Vacuum freeze-dried material block and preparation method thereof

A vacuum freeze-drying and material block technology, which is applied in food science, food preservation, application, etc., can solve the problems of main material fragmentation, material block easy to loose, and affect product appearance, so as to avoid coarse material breaking and product loosening , good rehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

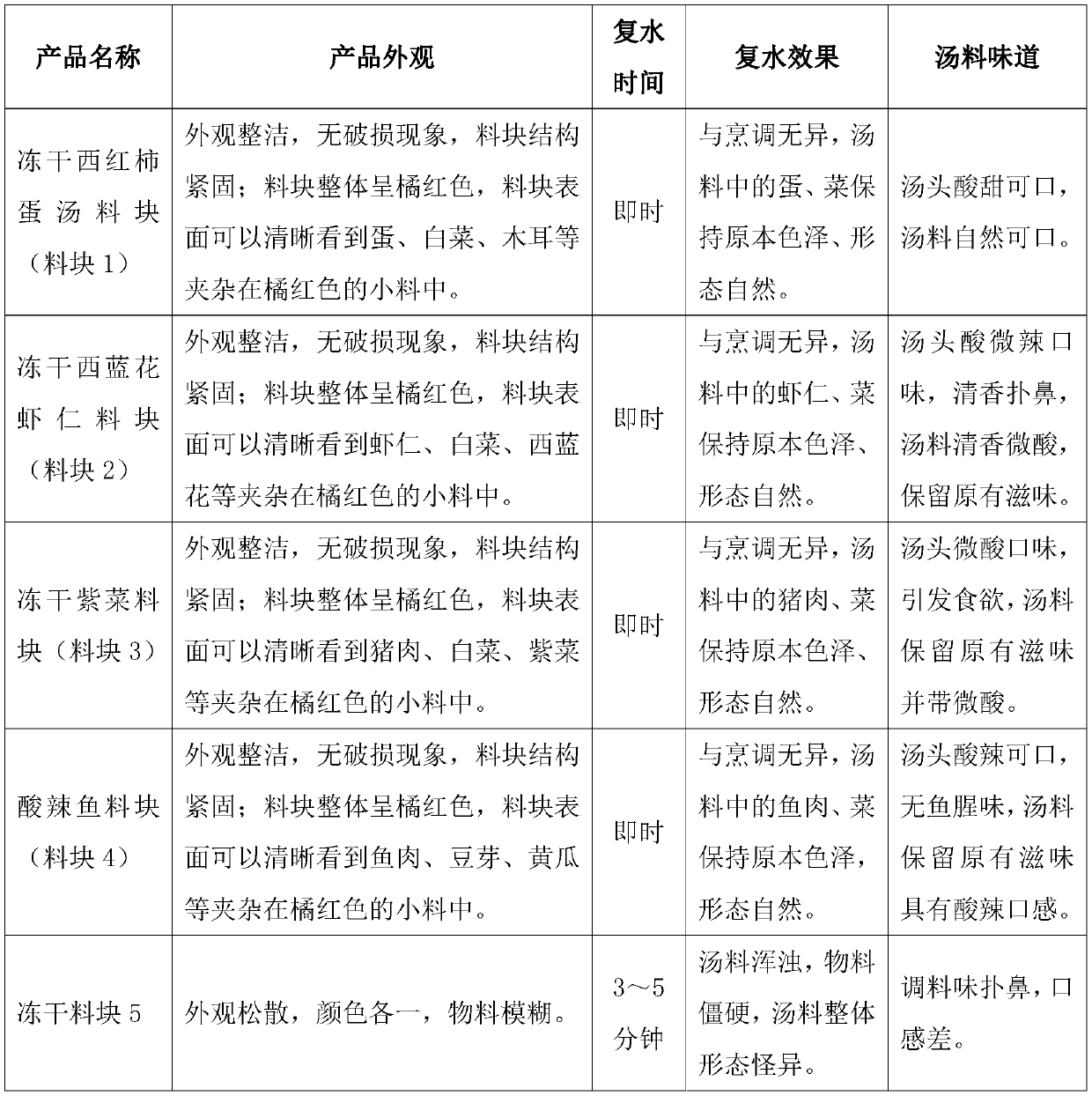

Embodiment 1

[0082] The preparation method of the freeze-dried tomato and egg soup block is to dry the material to obtain the dry material, including,

[0083] Prepare materials, prepare materials for use according to the first material component and the second material component;

[0084]Mixing materials, mixing the second material with the first material to prepare frozen material blocks, wherein the mixing is to add water and stir and mix;

[0085] Vacuum freeze-drying means that frozen material blocks are sublimated and dried into freeze-dried material blocks in vacuum freeze-drying equipment.

[0086] Material preparation, including weighing, is to weigh materials according to their components for future use.

[0087] The first material component, including:

[0088] The main ingredients include 5-70g of tomatoes and 5-70g of cabbage.

[0089] The ingredients include 2-60g of fungus, 2-60g of eggs, and 1-60g of carrot.

[0090] The second material component, including:

[0091] T...

Embodiment 2

[0098] The preparation method of the freeze-dried broccoli shrimp block is to dry the material to obtain the dry material, including,

[0099] Prepare materials, prepare materials for use according to the first material component and the second material component;

[0100] Mixing materials, mixing the second material with the first material to prepare frozen material blocks, wherein the mixing is to add water and stir and mix;

[0101] Vacuum freeze-drying means that frozen material blocks are sublimated and dried into freeze-dried material blocks in vacuum freeze-drying equipment.

[0102] Material preparation, including weighing, is to weigh materials according to their components for future use.

[0103] The first material component, including:

[0104] The main ingredients include 5-70g of tomatoes and 5-70g of cabbage.

[0105] The ingredients include 1-55g of carrot, 2-60g of shrimp, 1-55g of broccoli, 1-2g of pepper ring, and 1-8g of green onion.

[0106] The second...

Embodiment 3

[0114] The preparation method of freeze-dried seaweed material block is that the material is dried to obtain dry material, comprising,

[0115] Prepare materials, prepare materials for use according to the first material component and the second material component;

[0116] Mixing materials, mixing the second material with the first material to prepare frozen material blocks, wherein the mixing is to add water and stir and mix;

[0117] Vacuum freeze-drying means that frozen material blocks are sublimated and dried into freeze-dried material blocks in vacuum freeze-drying equipment.

[0118] Material preparation, including weighing, is to weigh materials according to their components for future use.

[0119] The first material component, including:

[0120] The main ingredients include 5-70g of tomatoes and 5-70g of cabbage.

[0121] The ingredients include 2-110g of laver, 2-62g of pork, and 1-8g of green onion.

[0122] The second material component, including:

[0123]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com