Guided wave radar level meter

A technology of guided wave radar and level meter, which is applied in the direction of liquid/fluid solid measurement, engine lubrication, instruments, etc. It can solve the problems of inconvenient installation of wave radar meter, achieve improved stability, simple device structure, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

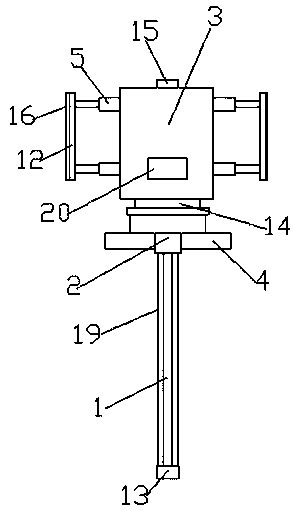

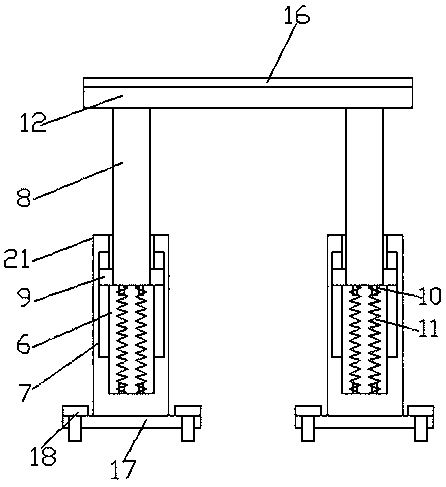

[0028] see Figure 1-2 , a guided wave radar level gauge according to an embodiment of the present invention includes a probe 1, a probe 13 is connected to the bottom end of the probe 1, and a connecting block 2 is provided at the top of the probe 1, and the The connection block 2 is provided with a meter head 3, and a signal processing chamber 14 is arranged below the meter head 3, and the signal processing chamber 14 is connected to the probe 1 through the connection block 2, and the outside of the connection block 2 A fixed plate 4 is provided, and installation devices 5 are provided on both sides of the meter head 3, and the installation device 5 includes two first installation rods 21 in number, and cavities are provided in the first installation rods 21 6. Both sides of the inner wall of the cavity 6 are provided with chute 7, the cavity 6 is provided with a second installation rod 8, and the second installation rod 8 is located on both sides of one end of the cavity 6 ...

Embodiment 2

[0031] Such as Figure 1-2 As shown, the meter head 3 is provided with a cable installation port 15, which is convenient for cable installation; the installation plate 12 is provided with an elastic gasket 16, which can improve the stability of the installation; There is a fixed plate 17, and the fixed plate 17 is symmetrically provided with threaded nails 18, and the fixed plate 17 is detachably connected with the meter head 3 through the threaded nails 18, so as to facilitate the installation and disassembly of the first installation rod 21; A protective case 19 is provided outside the probe 1, and the protective case 19 is fixedly installed on the connection block 2, which can protect the probe 1; a data transmitter 20 is provided on the meter head 3, The data transmitter 20 is electrically connected with an external data receiver, so as to transmit the detected data.

[0032] In order to facilitate the understanding of the above-mentioned technical solution of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com