Transparent material internal defect detection method based on time-sharing exposure image synthesis

A transparent material and internal defect technology, applied in the field of defect detection, can solve problems such as urgent needs, failure to meet AOI manual requirements, and difficult debugging, so as to simplify the overall logic design, shorten the overall running time, and improve the defect detection rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

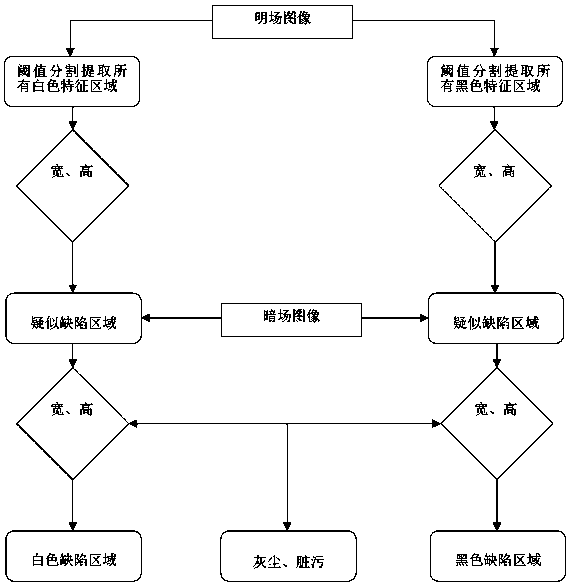

[0032] Such as figure 1 As shown, a method for detecting internal defects of transparent materials based on time-sharing exposure image synthesis is to perform bright-field irradiation on the transparent material under test during transmission, and the camera uses time-sharing exposure to obtain bright-field images of the surface of the test object ( Such as figure 2 as shown); Dark field irradiation is carried out on the object to be measured which is made of transparent material in transmission, and the camera adopts the method of time-sharing exposure to obtain the dark field image of the surface of the object to be measured (such as image 3 shown); set bright and dark field parameters, as shown in the table below:

[0033] parameter bright field dark field image width (pixels) 8192 8192 Image height (pixels) 20000 20000 Segmentation threshold (grayscale) 100 50

[0034] Perform threshold segmentation on the bright field image at a...

Embodiment 2

[0036] Such as Figure 6 As shown, a method for detecting internal defects of transparent materials based on time-sharing exposure image synthesis is to perform bright-field irradiation on the transparent material under test during transmission, and the camera uses time-sharing exposure to obtain bright-field images of the surface of the test object ( Such as Figure 7 as shown); semi-dark field irradiation is performed on the test object of transparent material in transmission, and the camera adopts the method of time-sharing exposure to obtain the semi-dark field image of the surface of the test object (such as Figure 8 as shown); Dark field irradiation is carried out on the object to be measured which is made of transparent material in transmission, and the camera adopts the method of time-sharing exposure to obtain the dark field image of the surface of the object to be measured (such as Figure 9 shown); set bright, semi-dark field and dark field parameters, as shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com