Automatic adhesive tape fixed-point binding device and binding method thereof

An adhesive tape and automatic technology, applied in the direction of electrical components, manufacturing wiring harnesses, circuits, etc., can solve the problems of large number of tooling plates, low production efficiency, and high labor intensity of workers, so as to achieve stable and reliable wrapping quality, improve production efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

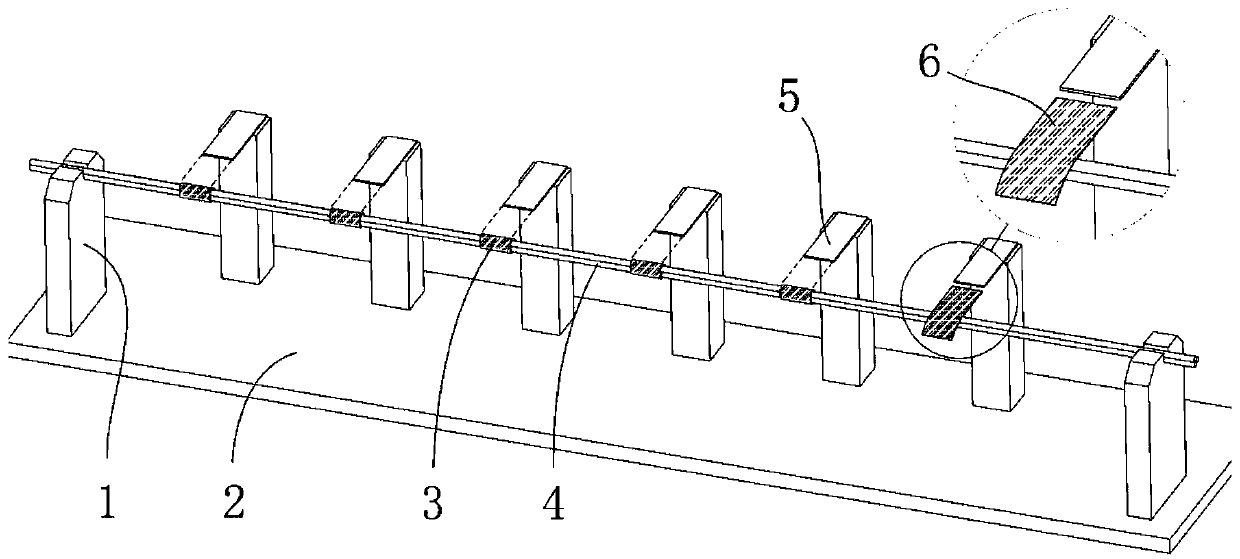

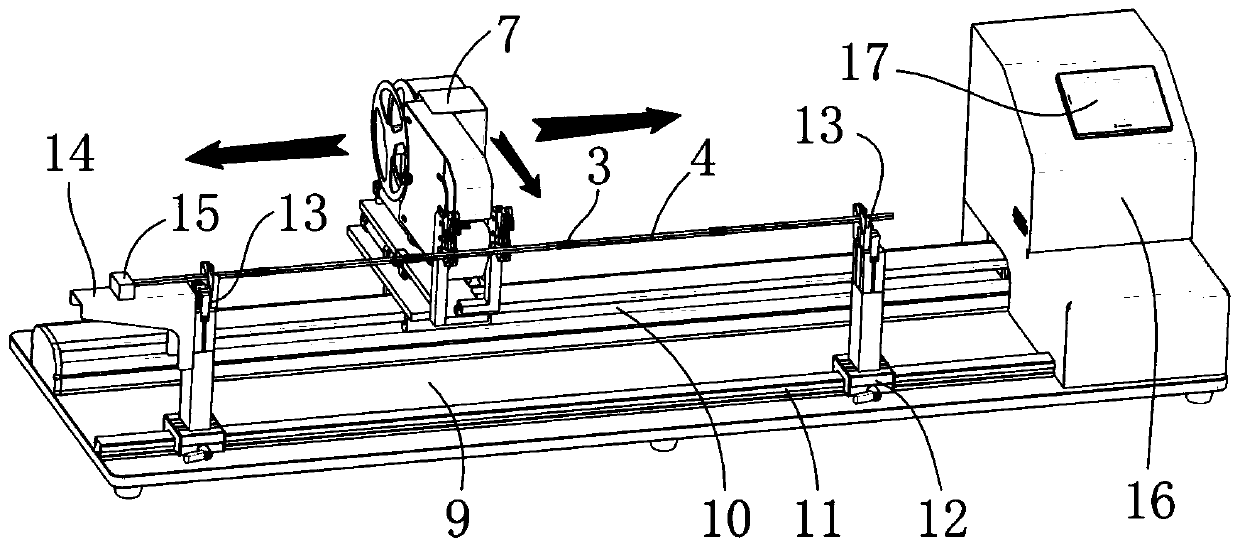

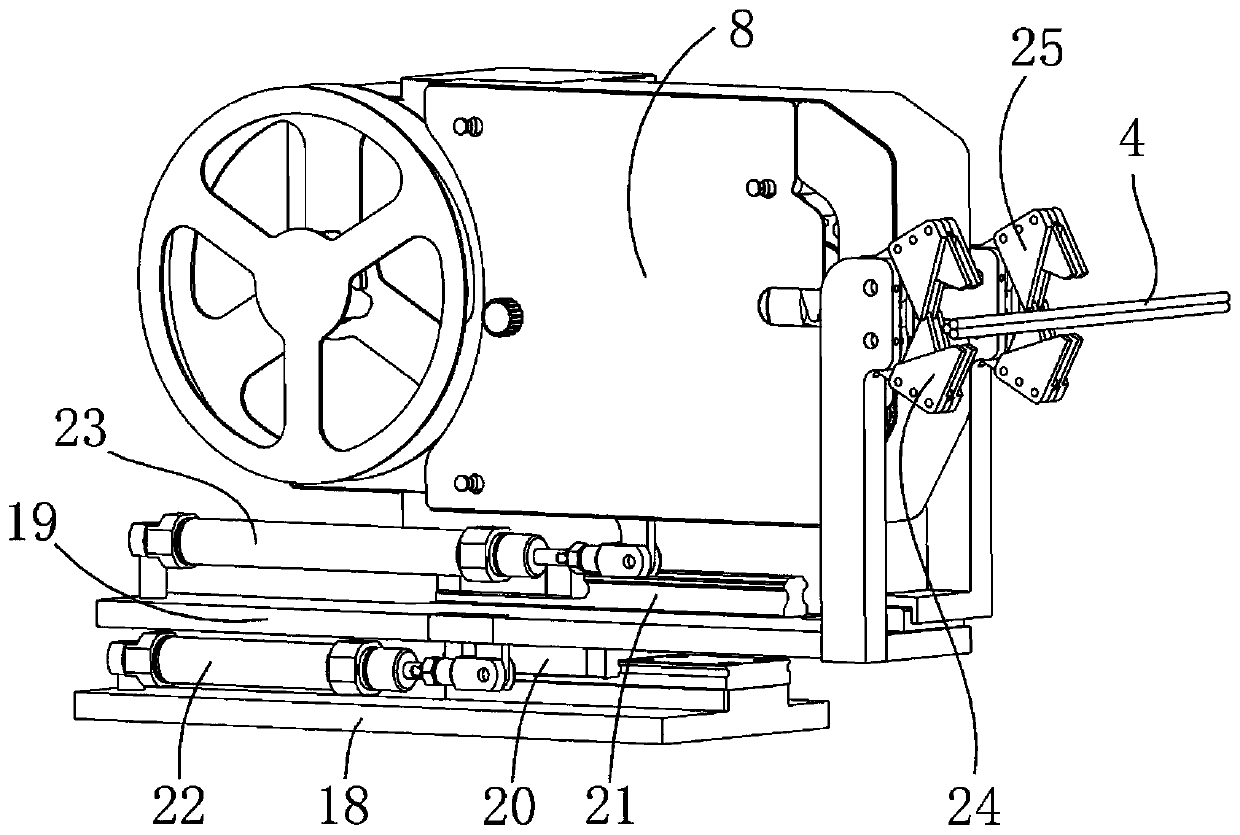

[0045] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

[0046] like figure 2 , image 3 As shown, the main components of the automatic adhesive tape fixed-point bandaging equipment of the present invention include: an automatic rubber-covering module 7, a first linear drive mechanism, a base 9, a linear guide rail 11, a lockable slider 12, and an automatic harness clamping mechanism 13. Wire harness positioning seat 14, wire harness positioning slider 15, control box 16, touch screen 17. The automatic encapsulation module 7 includes an automatic encapsulation machine head 8, a module base 18, a machine head base 19, a left clamping assembly 24, a right clamping assembly 25, a second linear drive mechanism and a third linear drive mechanism. Wherein the first linear drive mechanism, the second linear drive mechanism and the third linear drive mechanism can theoretically enable any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com