury to equipment and human body.

[0039] The laser cladding device used in this example is as described in the detailed description, wherein the reflector 3 and the reflector cover 7 are connected by the first fixing bolt 8 and the first sealing ring 4 and the second sealing ring 6 are installed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com