Electronically controllable braking system and method for controlling the electronically controllable braking system

A technology of electronic control and braking system, which is applied in the direction of braking safety system, braking control system, braking action activation device, etc. It can solve the problems that the trailer control valve is not powered and can no longer be implemented.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

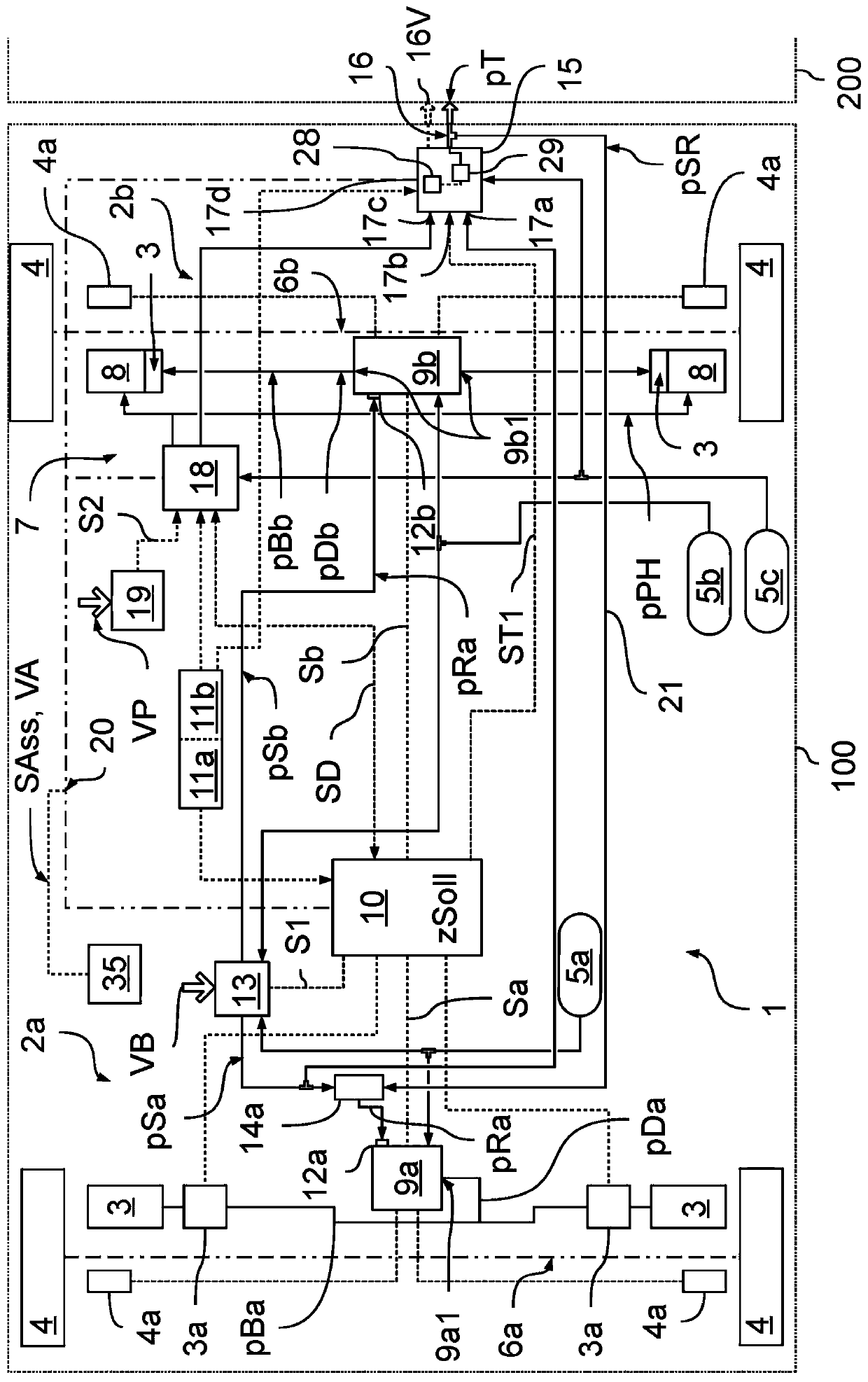

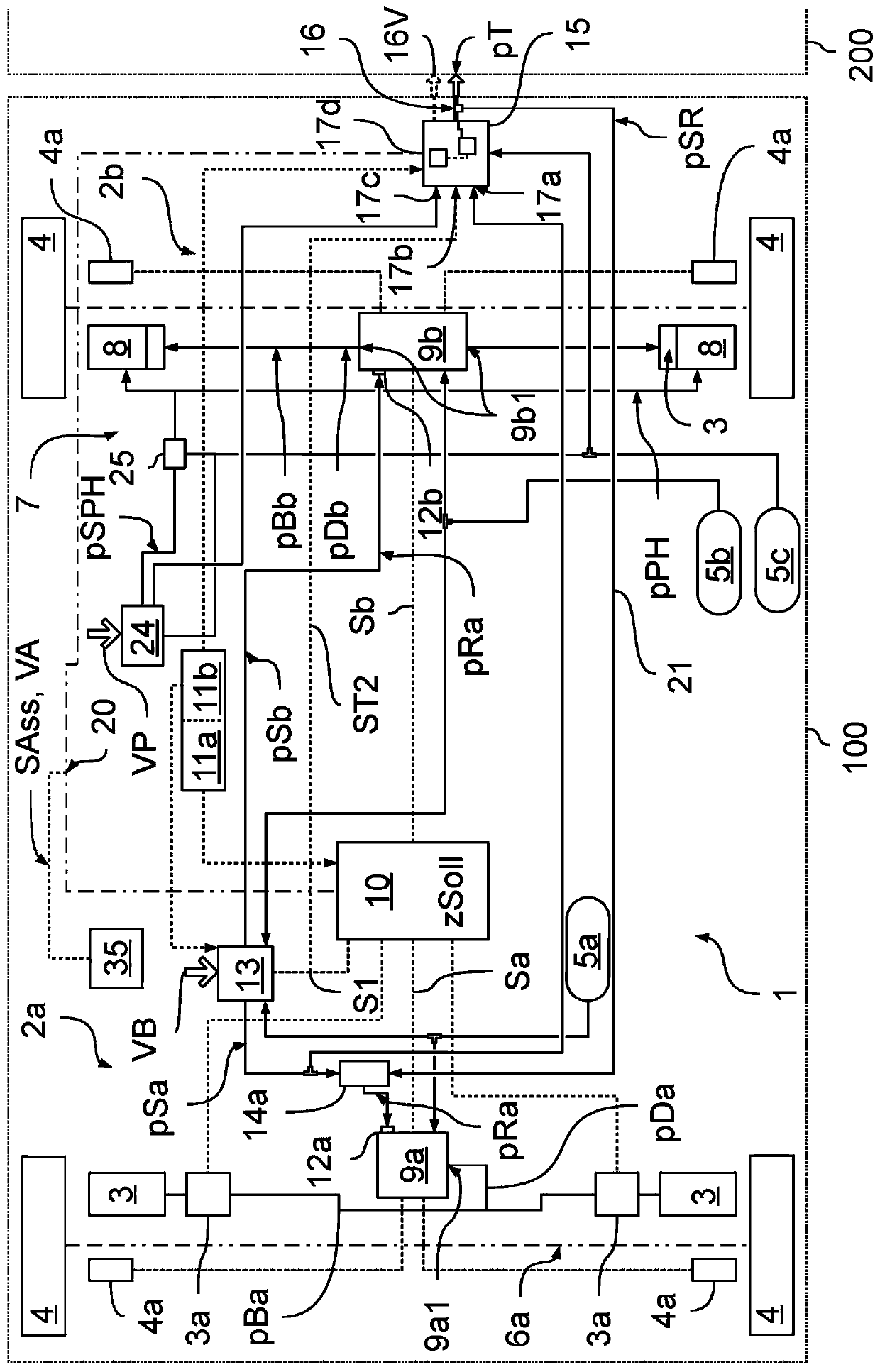

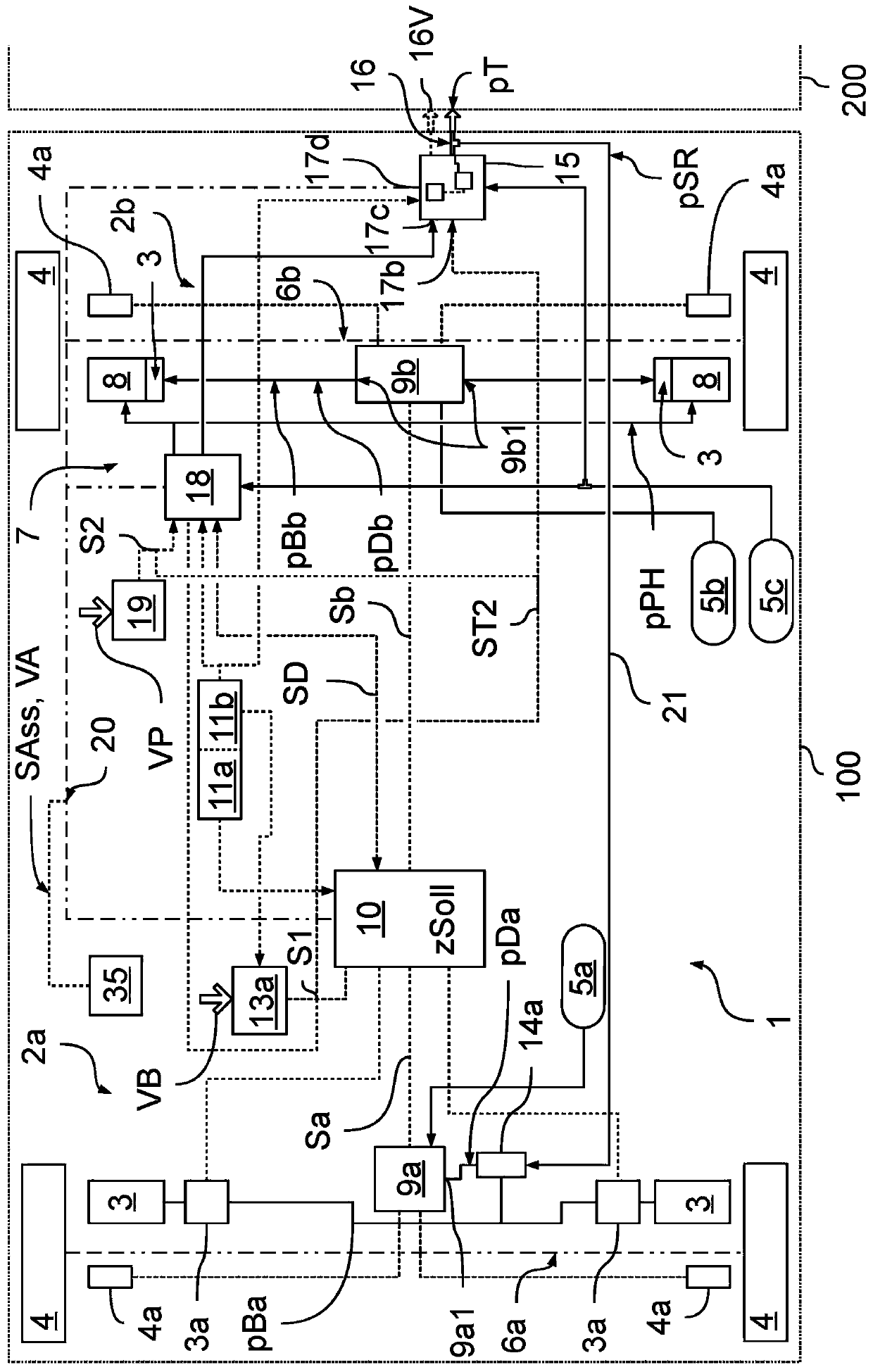

[0064] exist Figure 1a A vehicle 100 is shown schematically with a braking system 1 which can brake in two service brake circuits 2 a , 2 b via service brakes 3 on wheels 4 . The front axle service brake circuit 2a is assigned to the front axle 6a, and the rear axle service brake circuit 2b is assigned to the rear axle 6b. Further axles can also be provided, to which service brake circuits 6 a and 6 b or further service brake circuits are assigned. A pressure medium store 5 a , 5 b is assigned to the service brake circuits 2 a , 2 b per bridge.

[0065] A parking brake circuit 7 is also assigned to the rear axle 6b, wherein the wheels 4 on the rear axle 6b can be braked in the parking brake circuit 7 via a spring accumulator brake 8, so that the wheels of the rear axle 6b 4 Deceleration is possible not only in the rear axle service brake circuit 2 b via the service brake 3 , but also in the parking brake circuit 7 via the spring accumulator brake 8 . For this purpose, a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com