Soft package lithium battery assembly tab PCB and process thereof

A soft-packed lithium battery and PCB board technology, applied in the direction of lithium batteries, electrical components assembling printed circuits, assembling battery machines, etc., can solve problems such as failure to meet design requirements, and achieve convenient after-sales maintenance, increased volume, and convenient assembly process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

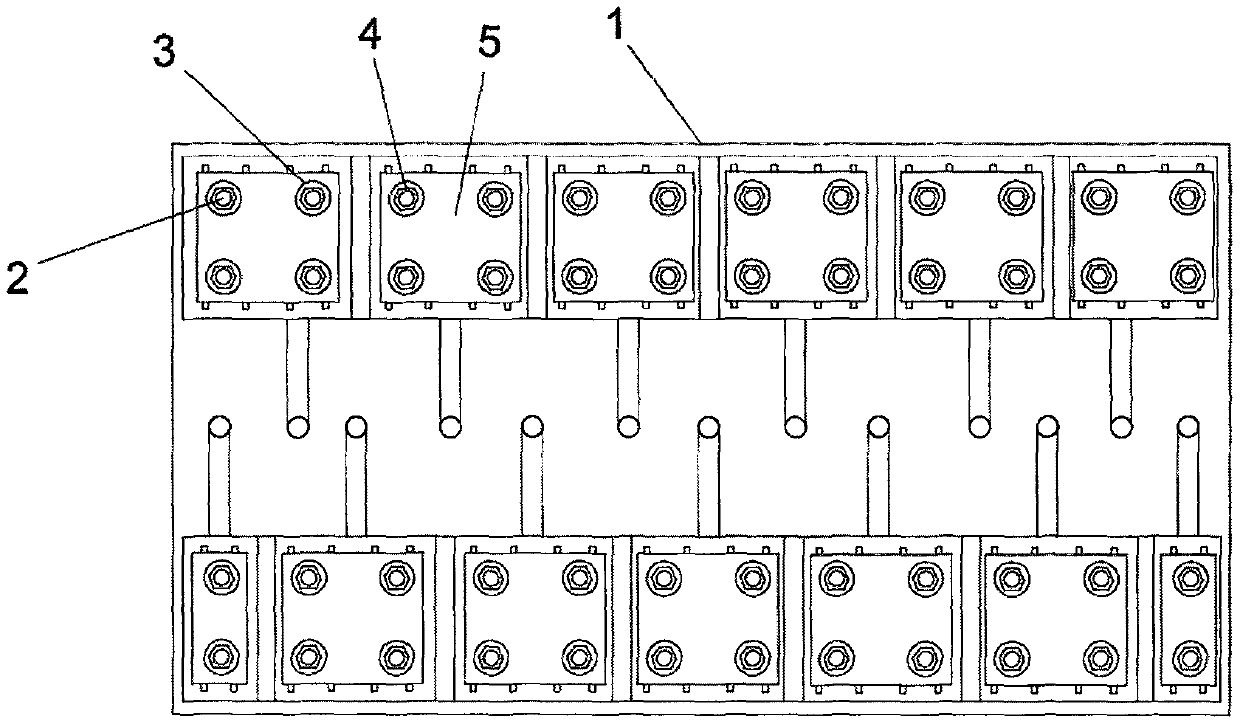

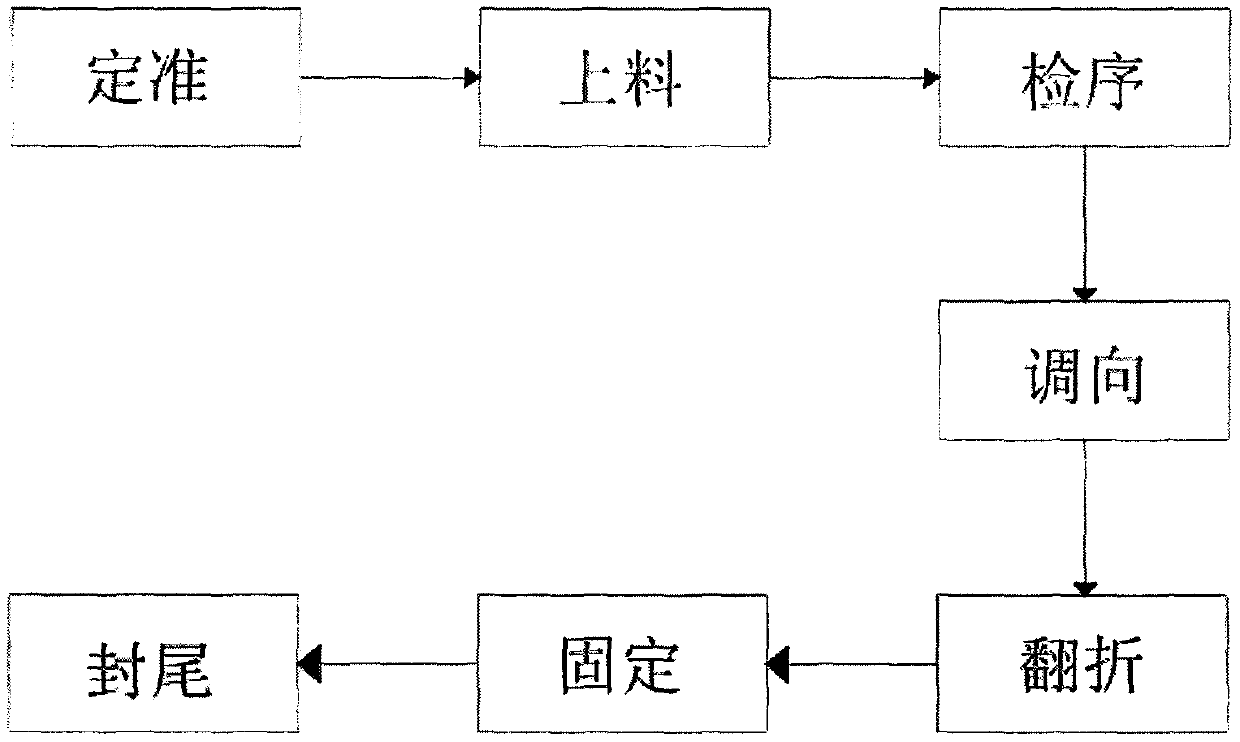

[0019] Such as Figure 1-Figure 2 As shown, a soft-packed lithium battery assembled tab PCB includes a PCB board 1 and a cell with a punched tab. The PCB board 1 is also provided with a number of positive and negative wire grooves, and the cell corresponds to the positive and negative poles. The number of negative wire slots, and the battery cores are inserted into the positive and negative wire slots in turn to fix them. The PCB board 1 has an electrical connection part. The connecting part is electrically connected, and also includes a screw 2, a gasket 3, a nut 4 and a connecting piece 5. The PCB board 1 is provided with a screw hole, and the screw 2 is threadedly connected to the screw hole. The head of the screw 2 Fixedly assembled with the PCB board 1, the connecting piece 5, the gasket 3 and the nut 4 are sequentially arranged at the tail of the screw 2, the tab is directly clamped and fixed by the PCB board 1 and the connecting piece 5, and the nut 4 and the threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com