Gas overflow detection device and paraffin scarping equipment

The technology of a detection device and a gas detector, which is applied in the field of petroleum wax scraping, can solve the problems of difficult hydrogen sulfide, alarm and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

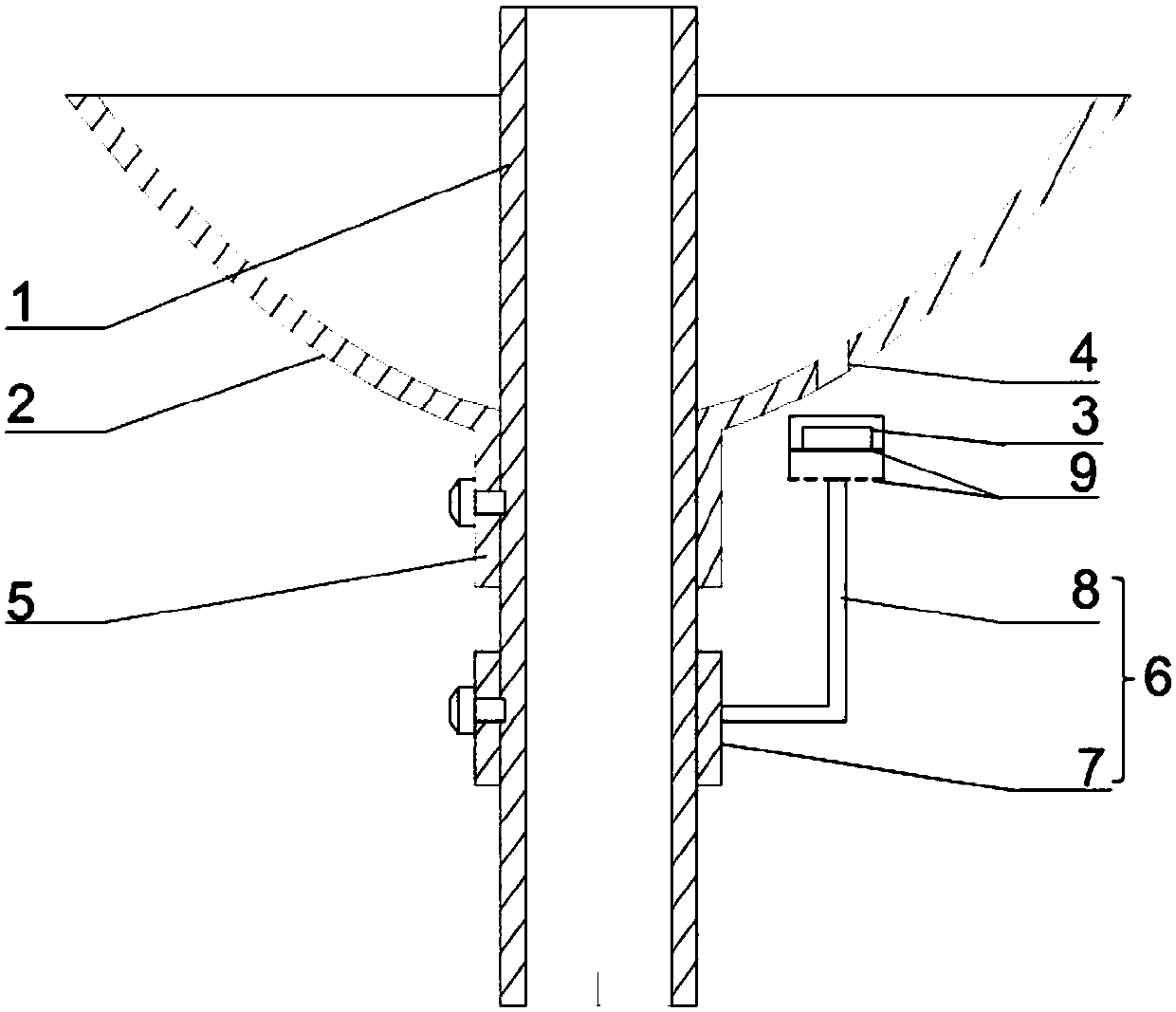

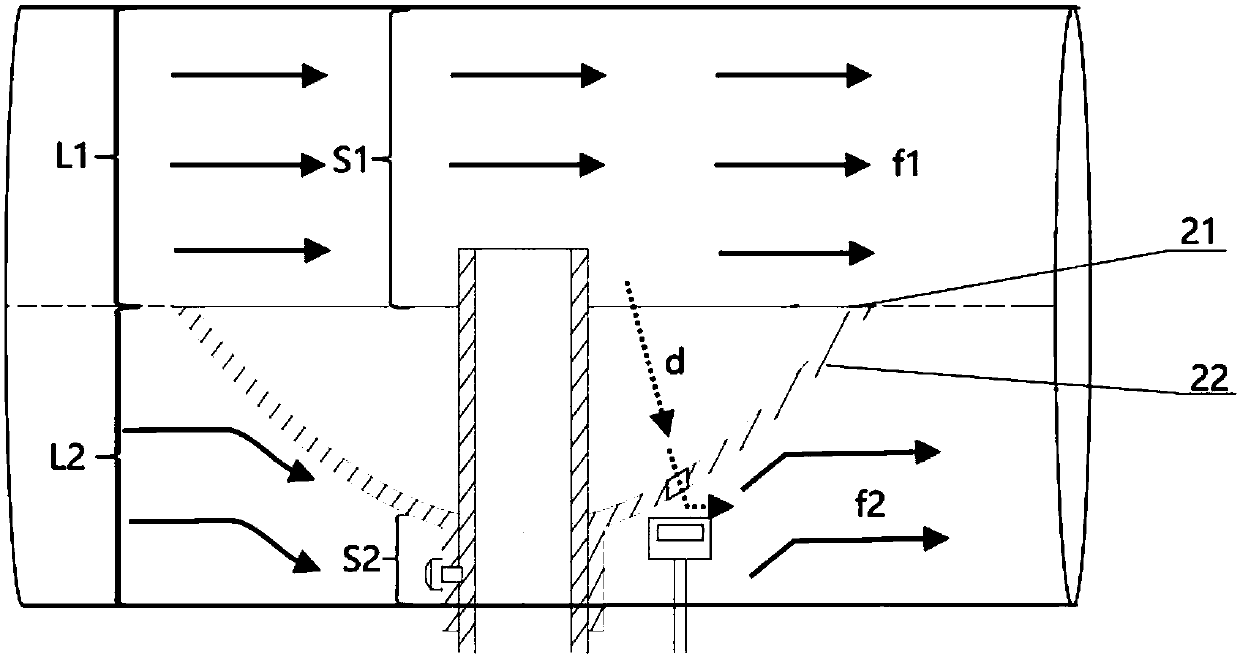

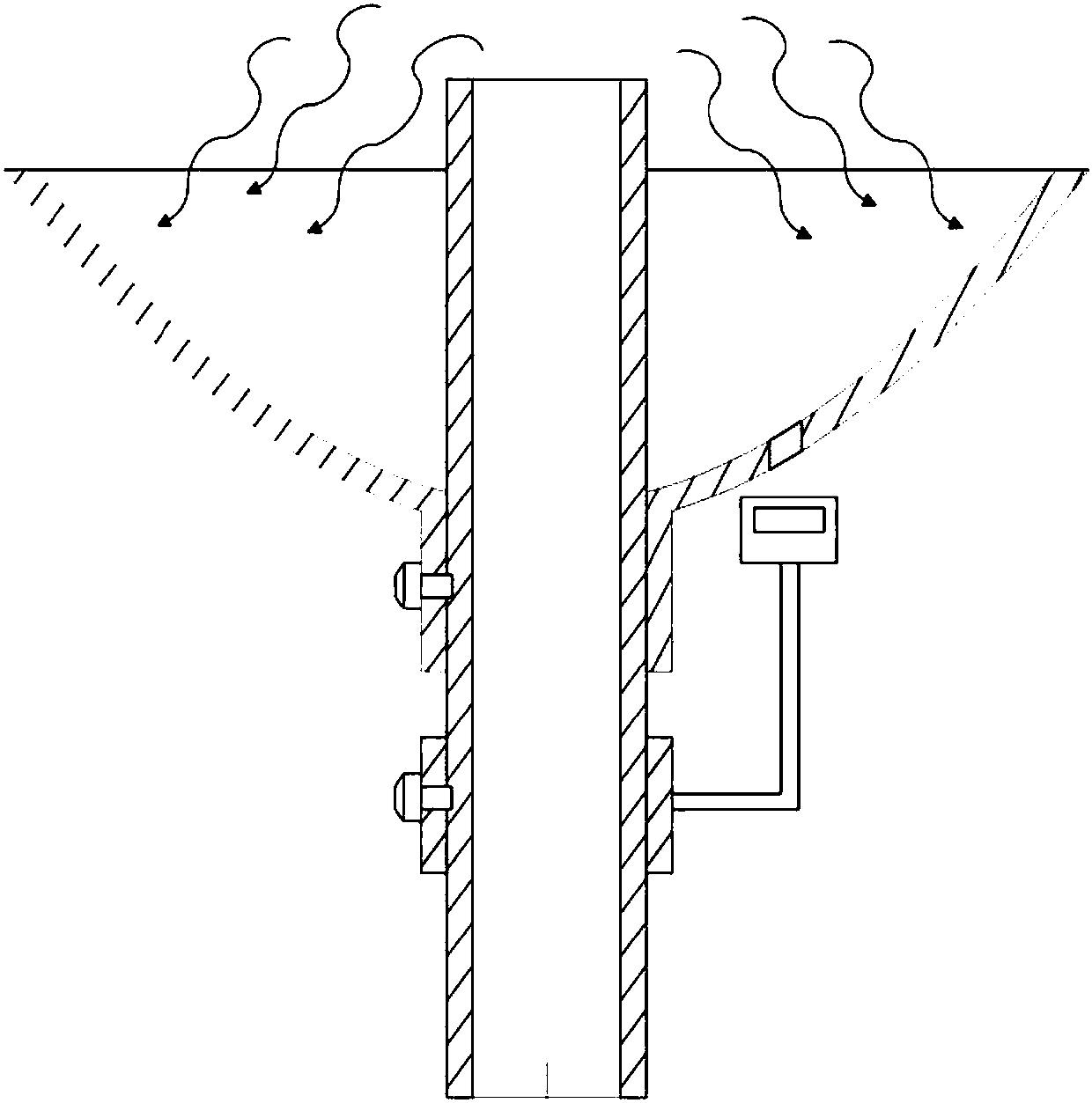

[0032] figure 1 It is a schematic structural diagram of the gas overflow detection device provided in Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the diversion principle of the gas overflow detection device provided in Embodiment 1 of the present invention, image 3 It is a schematic diagram of the gas flow of the gas overflow detection device provided in Embodiment 1 of the present invention when there is no wind or weak wind, Figure 4 It is a schematic diagram of the gas flow of the gas overflow detection device provided by Embodiment 1 of the present invention when the wind is strong. Such as Figure 1-4 As shown, the gas overflow detection device provided in this embodiment is applied to the blowout preventer 1 of the wax scraping equipment, specifically, as figure 1 As shown, it includes a shroud 2 and a gas detector 3, wherein,

[0033] The gas detector 3 is located outside the nozzle 2, and the nozzle 2 is set on the nozzle 1, and ...

Embodiment 2

[0068] Figure 5 It is a schematic structural diagram of the gas overflow detection device provided by Embodiment 2 of the present invention. The gas overflow detection device provided in this embodiment is applied to the blowout preventer 1 of wax scraping equipment, specifically, as Figure 5 As shown, it includes a shroud 2 and a gas detector 3, wherein,

[0069] The gas detector 3 is located outside the nozzle 2, and the nozzle 2 is set on the nozzle 1, and the top area of the nozzle 1 is covered. Generally, in the process of mechanical wax removal, the wax scraping equipment relies on the nozzle 1 to enter Inside the oil well, the top of the blowout preventer 1 relies on rubber to wrap the steel wire into it for sealing. In order to detect whether the sealing effect is good or not, and to prevent the overflow of toxic gas hydrogen sulfide caused by poor sealing effect, in this embodiment, the nozzle cover 2 The cover is arranged at the sealing port of the top area of ...

Embodiment 3

[0095] This embodiment provides a kind of wax scraping equipment, wherein, the wax scraping equipment at least includes a blowout preventer 1 and any gas overflow detection device in the above-mentioned embodiments, and the gas overflow detection device is arranged on the top of the blowout preventer 1 to ensure the prevention of blowout. All the gas overflowing from the sealing port of the nozzle 1 flows to the hydrogen sulfide detector through the shroud 2 of the gas overflow detection device. Wherein, other components of the wax scraping equipment can refer to the existing wax scraping structure, which will not be described in detail in this embodiment, and the specific structure and working principle of the gas overflow detection device have been described in detail in the first embodiment above. I won't repeat them here.

[0096] In this embodiment, the gas overflow detection device provided for detecting the overflow of hydrogen sulfide gas at the blowout preventer in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com